In 1932, the first bullet perforation gun was developed. This gun created a flow path from the formation into the casing by firing a projectile (bullet) through the cement and casing. It was known for providing a very uniform hole in the casing. However, as well depths required higher strength casing, it became less effective. The bullet also posed problems with plugging. Despite these limitations, the perforating gun is still in limited use today.

Working Principle

Bullet perforation guns may be fired selectively, one shot at a time. This will allow the gun to be moved between shots and allowing an unrestricted range of shot density. This facility may have limited specialized applications besides placing radioactive marker bullets. The diameters of these guns are comparable with medium-sized casing guns at 100-125 mm (4-5″).

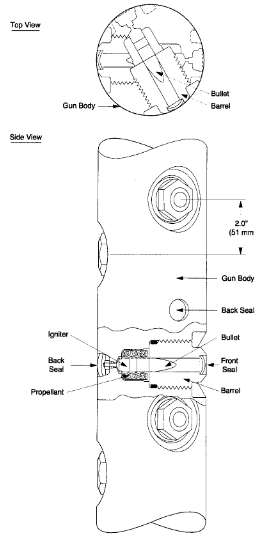

The options for phasing and gun size are limited compared with other perforation methods. It should be noted that the use of radioactive marker bullets will likely require the approval of the statutory authorities. In addition, adequate notice of their intended use should be given to the concerned service company. A schematic of a 100 mm (4″) bullet gun is shown in Fig. 1.

Recent laboratory tests of oil and gas companies compared the penetration depths of various bullets used to place radioactive markers for compaction monitoring. These tests indicated that the perforation bullet design would provide a better chance of remaining permanently in the borehole compared to SWS bullet designs

Bullet Perforation Disadvantages

One major problem with using bullet perforators to create perforation tunnels in wells is that the bullet or projectile can get lodged in the tunnel, which restricts the flow of reservoir fluid into the wellbore. Additionally, bullet perforators have a short penetration depth, typically only a few inches at best. As a result, they are not commonly used anymore, except when a uniform casing hole size is necessary for using ball sealers to divert acid.