The low-temperature API filter press, operated at room temperature and low pressure, is used for measuring fluid loss only with Water Based Mud. In brief, the API filter press test procedure pressurizes a sample of mud in a chamber while the volume of filtrate that passes through filter paper over a specified period is measured. The quality and thickness of the filter cake deposited on the filter paper are also checked after the device has been dismantled for cleaning.

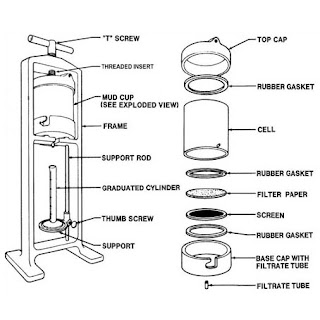

API fluid loss is conducted at a surface temperature at 100 psi pressure and is recorded as the number of milliliters lost in 30 min. The device comprises a mud cell pressurized with a CO2 cartridge using a pressure gauge and regulator. The mud cell comes in three parts: cylindrical body, base with filtrate discharge tube, and top with pressurization system. The mud cell sits in a frame, and the filtrate is collected in a graduated glass measuring cylinder.

Besides measuring fluid loss control and filter cake quality, filtrate from the API filter press is used for some of the mud check chemical analysis, so it is essential to make sure that the filter press components are clean and dry, with no traces of contaminants that could affect chemical analysis results (e.g., salt crystallization).

The Procedures Of Drilling Mud Fluid Loss Testing

The following procedure is used for measuring fluid loss control at ambient temperatures:

- Check that the rubber gasket is seated correctly in the base of the filter press mud chamber, insert the circular gauze frame, and place Whatman No. 50 filter paper on top of the gauze frame.

- Place a rubber gasket on top of the filter paper, engage the pins on the cylindrical body of the mud chamber with the slots in the base, and twist firmly to lock the assembly together.

- Fill the mud chamber with mud, keeping the air gap at the top minimum.

- Place the mud chamber in the filter press frame, check that the rubber gasket is seated correctly in the mud chamber lid, and place it over the cylindrical body of the mud chamber.

- Turn the screw in the filter press frame to lock and seal the lid firmly down on the mud chamber.

- Place a graduated measuring cylinder on the adjustable platform below the mud chamber and adjust the height so that filtrate can be collected from the discharge tube in the base of the mud chamber.

- Insert a new CO2 cartridge in the pressure assembly on the lid of the mud chamber. 2

- Adjust the pressure regulator to apply 100 psi to the mud chamber and record the start time.

- Measure the spurt loss volume recovered in the graduated measuring cylinder during the first few seconds if it is significant.

- Check the pressure gauge regularly to ensure 100 psi is maintained throughout the 30-minute test period.

- When the 30-minute test period is over, close the pressure regulator, pull the red bleed-off knob to release the pressure in the mud chamber, and record the volume of filtrate collected in the graduated measuring cylinder, which is reported as fluid loss in milliliters.

- Carefully dismantle the mud chamber without damaging the filter cake on the filter paper.

- Remove the filter paper and gently rinse off the surface mud on the filter cake.

- Measure the thickness of the filter cake to the nearest 1/32 nd of an inch, and note any relevant observations about filter cake quality (e.g., firm, slick, etc.).

- Use the filtrate collected in the graduated measuring cylinder for the chemical analysis part of the mud checks.

- Remove the used CO2 cartridge from the pressure assembly.

- Wash the filter press components thoroughly and leave them to dry in preparation for future tests.

Why Fluid Loss Control Is Important?

Fluid loss control is not so important for surface hole sections, but it is important for deeper sections because it gives an indication of the mud filtrate that invades the formation. Drilling fluids with poor fluid loss control (i.e. high fluid loss) produce thick filter cakes that can encourage Differential Stuck Pipe and other hole problems. Drilling fluids with good fluid loss control (i.e. low fluid loss) produce thin filter cakes that improve drilling performance.