Additives are chemical compounds added in small quantities to change the physical properties of cement slurry and/or the set cement. Most cementing chemical additives are available either in solid or liquid form. Most of the cement additives available at present have been developed by specialized cementing Companies, although increasingly, products from independent chemical manufacturers are offered to the oil and gas Industry.

The three major specialist suppliers of cementing additives are Halliburton Cementing Chemicals, Dowell Schlumberger Additives (DS), and Byron & Jackson (BJ). Nowsco and Western Company, late-comers to the cementing scene, are offering alternative products to those of the majors.

Some of the products have a limited shelf-life or show variations in their effect on cement slurry properties between batches. Further points to note are the side effects on other properties, synergistic behavior between different additives, and response varying with cement brands. This implies that extensive testing is essential to arrive at a slurry composition with requisite properties and that this be done with samples taken from all ingredients to be used for the cementing job (Cementing in drilling) on hand, including the mix water.

Dosing Cementing Chemical

Additives can be dosed in three essentially different ways:

- Dry blending with cement. Mixing a relatively small quantity of a powdery product, typically 1%v, into a large matrix is problematic and can easily result in a poor, inhomogeneous distribution. This method, therefore, is not recommended.

- Dosing of the additives in the mix water affords good control over the actual rates applied and ensures a consistent treatment. Waste is incurred because, as a contingency, the volume of prepared mix water is usually larger than needed for the job. The simplicity of the operation and the accurate dosing make this the preferred route.

- Metering of additives in liquid form into the mix water tanks of the cement unit when filling up. This avoids the waste of the mix water dosing but requires a reliable, often complicated, metering system able to stand the rigors of a cementing operation. This method, therefore, can be recommended only for advanced and integrated operations.

