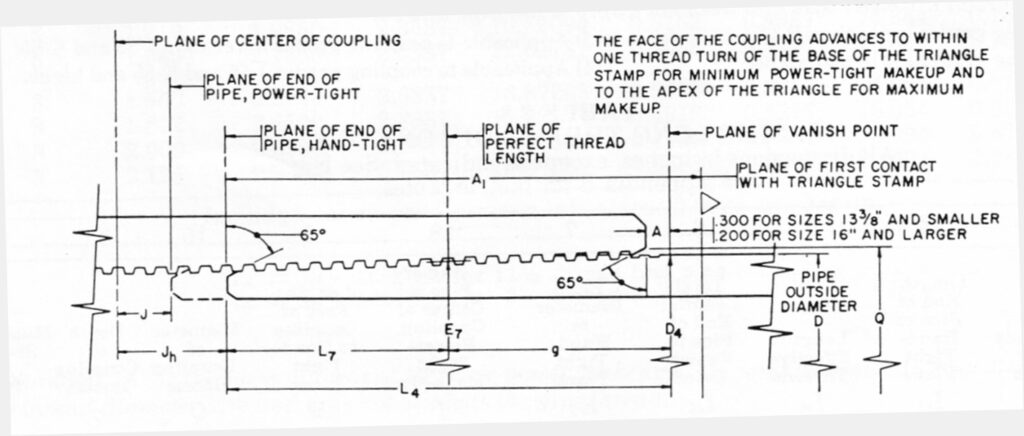

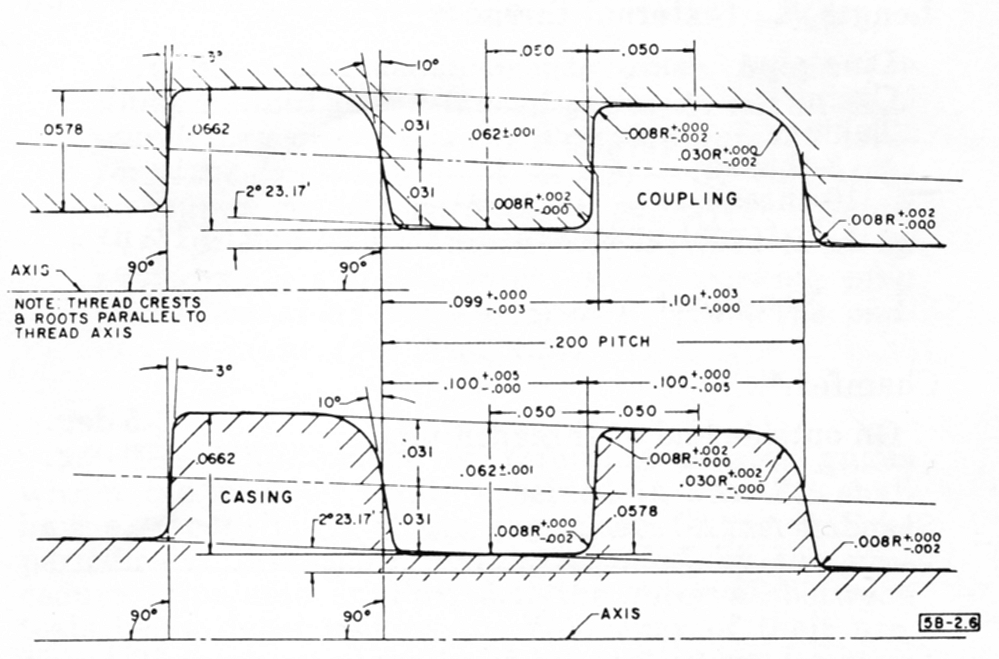

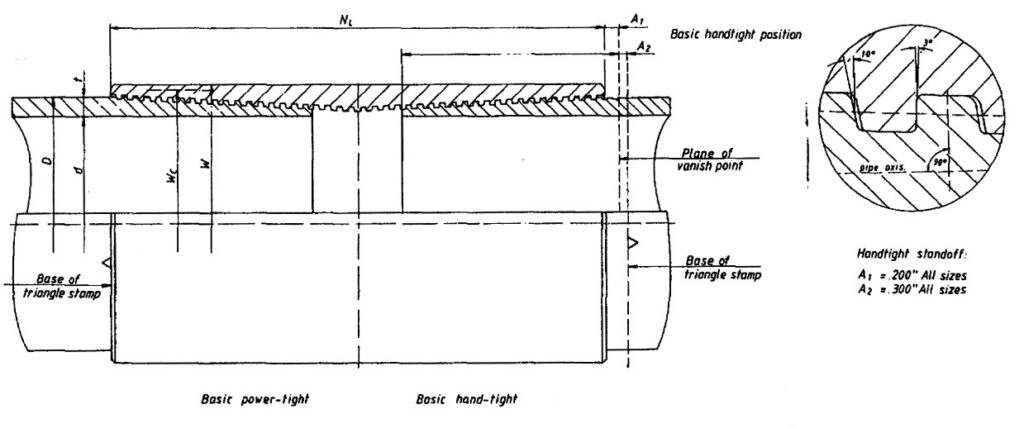

In API Buttress Connection Data sheet shows that the casing is externally threaded on both ends of non-upset pipe. The single lengths are joined by an internally threaded coupling. – The thread profile has flat crests and roots parallel to the taper cone with angles 3° and 10° to the vertical of the pipe axis; and 5 threads per inch on a 0,0625 inch per inch taper for sizes 13% inch and smaller, and 0,0833 inch per inch for sizes 16 inch and larger.

API Connections

The American Petroleum Institute (API) has adopted several connections. The API designation indicates that a connection design (generally developed by private industry) has been donated to the public with the American Petroleum Institute assuming stewardship. The API connections include 8rd (pronounced “eight round”-implying eight threads per inch), 10rd, Buttress (BTC), and Extreme-Line (XL) designs. API Standards 5B and 5CT contain the geometric, performance, and gauging specifics for the available API connections and address tubing and casing sizes 1.050″ through 20″.

Buttress Connections

API Buttress (BTC) connections are available in pipe sizes 4-1/2″ through 20″ (Figure 1 & 2). BTC connections larger than 13-3/8″ OD can be subject to cross threading. Extreme care in the field can ensure the proper make-up of the larger sizes. The shear resistant, large thread cross-section and easy running characteristics of BTC make it the workhorse of high tensile casing designs.

