Bridge plugs are specialty plugging devices that can be set as temporary isolation tools to be retrieved (retrievable) later or installed as permanent plugging and isolation tools (Drillable).

They can be run on a wireline or pipes designed to be set in either casing or tubing. Also, models are available that are set in the casing but can be run through the tubing string.

Bridge Plug Applications

A bridge plug is used when:

- One or more perforated (or weak) zones must be protected under the treated zone.

- The distance between the treated zone and the bottom of the well is too long.

- Multiple zones and selective single zone treating and testing operations include acidizing, hydraulic fracturing, casing cementing, and testing.

- Well Abandonment.

- Remedial Cement Jobs.

When a retrievable bridge plug is used, it is covered with sand before the slurry is pumped. This way, it is protected, and the excess cement in the casing can be drilled out without damaging it.

After retrieving Bridge plug, it is mandatory to perform the required removal, close inspection of the parts is necessary to identify any parts which require replacement.

Specifications

B.Ps are selected depending on the following items:

- Casing size, grade & weight ( 9 5/8″, 7″, …..) that will be set on.

- Max Tool OD.

- Temperature rating.

- Pressure rating.

Bridge Plug Categories & Types

There are two main categories of bridge plugs according to their applications:

- Drillable Type

- Retrievable Type

Also, we can categorize them according to their setting mechanisms:

- Wireline set type

- Mechanical set type

Many production packers can be converted into bridge plugs by slight modifications via the installation of a few specialized tools.

Drillable Type

Drillable plugs are typically used to isolate the casing below the zone to be treated. They are of similar in design to the Cement Retainer, and they can be set on a wireline or a drill pipe. These plugs do not allow flow through the tool.

Retrievable Type

Retrievable bridge plugs are efficiently run and operated tools with the same function as the drillable type. They are generally run in one trip (Tripping pipe) with the Retrievable Packers and retrieved later after the cement is drilled out. Most operators will spot frac sand or acid-soluble calcium carbonate on top of the retrievable plug before doing the cement squeeze job to prevent cement from settling over the top of the retrievable bridge plug.

Thru Tubing Bridge Plug

The thru-tubing bridge plug (TTBP) provides a means of sealing off a certain zone (lower) without the need to retrieve tubing or killing (driller’s method – Wait & weight method) the upper producing zones. This saves time and cost, and there will be no need for a rig. It seals off the well with a high-expansion inflatable rubber segment that can pass through the completion tubing and seal off in the casing below.

The bridge plug is set hydraulically so it can be run on coiled tubing or electric wireline (utilizing the thru-tubing electric wireline setting tool). The inflatable rubber can be set in most ID’s including blank pipe, perforations, slotted casing liners, sand screens, and open holes. It may also be used for permanent lower zone shutoffs or permanent well abandonments.

Other Types In The Market

Iron Bridge Plugs

Iron bridge plugs are designed for use in applications where high pressure, temperature and erosive conditions are present. These plugs feature a robust design and can be set using either conventional coiled tubing or a wireline setting tool. The plug has an internal bypass valve that allows fluid to flow through the plug when needed, while preventing any unwanted leaks or seepage. The internal bypass valve also allows for debris wash-out during retrieval, ensuring the integrity of the plug when it is set.

Composite Bridge Plugs

Composite bridge plugs are designed for applications where extreme temperatures and pressures are present, but they can also be used in low-pressure environments. This type of bridge plug is highly reliable and is typically used in well completions where the casing must be protected from damage caused by downhole fluids. Composite bridge plugs feature an integrated packing element, which creates a seal between the plug body and the surrounding casing or tubing.

WR Bridge Plugs

WR bridge plugs are designed for applications where high temperatures and pressures are present. They feature an innovative design that allows them to be retrieved quickly and easily without any additional tools or equipment. The plug consists of an upper slips, a plug mandrel, a packing element, and lower slips. When deployed, the upper slips expand against the wall of the casing or tubing while the lower slips grip it firmly. During retrieval, these components work together to ensure that the plug remains in place until it is removed.

BOY Bridge Plugs

BOY bridge plugs are designed for use in applications where extreme pressures and temperatures are present. These plugs feature a robust design that allows them to be set using either conventional coiled tubing or a wireline setting tool. The plug has an internal bypass valve that allows fluid to flow through the plug when needed, while preventing any unwanted leaks or seepage. It also features an integrated packing element, which creates a seal between the plug body and the surrounding casing or tubing.

Drilling & Milling Best Practice:

If the situation is to perform drilling or milling operations (junk mill), the recommended practice is as follows:

- Use a tricone Bit (IADC Bit Codes 2-1, 2-2, 2-3, 2-4, and 3-1) – medium hard formation. PDC Bit is not preferred.

