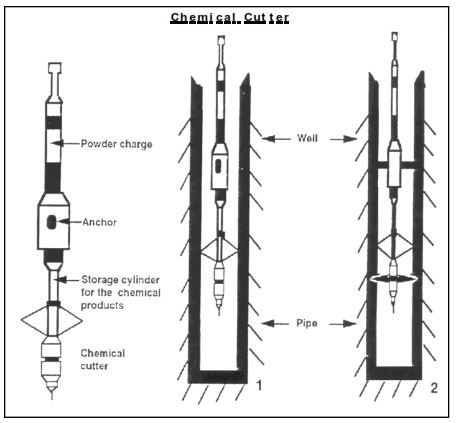

Chemical Cutter Wireline can be defined as an electric wireline tool and procedure that uses a propellant and a chemical, halogen fluoride, to burn a series of holes in the pipe, thereby weakening it so it is easily pulled apart (pipe recovery).

This method of cutting pipe is the most recent innovation. It was patented and, for years, was an exclusive process of one wireline company. Today, it is available through most electric wireline service companies for practically all sizes of tubing and drill pipe and the most popular sizes of the casing. All wireline cuts are generally economical because rig time is reduced to a minimum.

Pros

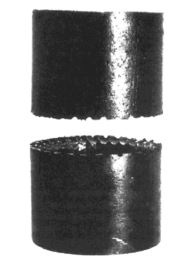

The big advantage of the chemical cutter wireline is that there is no flare, burr, or swelling of the pipe that is cut. Therefore, no dressing of the cut is necessary to catch it on the outside with an overshot or on the inside with a spear.

Chemical Cutter Wireline Components

The chemical cutting tool consists of a body having a series of chemical flow jets spaced around the lower part of the tool. The tool contains a propellant that forces the chemical reactant through the jets under high pressure and at high temperatures to react with the metal of the pipe.

Electric current ignites the propellant which forces the chemical, halogen fluoride or bromide trifluoride, through the reaction section which heats the chemical and forces it out the jets. The tool also contains pressure-actuated slips to prevent a vertical movement of the tool up the hole and ensure a successful cut.

The chemical cutting tool may also be explained as producing a series of perforations around the periphery of the pipe. The chemical reaction produces harmless salts that do not damage the adjacent casing. The chemical reaction products are harmless and rapidly dissipated in the well fluid.

The chemical cutter will not operate successfully in the dry pipe and requires at least one hundred feet of fluid above the tool when a cut is made. Since it is unnecessary to apply drilling torque to the pipe when chemically cutting compared to the string shot back-off, it is a safer process for rig personnel.