Adequate sealability and clearance need to be checked as with any connection application. Improved threading practices over the years have improved the sealability of BTC. When controlled tin plating is applied, an economical, high tensile, and very leak resistant connection is achieved.

Preparations Hints:

- Clean the connection from any dirts with high pressure water. It is not recommended to use oil as it may leave residue on the connection

- Drift the joints from pin to box

- Secure the joints with thread protector

- Check the upper and lower string that you will connect to the Buttress connection (X-overs – Subs – Completion Tools – etc …)

- Most of oil and gas companies will perform full inspection of casing or tubing including the connection. If this is not available, go through visual inspection

- Note that connecting different material may cause problems with time. Therefore, make sure that all the string with the same metallurgy.

- Refer to API RP 5A3, to check the compatible thread compound. Many experts recommend using API modified thread compound

- You don’t need to sink the thread with grease, just a simple thin film of grease on the half of the connection will be enough

Making Up The Buttress Connection

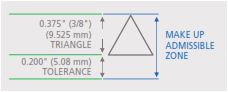

Make-up torque values for buttress thread casing connections should be determined by carefully noting the torque required to make up each of several connections to the base of the triangle, then using the torque value thus established, make up the balance of the pipe of that particular weight and grade in the string ( Check also: Casing Running Procedure).

- In Data sheet Min Make Up For API Buttress connection: One full thread turn before triangle base.