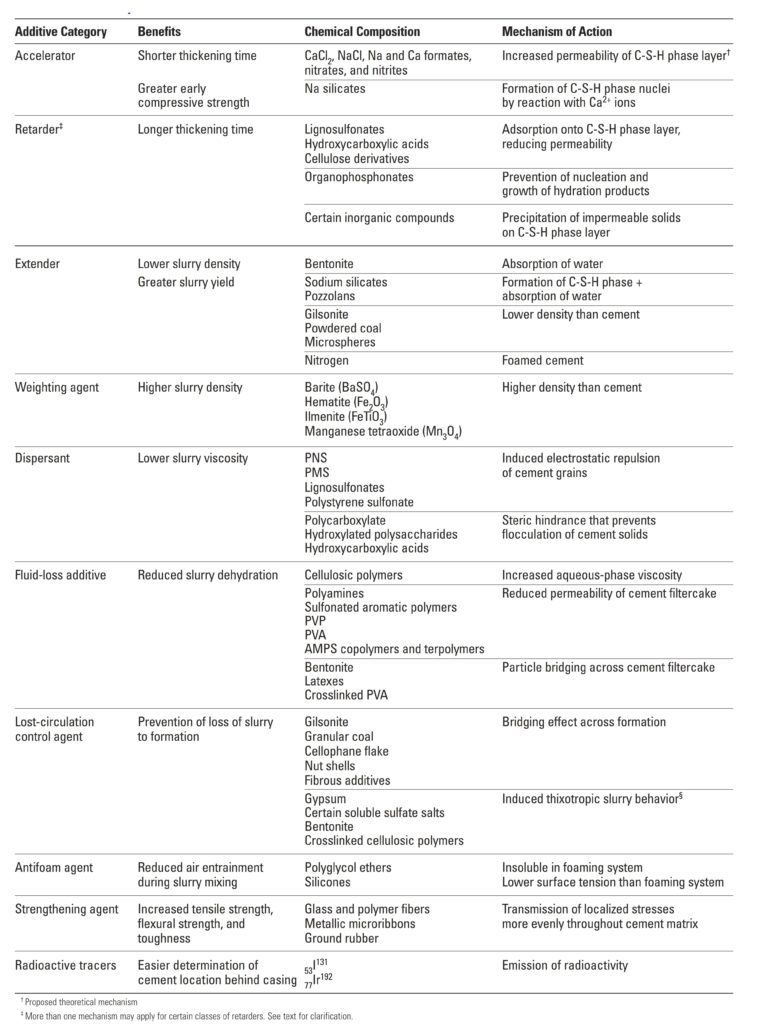

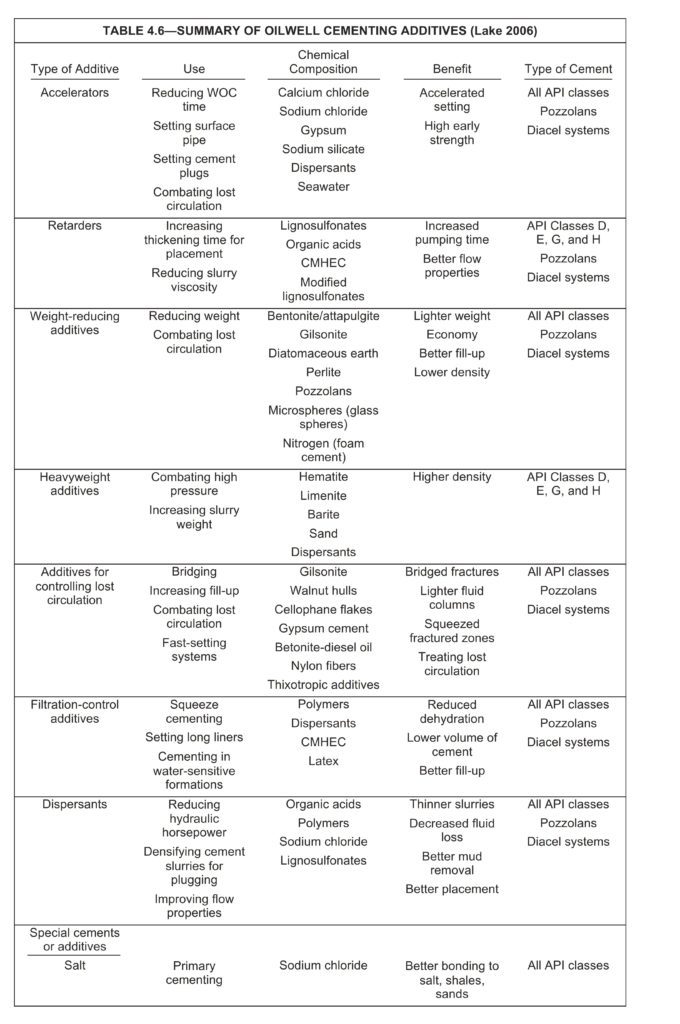

Cementing Accelerators Chemicals

Products to shorten the thickening time of the cement slurry and accelerate strength development in situations where low temperatures would lead to excessive waiting-on-cement times. The most commonly used accelerators are calcium and sodium chloride in dosages of 2%-4% and 5%-10% by weight of cement (bwoc), respectively, dissolved in the mix water.

Aluminum sulfate is a very effective accelerator, which needs to be moderated by adding ferrous sulfate. However, its thixotropic effect makes it less attractive for most applications. This adversely affects displacement and leads to unacceptably high ECD in Drilling, potentially inducing circulation losses or fracturing.

The article on Cement Slurry Accelerators explains the different accelerator types used in cement additives, their mechanism, and their chemistry.

Cementing Retarders Additives

These products are applied to achieve the opposite effect of accelerators, increasing thickening time to a level required by the temperature/pressure adequate for the job. Many different types of retarders are available from cement Contractors and chemical manufacturers alike. Most retarders are characterized by an exponential response in the thickening time of the cement slurry, that is at low dosage rates the effect is rather small, increasing exponentially with a further chemical addition. Therefore, these products should only be used over a certain concentration range.

The different types comprise:

- Sodium chloride at concentrations above 18% by weight of water (bwow)

- Lignosulphonates and derivatives

- Cellulose and sugar derivatives

- Polyhydroxy organic acids

- Organo phosphonates

Typical dosage rates are in the range of 0.25%-0.75% bwoc.

