In order to understand the strengths of casing tubular material, it is important to understand the basic terminology and process of manufacture such materials to be able of accomplishing a successful casing design.

Yield Strength In Casing Material

- Well Blowout

- Jar Intensifier

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

The strength is the material property of steel which is usually indicated by its minimum yield strength or ultimate tensile strength. Casing and tubing are manufactured mostly from ductile steel. Whereas brittle steels fracture without appreciable deformation, ductile steels can withstand significant plastic deformation prior to fracture.

Basic Stress-Strain Equations

Stress and strain are common terms used in describing strengths of casing materials.

If a tensile load (or force) is applied to a test sample cross-sectional area, then the tensile (or axial) stress is found by:

Stress = Force / Area

Axial strain is defined as the ratio of the test sample axial elongation to the original length of the sample:

Axial Strain = Axial Elongation / Original Length

Hooke’s Law defines stress as the product of the elastic constant or Young’s modulus of elasticity (E) and strain:

Stress = E x strain

Young’s Modulus for steel is typically 30 x 10^6 psi.

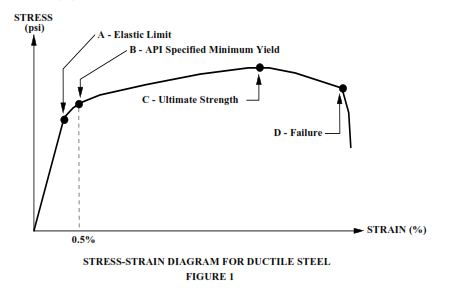

Figure 1 is a stress-strain diagram for a typical ductile steel.

- Point ‘A’ represents the yield strength or elastic limit of the steel. If the steel is stressed below the elastic limit, it will return to its original shape upon unstressing or unloading the test sample. Below the elastic limit, the stress-strain curve is linear.

- Point ‘B’ : The API specifies that the yield stress (yield strength) is the tensile stress required to produce a total elongation of 0.5% of the tensile test sample length. This is shown by point ‘B’ in the diagram. Stresses greater than the elastic limit cause permanent deformation of the steel and the steel will not return to its original shape when the load is taken away.

- Point ‘C’: If steel is stressed beyond its yield strength, it will deform plastically until its ultimate strength is reached as shown by point ‘C’. The ultimate strength is the maximum stress that the steel can sustain before it begins to fail. Beyond this point, the casing material will continue to deform plastically (with reducing stress) until complete failure (breakage) occurs as shown by point ‘D’.

The Hardness of Steel For Casing Material

Hardness is a casing material property that is the measure of a steel’s yield point in compression. When a material is required to resist wear, corrosion, erosion, or plastic deformation, it may be necessary to specify a specific hardness.

This material property generally increases with increasing material ultimate tensile strength. Very hard materials are brittle and will crack or fracture easily. Hardness is determined by a test where a load is applied with a small ball or pointed object.

The hardness property of the casing material is then expressed by the depth of the indentation caused by the pointed object. The “Rockwell C”, “Brinell”, or “Charpy” hardness scales are used to quantify the degree of hardness of an oilfield tubular casing material. Hardness can be expressed by a Charpy Impact Test, where a weighted pendulum is dropped onto a sample and the amount of impact it takes to break the sample is measured. This amount of impact must exceed a minimum standard. Mechanical properties of steel such as yield stress, ultimate tensile strength, ductility, or hardness can be achieved by

- Controlling the heat treating portion of the manufacturing process.

- Controlling the chemical composition of the steel.

Casing Material Heat Treating

Heat treating affects changes in the microstructure, or grain structure of the steel which directly affects its mechanical properties. Heat treating is an operation involving heating and/or cooling the solid steel tubular to develop the desired steel microstructures.

The five basic heat treatments are:

Quenched and Tempered

The steel is heated to 1500-1600 degree F. It is then rapidly quenched (or cooled) in water

or oil to produce a desired microstructure. It is then tempered (or re-heated) at 1000-1300 degree F to produce a desired combination of strength and ductility. This is the preferred method of producing high strength casing and tubing.

Normalizing

The steel is heated to 1600-1700 deg F and then cooled in air to produce a uniform microstructure and to alter mechanical properties.

Normalized and Tempered

The steel is first normalized (as above) and then tempered and air cooled. This tempering process slightly lowers the strength from the normalized condition but improves ductility and helps to relieve residual stresses.

Cold Drawn and Tempered

The tubing or casing is shaped or rolled to the desired OD at room temperature. This process causes a high residual stresses in the tube and increases the hardness due to plastic deformation. The tubular is then tempered to reform the microstructure from the cold drawn state. Tempering reduces the hardness and relieves the residual stresses.

Hot Rolled

The tubing or casing is shaped or rolled to the desired OD at a very high temperature. Hot rolling does not cause changes in the microstructure as in the cold rolling process above. Hot rolling produces a steel similar to the normalized condition.

Casing Material Chemical Composition

The chemical composition of steel directly affects all of its mechanical properties and corrosion resistance. Steels can be classified according to chemical composition as follows:

Carbon Steels

These steels are considered to be a mixture of iron and carbon with up to 2% carbon content. The high carbon steels contain up to 2% carbon, like casing material J-55, while the low carbon steels, like L-80, contain as low as 0.25% carbon. Carbon steels can contain other elements such as manganese or silicon in small quantities. Most tubulars are made of carbon steel.

Alloy Steels

These steels contain significant quantities of alloying elements other than carbon. A steel is considered an alloy steel when the content of either manganese, silicon or copper exceeds 1.65%, 0.6% and 0.6% respectively. A steel is also considered an alloy if there is a minimum content specified for aluminum, boron, cobalt, chromium, niobium, molybdenum, or nickel. Alloy steels are less susceptible to corrosion and more expensive than carbon steel.

High Alloy Steels

High-alloy steels contain more than 5% alloy elements, in particular, high concentrations of chromium, molybdenum, and nickel are used for high-alloy tubular casing material. High-alloy steels which contain greater than 12% chromium are often called “stainless” steels.

Low-Alloy Steels

Low-alloy steels contain less than 5% metallic alloying elements.