- Maximum Make up: Triangle Base

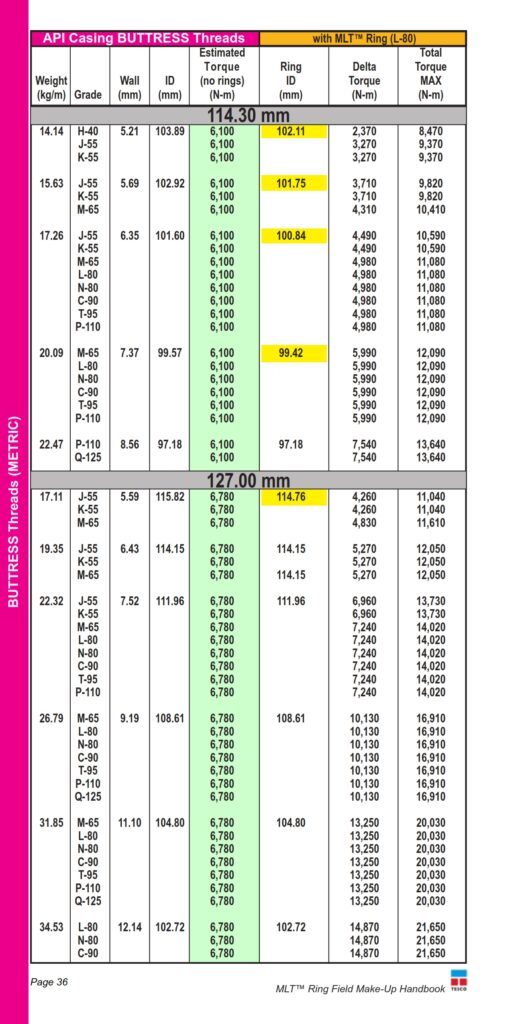

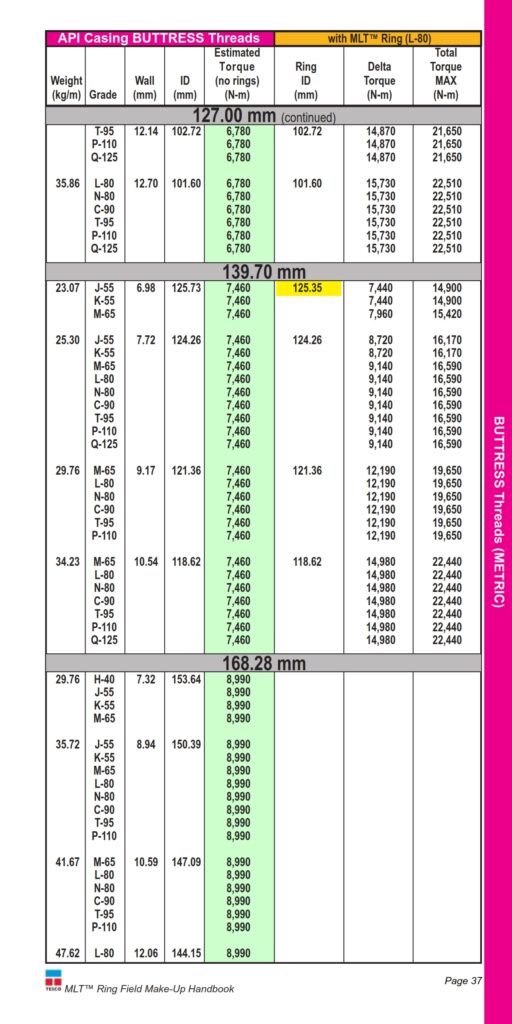

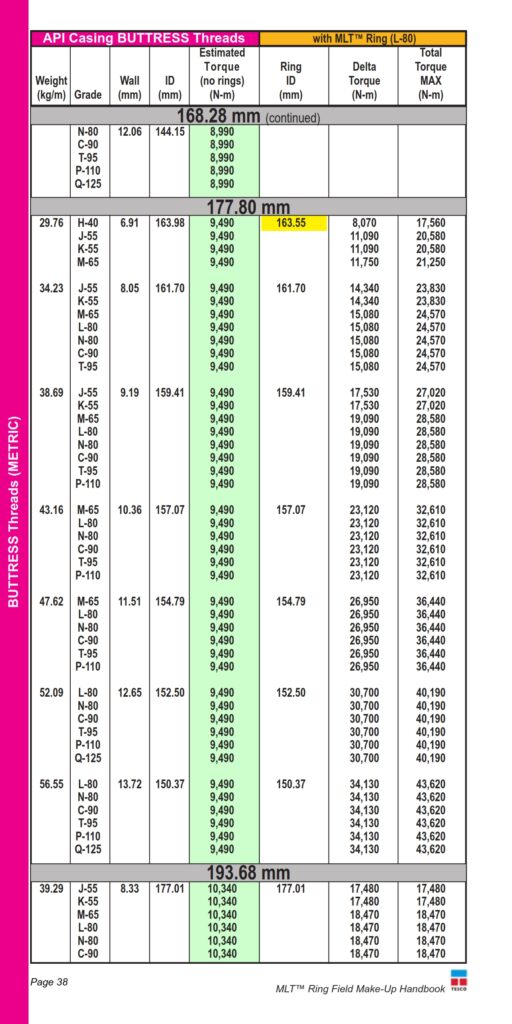

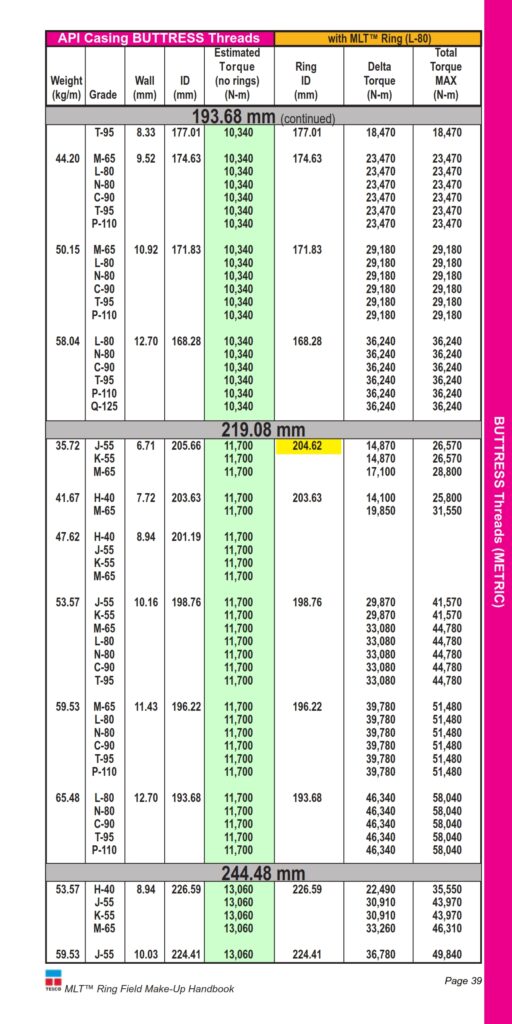

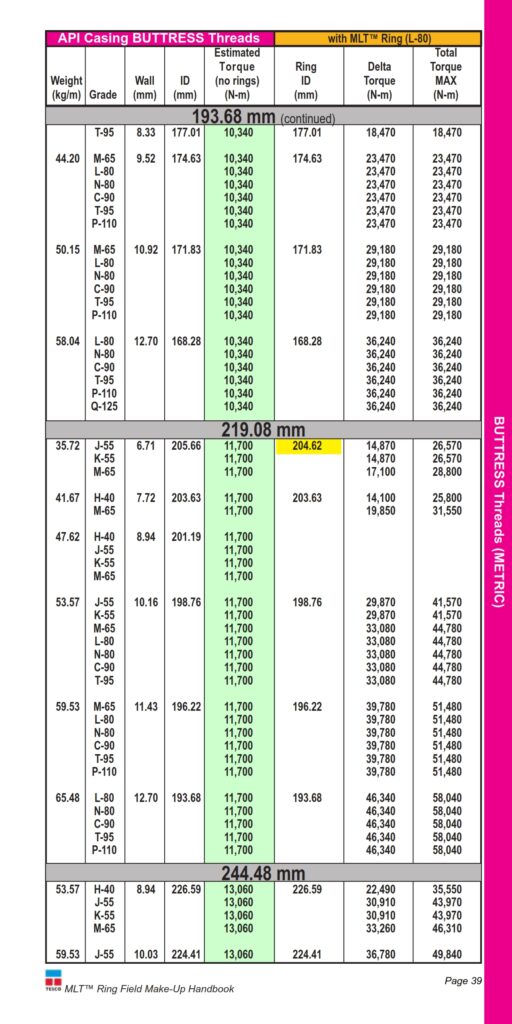

Maximum Spin while making up Buttress coneection should not exceed 15 RPM. Verticality while making up process is important, therfore you will need a stapper in such job. Below values shall be as a guidelines while making up the Buttress Connections

