Oil & gas blind drilling is the process of drilling at the minimum possible pump rate to conserve drilling fluid stocks while the annulus is topped up with water. If returns begin while drilling, this might indicate that the circulation loss zone has been plugged with drilled cuttings. However, it could also indicate the onset of a kick.

In some areas, blind drilling is common practice as experience has shown that it is a waste of time to attempt to cure mud losses with lost circulation material. Sometimes drilling is carried out with water, with occasional viscous pills to aid hole cleaning, without filling the annulus. It is even possible to do this when drilling fractured carbonate gas reservoirs by continually pumping water down the annulus at a flow rate sufficient to prevent gas kick percolation. A sufficient water supply is then safety critical.

Why Do We Need Blind Drilling In Oil & Gas?

- If the loss zone is in the lower part of the hole section, it will be more wisdom to blind drill this section, attempt to regain the circulation, then proceed to casing running operations.

- If there was a complete loss in the surface hole.

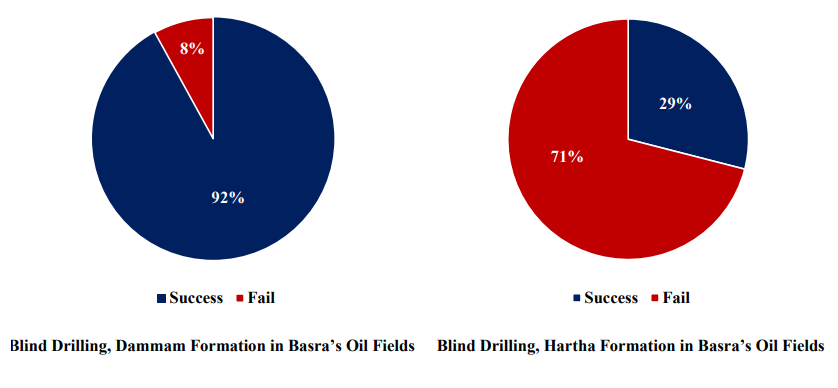

Blind drilling may succeed or fail. And the application of such a technique depends mainly on the field’s previous experience. As an example, In Dammam and Hartha formations in Basra, you will find that the success possibility is highly different (Figure 1).

Procedure

- Prepare enough volume of water, as we will use it instead of drilling fluids

- Prepare sufficient amounts of High viscosity pills

- Drill ahead 30 ft (one drill pipe)

- Pump 30 bbls high viscosity pill to lift, cutting away from the bottom hole assembly.

- Continue drilling ahead in the same manner till finishing one STD

- At each STD, pump 60 bbls of a high-viscosity pill.

- Some oil and gas companies recommend blind drilling one drill pipe with water and another with drilling fluid. In this case, the cost will be elevated due to the high cost of drilling mud.

- If the circulation has been retained, it is highly recommended to circulate the hole till shale shakers clean.

- If there is still no circulation, it is recommended to at least finish the expected loss zone and try to cure it with LCM or cement plugs.

Risks of Blind Drilling In Oil & Gas Wells

- No precise data about the formation lithology.

- Possibility of cutting accumulation around the bottom hole assembly.

- Pipe sticking as there may cutting accumulation.

- Some hole problems can’t be detected as drill pipe washout

- Bit balling may occur due to cutting accumulation, mainly if a clay section follows the loss zone.

- Hole collapse while blind drilling may occur when there is an abnormal formation above the lost circulation zone

References:

- Drilling Strategies to Control Lost Circulation in Basra Oil Fields, Iraq, AADE-18- FTCE- 59

- Aramco Well Control Manual