The retarding effect is temperature-dependent, and most commercial products can be used only in a given temperature range. A common side-effect of a retarder is the reduction of slurry viscosity and yield point (check also Yield Point In Drilling Mud Formula) because of its dispersive action.

In the Cement Retarders article, we explained in detail its mechanisms and the most common chemicals used in oil and gas wells.

Cement Extenders Additives

Cement extenders are routinely used to accomplish one or both of the following.

- Reduce slurry density: A reduction of slurry density reduces the hydrostatic pressure during cementing. This helps to prevent induced lost circulation because of the breakdown of weak formations. In addition, the number of stages required to cement any oil & gas well may be reduced.

- Increase slurry yield: Extenders reduce the amount of cement required to produce a given volume of set product. This results in a greater economy.

Extenders Categories

Extenders can be classified into one of three categories, depending upon the mechanism of density reduction and/or yield increase. Often, more than one type of extender is used in the same slurry.

- Water extenders: Clays and various water viscosifying agents allow the addition of more water to achieve slurry extension. Such extenders maintain a homogeneous slurry and prevent the development of excessive free water.

- Low-density aggregates: This varied category consists of materials with densities lower than that of Portland cement (3.20 g/cm3). The slurry density is reduced when significant quantities of such extenders are present.

- Gaseous extenders: Nitrogen or air can be used to prepare foamed cement with exceptionally low densities yet sufficient compressive strength.

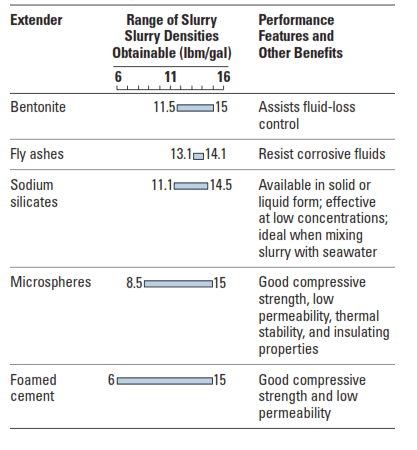

Table 2 lists the common extenders, with general information regarding their performance characteristics.

Cement Weighting Agents Chemicals

In some cases, it may be necessary to increase the gradient of the cement slurry where the normal one is insufficient to maintain well control through pressure (over)balance. Raising the gradient will also increase the solids-to-water ratio and, therefore, affect an increase in the rheology.

The most common cement weighting agents are as follows:

- Ilmenite

- Hematite

- Barite

- Manganese tetraoxide.

In the Cement Weighting Agents article, we have handled the common chemicals, mechanisms & side effects of each agent.

Cement Dispersants Additives

Treatment with a dispersant aims to reduce the viscosity of the cement slurry, thereby promoting turbulent flow at lower pump rates. As a side effect, dispersants also cause retardation and reduction of thixotropic properties.

Three different types are available;

- Lignosulphonate or lignin derivatives

- Synthetic polymers such as polyacrylates

- Organic acids.

Combining a dispersant with a fluid loss reduction additive exhibits strong synergy. The Cement Slurry Dispersants article explains its mechanisms, chemicals & side effects on cement.

Fluid Loss Control Agents

Neat cement slurries exhibit a very high, essentially uncontrolled fluid loss in the standard API test of Spec. IDA. For most cementations, some measure of fluid loss control is highly desirable to prevent excessive slurry dehydration. However, the presence of an immovable mud cake in itself may serve this purpose to a large extent. Slurry dehydration will increase viscosity and gels, leading to high pump pressures and equivalent circulation densities.

Most of the fluid loss reducers in use are either a cellulose derivative or a polymeric type and tend to increase slurry viscosity/consistency, which is usually countered by adding some dispersant. The operator should be aware that using these additives will, most of the time, result in a prolonged setting of the cement and, more importantly, a more extensive transition period.