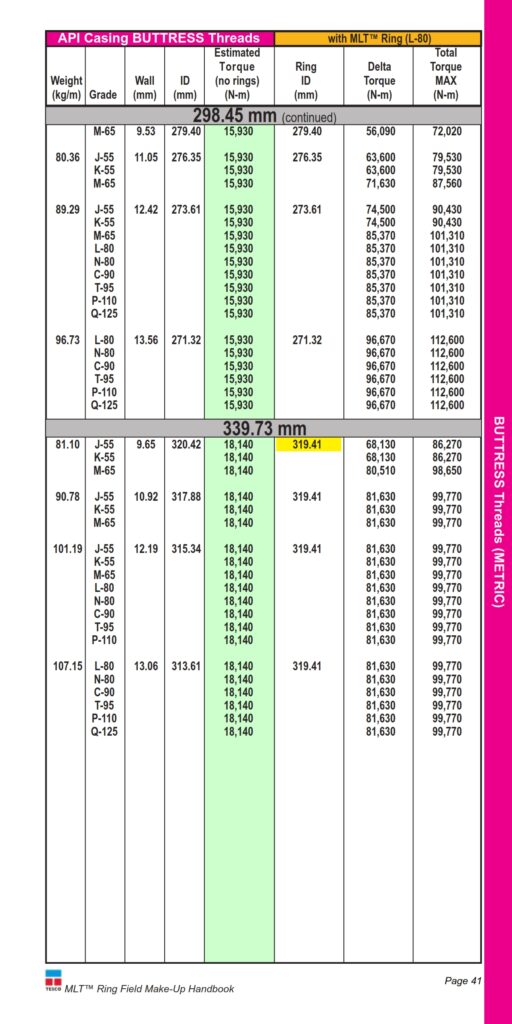

API Buttress Casing Connections Make Up Loss Datasheet

| OD inch | OD mm | Make Up Loss (in) | Make Up Loss (mm) |

| 4 1/2 | 114.3 | 3.9375 | 100 |

| 5 | 127 | 4.0625 | 103.2 |

| 5 1/2 | 139.7 | 4.125 | 104.8 |

| 6 5/8 | 168.3 | 4.3125 | 109.5 |

| 7 | 177.8 | 4.5 | 114.3 |

| 7 5/8 | 193.8 | 4.6875 | 119.1 |

| 8 5/8 | 219.1 | 4.8125 | 122.2 |

| 9 5/8 | 244.5 | 4.8125 | 122.2 |

| 10 3/4 | 273 | 4.8125 | 122.2 |

| 11 3/4 | 298.4 | 4.8125 | 122.2 |

| 13 3/8 | 339.7 | 4.8125 | 122.2 |

| 16 | 406.4 | 4.8125 | 122.2 |

| 18 5/8 | 473 | 4.8125 | 122.2 |

| 20 | 508 | 4.8125 | 122.2 |

Data Sheet | Coupling Of The API Buttress Connection Dimensions

| D [in] | D [mm] | Nom Wt Ibs/ft | d [in] | d [mm] | t [in] | t [mm] | W [in] | W [mm] | Wc [in] | Wc [mm] | N1 [In) | N1 [mm) | Threads per inch |

| 4.5 | 114,30 | 10,50 | 4,051 | 102,90 | 0,224 | 5,70 | 5,000 | 127,00 | 4,875 | 123,83 | 8,875 | 225,43 | 5 |

| 4.5 | 114,30 | 13,50 | 3,917 | 101,50 | 0,248 | 6,30 | 5,000 | 127,00 | 4,875 | 123,83 | 8,875 | 225,43 | 5 |

| 4.5 | 114,30 | 11,60 | 3,996 | 97,20 | 0,291 | 7,40 | 5,000 | 127,00 | 4,875 | 123,83 | 8,875 | 225,43 | 5 |

| 4.5 | 114,30 | 15,10 | 3,826 | 99,50 | 0,338 | 8,60 | 5,000 | 127,00 | 4,875 | 123,83 | 8,875 | 225,43 | 5 |

| 5 | 127,00 | 13,00 | 4,496 | 114,20 | 0,251 | 6,40 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5 | 127,00 | 15,00 | 4,409 | 112,00 | 0,295 | 7,50 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5 | 127,00 | 18,00 | 4,275 | 108,60 | 0,362 | 9,20 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5 | 127,00 | 21,40 | 4,125 | 104,80 | 0,437 | 11,10 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5 | 127,00 | 23,20 | 4,047 | 102,80 | 0,476 | 12,10 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5 | 127,00 | 24,10 | 4,000 | 101,60 | 0,500 | 12,70 | 5,563 | 141,30 | 5,375 | 136,53 | 9,125 | 231,78 | 5 |

| 5.5 | 139,70 | 15,50 | 4,948 | 125,70 | 0,275 | 7,00 | 6,050 | 153,67 | 5,875 | 149,23 | 9,250 | 234,95 | 5 |

