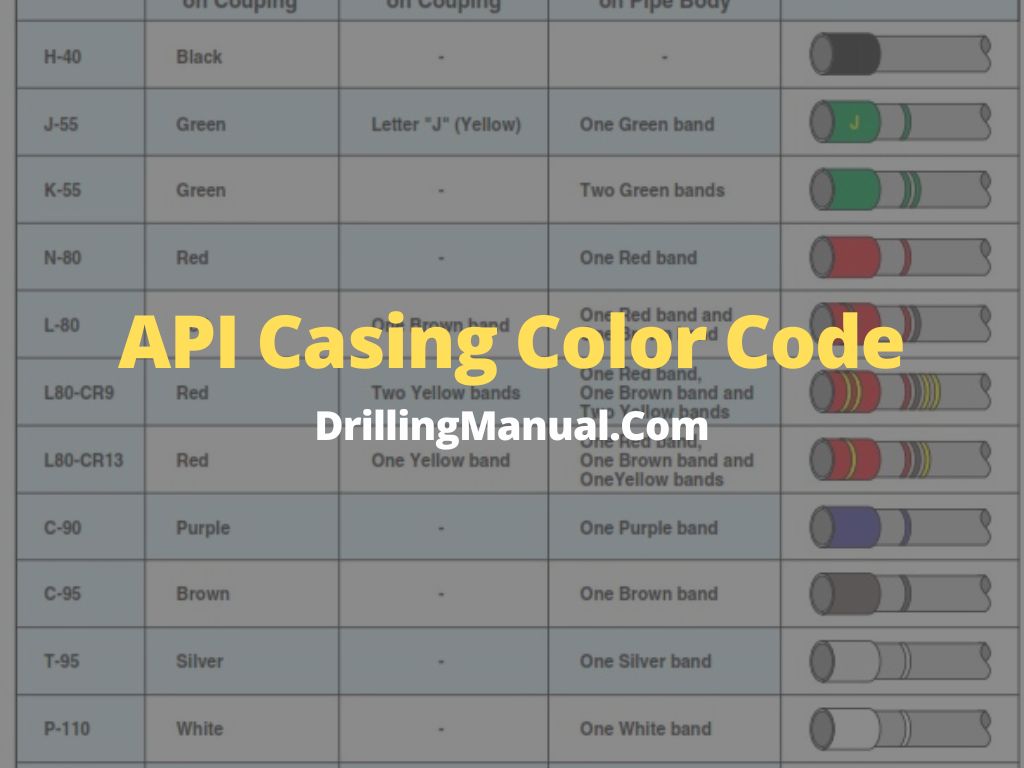

To determine the strength of various casing materials, API has designated defined grades. This grading system consists of a letter and number as P-110, L-80. The number is an arbitrary one (e.g. K-55) representing the min yield strength of the casing (Casing performance Properties), the number is an arbitrary one (e.g. N-80). There are also non-API casings that we use in special cases as deep wells or in high-corrosive environments. The API has defined a color code for the different grades of steel used for making casing and collars. These are shown below.

| Grade | Color Coating on Couping | Color Band on Couping | Color Band on Pipe Body | Drawing |

| H-40 | Black | – | – | |

| J-55 | Green | Letter “J” (Yellow) | One Green band |  |

| K-55 | Green | – | Two Green bands |  |

| N-80 | Red | – | One Red band | |

| L-80 | Red | One Brown band | One Red band and One Brown band |  |

| L80-CR9 | Red | Two Yellow bands | One Red band, One Brown band and Two Yellow bands | |

| L80-CR13 | Red | One Yellow band | This API Casing Color Code had One Red band, One Brown band and One Yellow bands | |

| C-90 | Purple | – | One Purple band |  |

| C-95 | Brown | – | One Brown band |  |

| T-95 | Silver | – | One Silver band |  |

| P-110 | White | – | One White band | |

| Q-125 | Orange | – | One Orange band |  |

In the design of casing and tubing strings, the minimum yield strength of the steel is taken as the basis of all strength calculations

| Grade | Minimum Yield Strength (PSI) | Maximum Yield Strength (PSI) | Min Tensile Strength (PSI) |

| H 40 | 40,000 PSI | 80,000 PSI | 60,000 PSI |

| J 55 | 55,000 PSI | 80,000 PSI | 70-95,000 PSI |

| C 75 | 75,000 PSI | 80,000 PSI | 70-95,000 PSI |

| N 80 | 80,000 PSI | 110,000 PSI | 100,000 PSI |

| L 80 | 80,000 PSI | 95,000 PSI | 100,000 PSI |

| C 90 | 90,000 PSI | 105,000 PSI | 100,000 PSI |

| C 95 | 95,000 PSI | 110,000 PSI | 105,000 PSI |

| P 110 | 110,000 PSI | 140,000 PSI | 125,000 PSI |

| Q 125 | 125,000 PSI | 150,000 PSI | 135,000 PSI |