Like retarders, fluid loss control additives exhibit a temperature-dependent action within an envelope. We recommend visiting our Cement Fluid Loss Control Agents Guide as we explain its mechanisms and chemicals in more detail.

Cement Expanding Agents Additives

The purpose of these agents is to reduce the shrinkage of setting cement. Two types of expanding additives are available:

- Chemical or crystal growth expanders. Calcium sulfate hemihydrate and calcined magnesium oxides are the most prominent compounds. They produce their expanding effect well after the cement has set.

- Gas-generating expanders. (Hydrogen) gas is generated in situ during the gelling stage of the cement slurry. The expansion takes place as a consequence of reduced hydrostatic pressure in this stage, where the weight of the cement column is progressively carried by the gel structure. The most common material used for this purpose is aluminum powder. An added advantage of this system is the good bonding of cement to the casing, which provides an effective gas-tight seal. However, the safety aspects of hydrogen should not be overlooked, where explosive limits of H2/air mixtures are between 1.5 and 98% v.

Using chemical expanding agents in combination with surfactants in general is not recommended. The latter reduces the volumetric reduction of cement slurry in the hydration stage, which is more effective for improving sealing than these agents’ expansion in a later stage.

Lost Circulation Prevention Agents For Cement

The loss of circulation during a primary cementing job is a serious problem that often necessitates remedial cementing. Circulation losses tend to occur in vuggy or cavernous formations, particularly in highly fractured, incompetent zones that break down at relatively low hydrostatic pressures.

Usually, the operator will have experienced some circulation difficulties during drilling; thus, measures can be taken to prevent their occurrence during cementing.

Bridging materials

Many lost-circulation problems are controlled by adding materials that physically bridge over fractures and block weak zones. Such materials increase the resistance of the zone to pressure parting. As a general rule, they are chemically inert with respect to Portland cement hydration.

Granular materials such as gilsonite and granular coal are excellent bridging agents. They are also used extensively as cement extenders. They are added in specific concentrations. Other granular materials used less often include ground walnut or pecan shells, Formica § chips (available in various particle sizes), coarse bentonite, and corn cobs.

Another important bridging agent is cellophane flakes. As the cement slurry encounters the lost-circulation zone, the flakes form a mat at the fracture face. They can also plate out across high-permeability zones. The thickness of the flakes is usually 0.02 to 0.06 mm, and the planar dimensions are less than 1 cm on each side. The normal concentration of cellophane flakes is between 0.125 and 0.500 lbm/sk.

More recently, fibers made from glass or synthetic polymers have been added to cement slurries to prevent lost circulation (Messier et al., 2002). As the cement § Formica is a registered trademark of Formica Corp. slurry enters the lost-circulation zone, the fibers associate to form a mat that promotes cement filter cake development. This technique has been used successfully for both primary and remedial cementing. The concentration of fibers in the slurry normally varies from 2 to 3 lbm/bbl.

Thixotropic Cement

When vugular or cavernous zones are so large that bridging agents are ineffective, thixotropic cements are often indicated. When such slurries enter the formation, they are no longer subjected to shear; as a result, they gel and become self-supporting. Eventually, the thixotropic cement plugs the lost circulation.

Miscellaneous Cement Additives

There are several materials added to cement slurries that do not fit into any general category. These include antifoam agents, fibrous additives to improve cement durability, radioactive tracing agents, and mud decontaminants.

Antifoam Agents Additives

Many cement additives can cause the slurry to foam during mixing. Excessive slurry foaming can have several undesirable consequences. Slurry gelation can result, and loss of hydraulic pressure during pumping can occur owing to cavitation in the mixing system. In addition, air entrainment may cause higher-than-desired slurry densities.

During slurry mixing, a densitometer is used to help field personnel proportion the ingredients. If air is present in the slurry at the surface, the system’s density “cement + water + air” is measured. Because the air becomes compressed downhole, the densitometer underestimates the true downhole slurry density. Antifoam agents are usually added to the mix water or dry-blended with the cement to prevent such problems.

