At specific points in the well, it is helpful to determine the overall trajectory (Check directional survey calculations excel sheet) in a single survey run (e.g., just before running casing). This is usually done by a Directional Magnetic Multi shot Survey Tool which takes a series of pictures. It also can be dropped from surface or run on W/L.

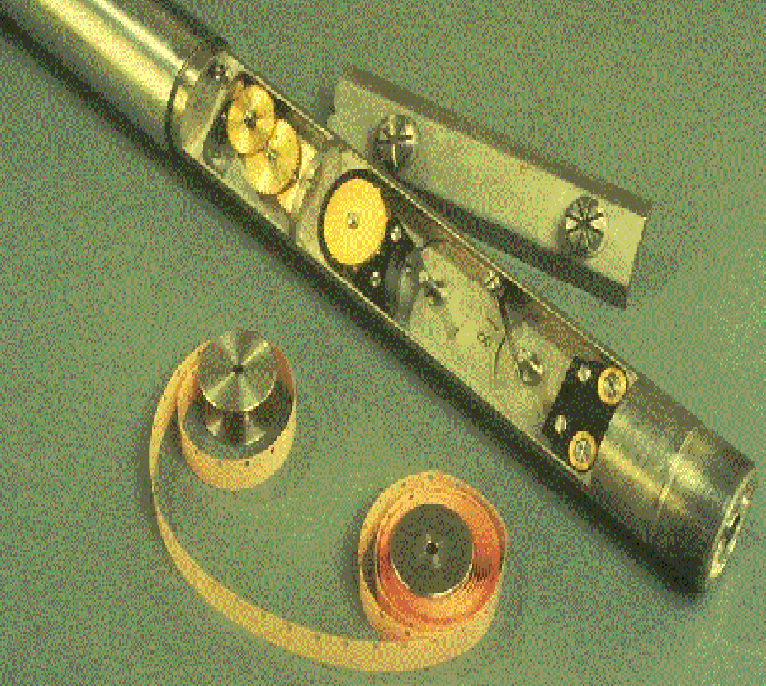

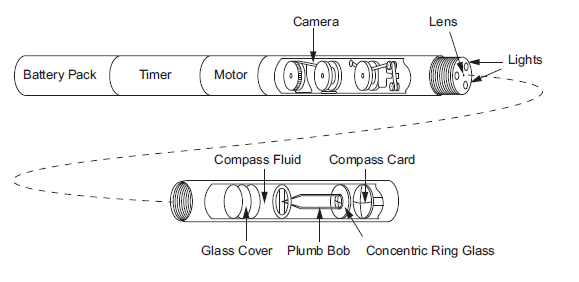

A magnetic multi-shot works on the same principle as a magnetic single shot, but has a particular camera unit. A roll of film is automatically exposed and wound on at pre-set intervals (Figure 1).

The magnetic multi-shot survey tool is either dropped free, or lowered into the non-magnetic collar by wireline.

Since the compass must remain within the non-magnetic collar to operate accurately, the multi-shot survey is taken as the pipe is tripped out of the hole. The directional surveyor must keep track of the depth at which the preset timer takes a picture.

Only those shots taken at a known depth when the pipe is stationary will be recorded. The film is developed when the multi-shot is recovered, and the survey results are read. The readings from a magnetic compass will be incorrect if the compass is close to a magnetized piece of steel.

Since both the drill string (Check: Drill String Major Components) and casing ( Check Casing Design Calculations Guide) will be magnetized, as they are run through the earth’s magnetic field, the magnetic surveying tools cannot be used unless some measure is taken to ensure that the well direction according to the earth’s magnetic field is accurately recorded on the compass.