- The best RPM shall be – 70 to 125

- Use a mud viscosity of 60 CPS for cuttings removal

- Weight on bit – Apply 5-7 Klbs. Until the top end of the mandrel is drilled away, which is 4-5 inches. Then increase 3 Klbs. of weight per inch of bit size to drill the remaining part. Example: 4-1/2 bit will use 9,000-13,500 lbs. of weight.

- Don’t apply weight over the recommended amount. Unreasonable weight can tear out chunks of the Bridge Plug, and performing another trip will be mandatory to remove the chunks to permit further penetration.

- Drill Collars – shall be used to supply the necessary WOB and Drilling bit stabilization. Example: 4-1/2 thru 5-1/2 (8 min.) 7 and larger (12 min.).

- Junk Baskets – One or more junk baskets shall be used in the drill string. If reverse circulation is planned, any tools in the tubing or drill string should have the same ID of the bit so cuttings will not bridge.

- Annular Velocity – 120 ft/min is to be considered.

- Junk basket above the bit.

Tools Required For Setting and Servicing

- Wireline Adapter Kit

- Stinger Seal Assembly

- Tubing Centralizer

- Mechanical Setting Tool

- Wireline Adapter Kit for Flapper Bottom

- Hydraulic Setting Tool

Bridge Plug Setting & Releasing Mechanisms

Indeed, the setting and retrieving mechanisms shall differ from manufacturer to manufacturer. But, we introduce a general procedure for you to get the idea.

Tension Set

- Run to the required depth while latched to its retrieving tool.

- Pick up, rotate XX (1/4) turn to the right at the plug, and lower the tubing to set lower slips.

- Pull sufficient tension to pack-off elements, slack off, and then pick up again to ensure plug setting (15,000 to 20,000 lbs).

- After setting the plug, slack off the tubing weight, hold the left-hand torque, and pick up to free the running tool from the plug.

Compression Set

- Run to the required depth while latched to the retrieving tool.

- Pick up, rotate XX (1/4) turn to the right at the plug, and lower the tubing to set lower slips.

- Slack off adequate weight to pack-off elements, then pick up to firmly set upper slips and slack off again (15,000 – 20,000 lbs).

- After setting the plug, slack off the tubing weight, hold the left-hand torque, and pick up to free the running tool from the plug.

Releasing Procedure

- Lower tubing until the retrieving tool tag on the bridge plug and latches on the same.

- Circulate to wash out the sand from the plug slips.

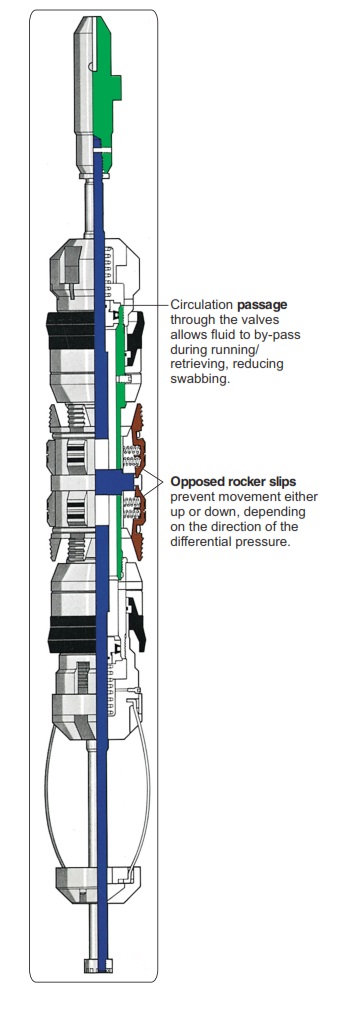

- Open the bypass valve by slacking off weight, hold right-hand torque, then pick up.

- Wait for pressure equalization.

- Pull upward to release the slips, relax packing elements, and re-latch.

- The plug may now be free to move.

- If the plug will not release conventionally, slack off, re-set, then pull up to shear J-pins and release the plug (J-pins will shear at 40,000 to 60,000 lbs each).

- Once you succeed in shearing the pins, the tool won’t be able to move downhole.

Important Features For Bridge Plug To Think About

- Many bridge plugs come with a large internal by-pass to minimize the swabbing effect of RIH & POOH. This bypass opens before releasing the plug to make a pressure equalization. Some BPs also have the ability to set and pack off the element in tension.

- The drillability of the tool also should be considered to save time and cost of the operations.

- Some tools come with the feature of converting to cement retainer or from mechanical set to wireline set.

- Good clearance between the bridge plug and casing must be considered also to have fast and safe running operations without sudden set.

- There are some designs that prevent movement due to opposed slips. This feature ensures that there will be no movement in case the differential pressure increased in and direction (upward or downward)

Conclusion

Bridge plugs are essential downhole tools used in oil and gas operations for pressure equalization, temporary abandonment, and zonal isolation. There are several types of bridge plugs available to suit a variety of applications. Each type has its own unique characteristics and benefits which make it suitable for certain types of operations. Using the right type of bridge plug can significantly reduce rig time and ensure successful pressure tests.