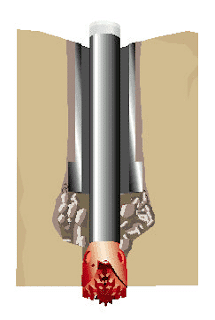

Stuck Pipe In Cement Blocks Cuttings

The Drill String becomes jammed in the hole by cement blocks cuttings falling around the Drill String.

This mechanism occurs typically when :

Hard cement becomes unstable around the casing shoe, open-hole squeeze plugs, and Sidetrack plugs.

Preventative Action

- Allow sufficient curing time for cement before attempting to Sidetrack or drill out (check also: sidetrack Drilling).

- Ream casing shoe and open hole plugs thoroughly before drilling ahead.

- Limit casing rat hole length to minimize a source of cement block cuttings.

- Slow the tripping pipe speed down before the Bottom Hole Assembly BHA enters the casing shoe or the plug depth.

- The use of fiber additives to the cement can increase its integrity.

- Maintain sufficient distance between the paths of platform (platform rigs) wells to reduce the possibility of cement block cuttings from adjacent well bores.

Rig Site Indications For Stuck-In Cement Cuttings

- Circulation is unrestricted.

- Cement fragments.

- Rotation and downward movement may be possible.

- Erratic torque.

Freeing Cement Blocks Stuck

See First Actions For Mechanical Stuck

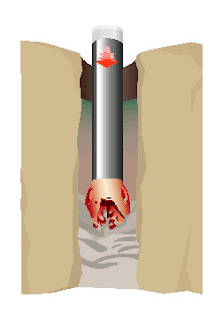

Stuck Pipe In Soft Green Cement

When the Drill String is inadvertently run into green cement, the cement can flash set. The top of the cement may be higher than proposed. The increase in pressure generated by the BHA surge causes the cement to flash set.

Circulation is attempted with the bottom of the Drill String in soft green cement. The increase in pressure causes the cement to flash set. A high penetration rate is used when cleaning out recently set cement; below is un-set cement which flash sets.

This stuck type occurs typically:

While running into the hole to dress off the cement.

Preventative Action to avoid such stuck pipe types

- Do not rely solely on surface samples.

- Know the cement setting time, but do not assume it will be set when you trip into the hole.

- Know the calculated top of cement (TOC) before tripping in the hole, but always expect it to be higher.

- Do not rely on the weight indicator to find the top of the cement.

- If the cement is not set, you may not see any indication on the weight indicator when you run into it.

- In large hole sizes, begin washing down two stands above the theoretical top of the cement.

- Consider starting to ‘wash through’ 3-4 stands above the theoretical cement top in small hole sizes.

- If a set down weight is observed when tripping in the hole after a cement operation, pull back 2 stands before attempting circulation.

- Control drill when cleaning out green soft cement.

- Consider pretreating the mud system with drilling chemicals before drilling out the cement.

Rig site indications For Stuck In Green Cement

- Increase in pump pressure leading to inability to circulate.

- Loss of string weight.

- A sudden decrease in torque.

- Soft Green cement in mud returns discoloration of mud.

Freeing Soft Green Cement Stuck Pipe

Bleed off any trapped pump pressure. Jar up with the maximum trip load. Attempt to establish circulation.