Antifoam agents produce a shift in surface tension, alter the dispersibility of solids, or both so that the conditions required to produce a foam are no longer present. In general, antifoams must have the following characteristics to be effective.

- Insoluble in the foaming system

- A lower surface tension than the foaming system (Lichtman and Gammon, 1979)

The antifoam agent functions largely by spreading on the surface of the foam or entering the foam. Because the film formed by the spread of antifoam on the surface of a foaming liquid does not support foam, the foam situation is alleviated.

Antifoam Additives Categories

In oil & gas well cementing, two classes of antifoam agent additives are commonly used: polyglycol ethers and silicones. Very small concentrations can achieve adequate foam prevention, usually less than 0.1% BWOW.

Polyethylene glycol is most frequently used because of its lower cost and is effective in most situations; however, it must be present in the system before mixing. Field experience has shown that the post-addition of polyethylene glycol is inefficient, and in some cases, foam stabilization can result.

The silicones are highly effective antifoam agents. They are suspensions of finely divided particles of silica dispersed in polydimethylsiloxane or similar silicones. Oil-in-water emulsions at 10% to 30% activity also exist. Unlike the polyglycol ethers, silicones will destroy a foam regardless of when they are added to the system.

Strengthening Agents Additives

Fibrous materials additives are available that, when added to any oil & gas well cements in concentrations between 0.15% and 0.5% BWOC, increase the cement’s resistance to the stresses associated with perforating, hydraulic fracturing, and formation movement (Carter et al., 1968; Shi et al., 1995). Such materials transmit localized stresses more evenly throughout the cement matrix. Nylon fibers, with fiber lengths up to 1 in., are commonly used.

More recently, metallic microribbons were introduced to improve the mechanical properties of set cement (Baret et al., 2002). The microribbon concentration is usually about 1.5% by volume of slurry. The set cement has significantly improved impact resistance, toughness, and tensile strength at this concentration. This system is particularly effective for kickoff plugs (Chapter 14).

Another material that dramatically improves the impact resistance and flexural strength of oil & gas well cement is particulated rubber (unpublished data, F.E. Hook, 1971). This material is usually added in concentrations up to 5% BWOC. Latex-modified cement also exhibits improved flexural strength (Chapter 7). More recently, the principle of adding flexible particles to cement has been developed further. The well-cementing industry is paying more attention to set cement mechanical properties other than compressive strength. During a well’s lifetime, the cement sheath can be exposed to stresses that may cause conventional set cement to fail. Adding flexible particles improves the set cement’s resistance to such stresses, providing better long-term zonal isolation (Le Roy-Delage et al., 2000; Bosma et al., 2000).

Radioactive Tracing Agents Additives

The radioactive compounds are sometimes added to cement slurries to determine their location behind the casing more easily. Radioactive tracers were once used to determine the fill-up or top of the cement column; however, temperature surveys and cement bond logs have largely assumed this function. In addition, radioactive slurries are still occasionally used in remedial cementing to locate the slurry after placement. A base radiation log is run before the cement job to measure the natural formation radioactivity. After the job is completed, another radiation log is generated, and the location of the remedial slurry is determined by comparison with the base log.

The most common radioactive agents for well cementing are 53 I 131 (half-life: 8.1 days) and 77 Ir 192 (half-life: 74 days). The iodine is generally available as a liquid. Sand or glass beads tagged with iridium 192 are often available in areas where tracers are used with hydraulic fracturing fluids.

Mud Decontaminants Additives

Certain chemicals in drilling fluids, such as tannins, lignins, starches, celluloses, and various chemically treated lignosulfonates, can severely retard a Portland cement slurry. To minimize such effects if the cement slurry and the mud become intermixed, chemicals such as paraformaldehyde or blends of paraformaldehyde and sodium chromate are effective (Beach and Goins, 1957).

Summary Of Cementing Chemical Additives

Reference:

- Schlumberger Well Cementing, Erik B. Nelson and Dominique Guillot, Sheel Cementing Manual