Cement Weighting Agents are used in certain cases as High pore pressures, Borehole instability, and deformable or plastic formations that shall be controlled by high hydrostatic pressures. Under such conditions, mud densities in excess of 18.0 lbm/gal [2.16 g/cm 3 ] are common. To maintain control of such wells, cement slurries of equal or greater density are also necessary.

One method of increasing the cement-slurry density (Check oil well cement properties) is simply to reduce the amount of mix water. To maintain pumpability, the addition of a dispersant is required. The principal disadvantage of reduced-water slurries is the difficulty of simultaneously achieving adequate fluid-loss control, acceptable slurry rheology, and no solids settling. Without excellent fluid-loss control, the risk of slurry bridging is higher. If solids settling occurs, the compressive strength and bonding will not be uniform across the cemented interval. The maximum slurry density attainable by reducing mix water is 18.0 lbm/gal [2.16 g/cm 3 ].

- Well Blowout

- Jar Intensifier

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

When higher slurry densities are required, materials with a high specific gravity are added. Such materials must meet several criteria to be acceptable as weighting agents.

- The particle-size distribution of the material must be compatible with the cement. Large particles tend to settle out of the slurry, while small particles tend to increase slurry viscosity.

- The mix water requirement must be low.

- The material must be inert with respect to cement hydration and compatible with other cement additives.

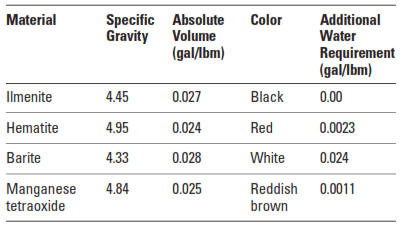

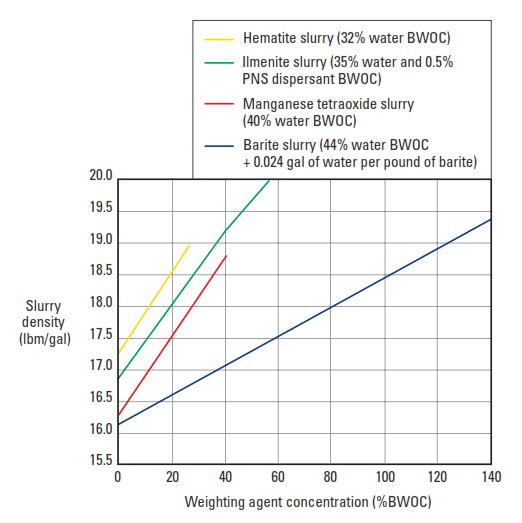

The most common weighting agents for cement slurries are ilmenite, hematite, barite, and manganese tetraoxide. A summary of their physical properties appears in Table 1. The concentrations of each material normally required to achieve a given slurry density are plotted in Fig. 1.

Cement Weighting Ilmenite

This Cement Weighting Agent (Ilmenite (FeTiO 3 )), a black granular material, has a specific gravity of 4.45. It has little effect on cement hydration. As currently supplied, the particle-size distribution of ilmenite is rather coarse; therefore, the slurry viscosity must be carefully adjusted to prevent sedimentation. Slurry densities in excess of 20.0 lbm/gal [2.4 g/cm 3 ] are easily attainable with ilmenite.

Hematite

With a specific gravity of 4.95, hematite (Fe2O3 ) is a very efficient weighting agent. The material occurs as red crystalline granules. Unlike ilmenite, it is currently supplied with a fine particle-size distribution. At high hematite concentrations, the addition of a dispersant is often necessary to prevent excessive slurry viscosity. Hematite is routinely used to prepare cement slurries with densities up to 19.0 lbm/gal [2.28 g/cm 3 ]; however, slurries with densities as high as 22 lbm/gal [2.64 g/cm 3 ] can be prepared.

Barite

Barite (BaSO4) as a cement weighting agent, a white powdery material, is readily available at most oilfield locations; however, it is not an efficient weighting agent compared to ilmenite, hematite, or manganese tetraoxide. Although it has a high specific gravity (4.33), additional water is required to wet its particles, which diminishes its effectiveness as a densifier. The additional water also decreases the compressive strength of the set cement. Nevertheless, slurries with densities up to 19.0 lbm/gal [2.28 g/cm 3 ] can be prepared with barite.

Cement Weighting Manganese tetraoxide

Manganese tetraoxide (Mn3O4 ), a reddish-brown powder, has a specific gravity of 4.84. It is available in both solid and liquid-slurry forms. The latter form is convenient for offshore applications. The particles are very small (average size 5 μm), resulting in a significantly greater particle surface area than other weighting agents. The tendency to settle is less than for hematite, and manganese tetraoxide can be added directly to the mix water (Johnston and Senese, 1992). This allows last-minute slurry density changes for primary cement jobs or emergency plugback jobs. Owing to its very high fineness, magnesium tetraoxide can sometimes shorten the thickening time of a slurry. Slurries with densities as high as 22 lbm/gal [2.64 g/cm 3 ] can be prepared when manganese tetraoxide is used in combination with hematite.

Ref: Schlumberger Well Cementing, Erik B. Nelson and Dominique Guillot