| 5.5 | 139,70 | 17,00 | 4,893 | 124,30 | 0,303 | 7,70 | 6,050 | 153,67 | 5,875 | 149,23 | 9,250 | 234,95 | 5 |

| 5.5 | 139,70 | 20,00 | 4,775 | 121,30 | 0,362 | 9,20 | 6,050 | 153,67 | 5,875 | 149,23 | 9,250 | 234,95 | 5 |

| 5.5 | 139,70 | 23,00 | 4,673 | 118,70 | 0,413 | 10,50 | 6,050 | 153,67 | 7,000 | 149,23 | 9,250 | 234,95 | 5 |

| 6 5/8 | 168,28 | 20,00 | 6,051 | 153,70 | 0,287 | 7,30 | 7,390 | 187,71 | 5,875 | 177,80 | 9,625 | 244,48 | 5 |

| 6 5/8 | 168,28 | 24,00 | 5,921 | 150,40 | 0,350 | 8,90 | 7,390 | 187,71 | 7,000 | 177,80 | 9,625 | 244,48 | 5 |

| 6 5/8 | 168,28 | 28,00 | 5,791 | 147,10 | 0,417 | 10,60 | 7,390 | 187,71 | 7,000 | 177,80 | 9,625 | 244,48 | 5 |

| 6 5/8 | 168,28 | 32,00 | 5,673 | 144,10 | 0,476 | 12, 10 | 7,390 | 167,71 | 7,000 | 177,80 | 9,625 | 244,48 | 5 |

| 7 | 177,80 | 23,00 | 6,362 | 161,60 | 0,314 | 8,00 | 7,656 | 194,46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 | 177,80 | 26,00 | 6,275 | 159,40 | 0,362 | 9,20 | 7,656 | 194,46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 | 177,80 | 29,00 | 6,181 | 157,00 | 0,409 | 10,40 | 7,656 | 194,46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 | 177,80 | 32,00 | 6,094 | 154,80 | 0,452 | 11,50 | 7,656 | 194;46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 | 177,80 | 35,00 | 6,007 | 152,60 | 0,496 | 12,60 | 7,656 | 194,46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 | 177,80 | 38,00 | 5,921 | 150,40 | 0,539 | 13,70 | 7,656 | 194,46 | 7,375 | 187,33 | 10,000 | 254,00 | 5 |

| 7 5/8 | 193,70 | 26,40 | 6,968 | 177,00 | 0,328 | 8,36 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 29,70 | 6,877 | 174,70 | 0,375 | 9,56 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 33,70 | 4,799 | 121,90 | 0,430 | 10,97 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 39,00 | 6,625 | 168,30 | 0,500 | 12,75 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 42,80 | 6,500 | 165, 10 | 0,562 | 14,33 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 45,30 | 6,437 | 163,50 | 0,595 | 15,17 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 7 5/8 | 193,70 | 47,10 | 6,374 | 161,90 | 0,625 | 15,94 | 8,500 | 215,90 | 8,125 | 206,38 | 10,375 | 263,53 | 5 |

| 8 5/8 | 219,10 | 32,00 | 7,925 | 201,30 | 0,352 | 08,98 | 9,625 | 244,48 | 9,125 | 231,78 | 10,625 | 269,88 | 5 |

| 8 5/8 | 219,10 | 36,00 | 7,822 | 198,70 | 0,400 | 10,20 | 9,625 | 244,48 | 9,125 | 231,78 | 10,625 | 269,88 | 5 |

| 8 5/8 | 219,10 | 40,00 | 7,728 | 196,30 | 0,450 | 11,48 | 9,625 | 244,48 | 9,125 | 231,78 | 10,625 | 269,88 | 5 |

| 8 5/8 | 219,10 | 44,00 | 7,625 | 193,70 | 0,500 | 12,75 | 9,625 | 244,48 | 9,125 | 231,78 | 10,625 | 269,88 | 5 |

| 8 5/8 | 219,10 | 49,00 | 7,515 | 190,90 | 0,557 | 14,20 | 9,625 | 244,48 | 9,125 | 231,78 | 10,625 | 269,88 | 5 |

| 9 5/8 | 244,50 | 36,00 | 8,925 | 226,70 | 0,352 | 08,98 | 10,625 | 269,88 | 10,125 | 257,18 | 10,625 | 269,88 | 5 |

| 9 5/8 | 244,50 | 40,00 | 8,838 | 224,50 | 0,395 | 10,07 | 10,625 | 269,88 | 10,125 | 257,18 | 10,625 | 269,88 | 5 |

