Mechanical Pipe sticking is when any part from the Drill String such as Drill Pipe, Heavy Weight Drill Pipe HWDP, Drill Collars, Drilling Bit, or Bottom Hole Assembly BHA is stuck in a borehole due to mechanical reasons such as cutting accumulation, junk, extensive cement cutting and changing drill String geometry and cannot be recovered from the bore without damage to the drill pipe (API drill pipe specs). It can occur for various reasons, as will be discussed below. Check also (stuck pipe calculation).

What Is The Real Mechanical Stuck Pipe Causes

We will discuss below the leading causes of Mechanical Stuck Pipes. You can easily visit each link for more details about the tips for preventive actions, indications, and first action for each type of mechanical stuck pipe.

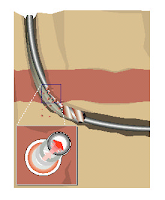

Key Seating

Key Seating is caused by the Drill Pipe rotating against the borehole wall at the same point and wearing a groove or key seat in the wall. During a tripping pipe out of the hole, the Bottom Hole Assembly BHA may be pulled into one of these grooves, which may be too small to pass. This type of sticking is likely to happen in a soft formation while dropping angle.

The Key seating can also occur at the casing shoe if a groove is worn and causes a mechanical stuck for casing pipes.

Key Seat Stuck Pipe Prevention, Indications, Freeing Tips

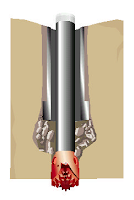

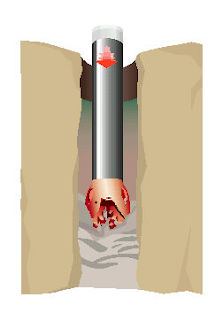

Undergauge Hole

The Under gauge Holes can easily cause a Mechanical Pipe Stuck, as it happens after the Drilling Bits and the Stabilizers gauges get worn while drilling abrasive rock, so the following section using the same Drilling Bit will produce an undergauge hole. If it was decided to run new in gauge Drilling Bit after that, running in the last Undergauge section will have difficulty and a reaming procedure will be required to pass this Under gauge section.

If it was decided to run quickly without reaming, the Drilling Bit can jam in the Under gauge hole and become stuck.

Undergauge Hole Stuck Pipe Prevention, Indications, Freeing Tips

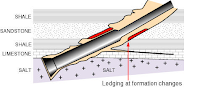

Ledges and Doglegs

Ledges and Doglegs are one of the causes of mechanically stuck pipes. We can define ledges as follows: The well bore passes through rock of varying types, and ledges develop at the interfaces between layers of differing hardness.

Closely spaced ledges decrease the effective diameter of the hole and produce a “shouldered” hole surface. The stiff casing string requires a smooth, more in-gauge hole diameter for free passage and not to stuck. In addition, Doglegs can be defined as follows: While drilling a well bore, the characteristics of the rock cause the Drilling Bit to be deflected and can result in a change in Azimuth. Likewise, sudden changes in angle can cause a kink in the well bore direction when drilling with a directional Bottom Hole Assembly. Sharp deviations in wellbore direction are called doglegs.

Ledges and Doglegs Stuck Pipe Prevention, Indications, Freeing Tips

Metal Junks Dropped Or Parted Cause Mechanical Stuck Pipe

We mean by junk any material, tool, or piece of equipment that may fall from the surface of downhole Bottom Hole Assembly BHA and equipment. The junk may jam the Drill String and easily produce a good junk stuck. This type of mechanical stuck pipe usually occurs:

- Due to poor housekeeping on the drilling rig floor.

- The hole cover is not being installed.

- Downhole equipment failure.

- Drill String Failure

Metal Junk Stuck Pipe Prevention, Indications, Freeing Tips

Collapsed Casing Mechanical Stuck

The casing collapses either if pressure conditions exceed its original rated collapse pressure or the original collapse pressure rating of the casing is no longer valid due to casing wear and/or corrosion. Casing wear due to friction or corrosion decreases the effective collapse pressure rating of the casing

through decreased wall thickness. Collapse is often discovered when the Bottom Hole Assembly BHA is run into the hole and hangs up inside the casing.

Collapsed Casing Mechanical Stuck Prevention, Indications, Freeing Tips

Mechanical Stuck Pipe In Cement Blocks

The Drill String becomes jammed in the hole by cement blocks falling around the drill string. This mechanism typically occurs when hard cement becomes unstable around the casing shoe, open-hole CMT squeeze plugs, and kick-off Cement plugs.

Cement Blocks Mechanical Stuck Prevention, Indications, Freeing Tips

Mechanical Stuck Pipe In Green Cement

When the Drill String is inadvertently run into cement, the cement can flash set. The top of the cement may be higher than the prognoses. The increase in pressure generated by the Bottom Hole Assembly BHA surge causes the cement to flash set.

Circulation is attempted with the bottom of the Drill String in soft cement. The increase in pressure causes the cement to flash set. A high penetration rate is used when cleaning out recently set cement; below is un-set cement, which flash sets.

Green Cement Mechanical Stuck Prevention, Indications, Freeing Tips