Pack off and Bridge stuck is one of the types of Pipe sticking that may face drilling crew while drilling operations. Our objective in this article is to:

- Understand the the definition and the difference between the hole Pack Off stuck pipe mechanism and Bridge stuck pipe mechanism.

- Identify the stuck pipe mechanism.

- Apprehend the major reasons for suck sticking.

- Learn more about the Pack off / Bridge first actions guidelines.

Pack Off / Bridge Stuck Mechanism & Definition

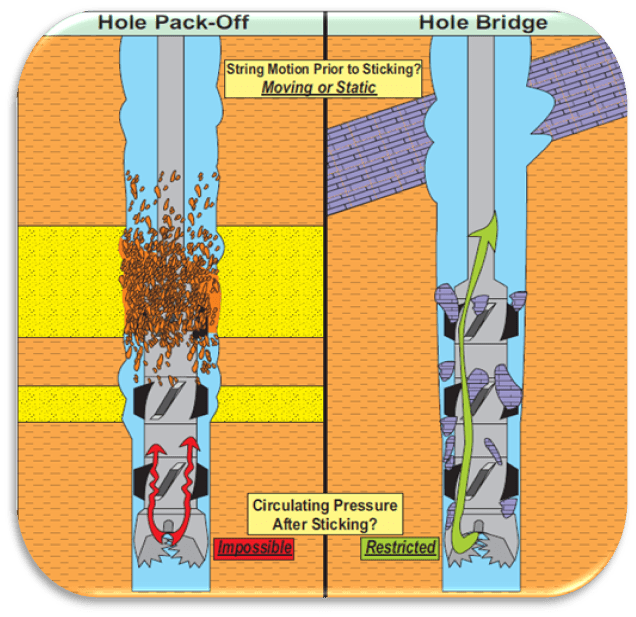

Drilling Pack Off Mechanism: Small pieces of formation, cement or junk settle around the Drill String preventing circulation with no string movement likely.

Hole Bridge Mechanism: Medium to large pieces of formation, cement or junk settle around the Drill String allowing restricted circulation with little to no string movement.

How to Identify Pack Off / Bridge Stuck In Drilling

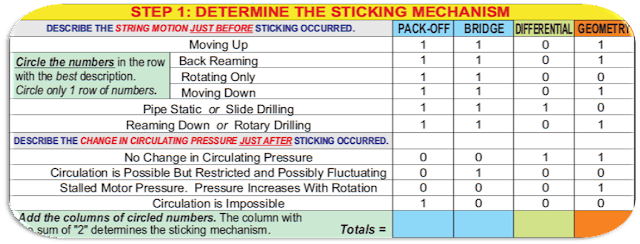

Pack Off / Bridge Stuck Mechanism can be detected easily using the sticking table.

Just follow simple tips:

- Select the situations that you see and circle all the figures in the same row.

- Add all figures for each column.

- If the Pack Off or the Bridge Mechanism column summation is “2”, then proceed to the freeing action of such stuck type.

Different Reasons For Pack Off / Bridge Stuck

There are several reasons which lead to the drilling pack off / bridge sticking. In the same time, this reasons may be a guide for the rig drilling supervisor or the drilling engineer to predict such problem and take in his consideration the preventive actions which may be required. Please feel free to visit each link to recognize the types, preventive actions, Indications, and freeing procedures of each type of Pack Off / Bridge.

- Inadequate hole cleaning:

- Well bore instability:

- Geo-Pressured Shale

- Hydro-Charged Shale

- Reactive Shale

- Overburden Stress

- Tectonic Stress

- Unconsolidated Formation

- Fractured Formation

- Plastic Formation

Drilling Packing Off / Bridge Stuck Freeing Actions

After Identifying the Stuck Pipe Mechanism, Immediately we shall start our first action. We must consider that time is a major factor in freeing the drilling pack off / bridge stuck problem.

- At the first signs of the Drill String torquing up and trying to pack-off, the pump strokes should be reduced by half. This will minimize pressure trapped should the hole pack-off. Excessive pressure applied to a drilling pack off will aggravate the situation. If the hole cleans up, return flow to the normal rate.

- If the string packs off, immediately stop the mud pumps and bleed down the standpipe pressure (Note: not possible with a non-ported float valve). When bleeding pressure down from under a pack-off, control the rate so as not to “U” tube solids into the Drill String in case they plug the string.

- Leave low pressure (less than 500 psi) trapped below the drilling pack off. This will act as an indicator that the situation is improving should the pressure bleed off.

- Holding a maximum of 500 psi on the standpipe and with the string hanging at its free rotating weight, start cycling the Drill String up to maximum make-up torque. At this stage do not work the string up or down.

- Continue cycling the torque, watching for pressure bleed off and returns at the shale shakers. If bleed off or partial circulation occurs, slowly increase pump strokes to maintain a maximum of 500 psi standpipe pressure. If circulation improves continue to increase the pump strokes.

- If circulation cannot be regained, work the pipe between free up and free down weight. DO NOT APPLY EXCESSIVE PULLS AND SET DOWN WEIGHTS AS THIS WILL AGGRAVATE THE SITUATION (50k lb max). Whilst working the string continue to cycle the torque to stall out and maintain a maximum of 500 psi standpipe pressure.

- DO NOT ATTEMPT TO FIRE THE DRILLING JARS IN EITHER DIRECTION.

- If circulation cannot be established increase the standpipe pressure in stages up to 1500 psi and continue to work the pipe and apply torque.

- If the pipe is not free once full circulation is established, commence jarring operations in the opposite direction to the last pipe movement. Once the pipe is released rotate and clean the hole prior to continuing the tripping pipe.

Case Study For Drilling Packing Off – Bridge Stuck

Hole Pack-off due to wrong tripping procedures:

- Whilst RIH for mud conditioning trip prior to running 7” casing liner (One of Types Of Casing), the Drill String got stuck at 10,499 ft in the reservoir formation. A set-down weight of 50 k Ib was applied, followed by pick-up to 50 kIb over-pull. The operation was repeated with 50 klb slack-off followed by 50 klbs over-pull before the string was confirmed stuck, cost to resolve the issue was estimated to be $ 400,000 with more than 10 days NPT.

References:

- Drillers Stuck Pipe Drilling Data Handbook