| 9 5/8 | 244,50 | 43,50 | 8,759 | 222,50 | 0,435 | 11,09 | 10,625 | 269,88 | 10,125 | 257,18 | 10,625 | 269,88 | 5 |

| 9 5/8 | 244,50 | 47,00 | 8,681 | 220,50 | 0,472 | 12,04 | 10,625 | 269,88 | 10,125 | 257,18 | 10,625 | 269,88 | 5 |

| 9 5/8 | 244,50 | 53,50 | 8,539 | 216,90 | 0,545 | 13,90 | 10,625 | 269,88 | 10,125 | 257,18 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 40,50 | 10,051 | 255,30 | 0,350 | 08,93 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 45,50 | 9,948 | 252,70 | 0,400 | 10,20 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 51,00 | 9,854 | 250,30 | 0,450 | 11,48 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 55,50 | 9,759 | 247,90 | 0,495 | 12,62 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 60,70 | 9,661 | 245,40 | 0,545 | 13,90 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 10 3/4 | 273,10 | 65,70 | 9,559 | 242,80 | 0,595 | 15,17 | 11,750 | 298,45 | 11,250 | 285,75 | 10,625 | 269,88 | 5 |

| 11 3/4 | 298,50 | 47,00 | 11,003 | 279,50 | 0,375 | 9,56 | 12,750 | 323,85 | – | – | 10,625 | 269,88 | 5 |

| 11 3/4 | 298,50 | 54,00 | 10,885 | 276,50 | 0,435 | 11,09 | 12,750 | 323,85 | – | – | 10,625 | 269,88 | 5 |

| 11 3/4 | 298,50 | 60,00 | 10,775 | 273,70 | 0,489 | 12,47 | 12,750 | 323,85 | – | – | 10,625 | 269,88 | 5 |

| 13 3/8 | 339,70 | 54,50 | 12,610 | 320,30 | 0,380 | 9,69 | 14,375 | 365,13 | – | – | 10,625 | 269,88 | 5 |

| 13 3/8 | 339,70 | 61,00 | 12,515 | 317,90 | 0,430 | 10,97 | 14,375 | 365,13 | – | – | 10,625 | 269,88 | 5 |

| 13 3/8 | 339,70 | 68,00 | 12,413 | 315,30 | 0,480 | 12,24 | 14,375 | 365,13 | – | – | 10,625 | 269,88 | 5 |

| 13 3/8 | 339,70 | 72,00 | 12,342 | 313,50 | 0,514 | 13,11 | 14,375 | 365,13 | – | – | 10,625 | 269,88 | 5 |

| 16 | 406,40 | 75,00 | 15,125 | 384,20 | 0,438 | 11,17 | 17,000 | 431,80 | – | – | 10,625 | 269,88 | 5 |

| 16 | 406,40 | 84,00 | 15,007 | 381,20 | 0,495 | 12,62 | 17,000 | 431,80 | – | – | 10,625 | 269,88 | 5 |

| 18 5/8 | 473,00 | 87,50 | 17,755 | 451,00 | 0,435 | 11,09 | 20,000 | 508,00 | – | – | 10,625 | 269,88 | 5 |

| 20 | 508,00 | 94,00 | 19,125 | 485,80 | 0,438 | 11,17 | 21,000 | 533,40 | – | – | 10,625 | 269,88 | 5 |

| 20 | 508,00 | 106,50 | 19,000 | 482,60 | 0,500 | 12,75 | 21,000 | 533,40 | – | – | 10,625 | 269,88 | 5 |

| 20 | 508,00 | 133,00 | 18,732 | 475,80 | 0,635 | 16,19 | 21,000 | 533,40 | – | – | 10,625 | 269,88 | 5 |

API Buttres Connection Selection Do’s & Dont’s In Data Sheet

- Confine BTC to 13-3/8 diameter pipe or less. Short strings of 16 to 20 BTC, with tension design factors greater than 6.0 can be used, but are not justifiable on rigs that have a high day rate. This is due to the difficulty in stabbing and verifying that a proper power tight make-up has been achieved. If fluid tightness to gas or clear liquids is absolutely required, the couplings must be tin plated and made up to at least the base of the triangle.

- Don’t use API casing connections that are coupling weak for internal pressure or axial tension loads (i.e. special clearance BTC and thick wall casing).