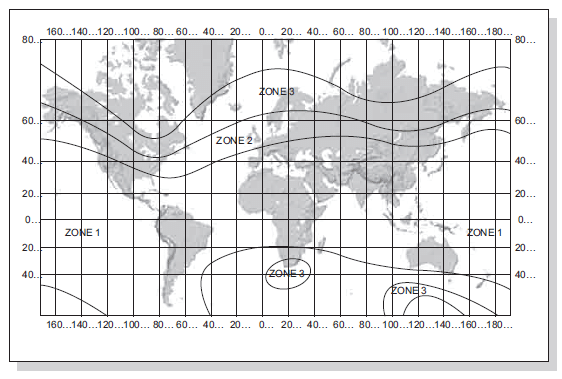

In the case of the drill string, this is done using non-magnetic drill collars in the BHA. These collars are made from Monel, and their presence undisturbed the Earth’s magnetic field. An accurate reading of the direction of the well can therefore be obtained. The number of Drill collars required depends on the magnetic latitude and hole direction.

The compass is measuring the horizontal component of the Earth’s magnetic field. Where the magnetic field lines are steeply dipping, and the hole direction is close to the East-West axis, the horizontal component is small, so more non-magnetic collars must be used (Figure 2). Since steel casing also becomes magnetized, this type of survey cannot be run in cased holes.

Running Procedures For Directional Magnetic Multi-Shot Survey Tool

- Check that the battery voltage and amperage conform to specifications.

- Load the battery pack.

- Connect the directional survey tool via the interface to the computer (or printer). Start the software program.

- Take readings of the directional survey tool in various orientations to verify the measurement of the gravity value. The stationary tool should correctly read inclination, high-side, and total gravitational values. The magnetic measurements and azimuth will be incorrect in a magnetically disturbed environment.

- Configure the probe via the software and set it up for either single-shot or multi-shot operation:

- set the time delay

- set the shot interval time.

- Ensure that the times are set so that the directional survey tool will commence recording shots at a time just before being run on wireline or dropped from the top of the drill pipe. If this leaves insufficient shots for the expected duration of the survey, then the delay time should be set to start the tool recording as it enters the NMDCs. Some contingency time should be included, determined by the running and retrieval mode.

- Check that the time delay and shot interval have been set correctly. If a tandem stack of probes is run, ensure that the timers are synchronized with the appropriate time delays.

- Start the probe and surface watch simultaneously before inserting the probe into the pressure barrel. Record the start time. The first shot will be taken when the time delay expires and the warm-up period has expired. Subsequent shots are then taken according to the shot timer interval (typically 10, 15, 20, or 30 seconds).

- The directional survey tool should have the correct running gear to ensure proper land-off and centralization in the NMDC. Non-magnetic centralizers are preferred to rubber fingers, which may collapse at inclinations over 15°.

- Run or drop the tool into the drillstring. Allow sufficient time for the directional survey tool to fall and land on the landing ring or mule shoe. In high-inclination holes, the tool can be pumped down carefully. Tools may suffer from impact damage, e.g., when the mud level is far below the rig floor or the tool is pumped down too fast. If the mud level is far below the rig floor, it is recommended that the tool is run on a wireline or the pipe is filled with mud.

- To ensure that the instruments traverse any restrictions in the string (e.g. jars etc.), the drill string should be rotated slowly (less than 10 RPM) while the instrument is dropping.

- Hold the drill string stationary long enough to take at least two shots per survey station when the instrument has landed on the landing ring.

- Take one rotational shot at the deepest survey station of a multi-shot survey. This procedure should be omitted if the process may endanger hole conditions or string integrity. Throughout the operation, the pumps should not be used.

- After the survey interval has been covered, trip out of the hole until the bit is in the casing shoe and recover the survey tool with a wireline overshot. Alternatively, the instrument can be recovered from the BHA at the surface.

- Remove the instrument from the pressure barrel. Check that the instrument is still working.

- Suppose a directional survey tool is to be run in single-shot mode by the Driller. In that case, the Wellsite Drilling Engineer is responsible for obtaining a detailed running procedure and equipment list from the Survey Company supplying the directional survey tool.