A back pressure valve (BPV) is a type of valve that we use in drilling & workover rigs to regulate the flow of fluids in a wellhead. Its design allows fluid to flow in only one direction and prevents fluid from flowing back into the wellhead.

Application Of Wellhead Back Pressure Valve

The most critical period during the completion or workover of wells is the removal of the drilling or workover BOP stack or the Christmas tree. When in production, another critical time is during servicing of the Christmas tree whenever penetrating the pressure vessel. In these circumstances, the well must have sufficient barriers to protect personnel from injury. And further, prevent uncontrolled well flow (well kicks).

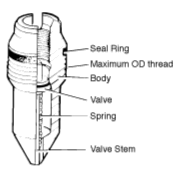

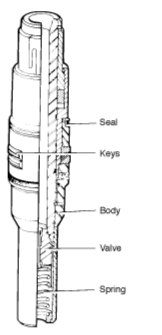

This protection is usually provided by placing barriers in the well bore. These barriers can be either mechanical plugs or plugs in conjunction with an overbalance fluid. With whichever used barrier method, it is standard practice to install a plug or back pressure valve (BPV) into the wellhead (drilling tubing hanger or hanger nipple; see Figures 1 and 2).

Working Principle

Tubing BPVs, one-way check valves, are lockable in the tubing hanger, hold pressure from below, and we can pump through for well control or circulation if required. They have become less widely used in favor of positive or two-way plugs. This is because we cannot generally test from below. In addition, they do not allow testing of the equipment above, e.g., the Christmas tree connection.

Installation Of Back Pressure Valve In The Wellhead

We can set and retrieve these valves by conventional wireline methods where the keys on the lock mandrel, carrying the valve, latch into a landing nipple profile in the tubing hanger; see Figure 2. Alternatively, we can install a two-way hanger plug or wellhead back pressure valve (BPV) furnished with ACME threads.

This is a potentially hazardous operation and should only be carried out by adequately trained personnel.

On Live Wells

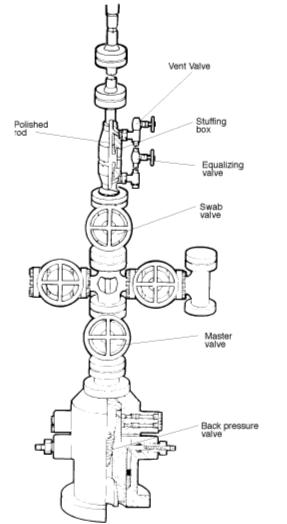

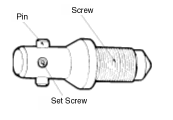

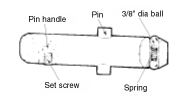

On a live well, we can accomplish this by using a polished rod and an extraordinary lubricator; See Figure 3. In general, the lubricator consists of two stuffing boxes, a vent valve, and an equalizing valve. After working the polished rod through the stuffing box, the BPV is attached to its lower end using an installation/removal tool; See Figure 4. Then we can connect the lubricator to the top of the Christmas tree.

By closing the vent valve and opening the equalizing and swab valves, any well pressure will act on the top and bottom of the rod, allowing it, by means of a friction wrench, to be rotated or moved up and down. We can lower the rod, and install the BPV (with a left-hand square thread) by anti-clockwise rotation. Further anti-clockwise rotation will back off the installation tool from the plug or BPV. Following installation, we remove the rod from the lubricator. The reverse of the above procedure accomplishes the removal of the wellhead back pressure valve (BPV).

We must equalize any pressure below the BPV. Figure 5 shows an equalization tool for this purpose.

On Dead Wells

On dead wells, the plugs may be installed by hand without using the rod lubricator, using either the polished rods or wireline stem to run the plug through the open BOPs or Christmas tree to the tubing hanger. The setting procedure is the same.