There are mainly two types of drill pipe connection threads, which are API Connection & Non-API Connection.

API Drill Pipe Connection Thread Types

Numbered Connections

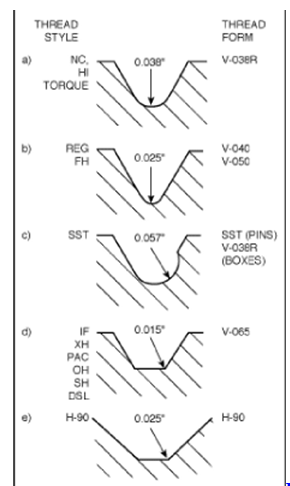

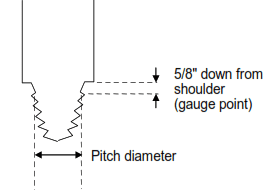

In 1968, API introduced ” NC ” connections to cover many needs, from macaroni tubing to 12-inch stiff drill collars. At the same time, API declared that the “IF” and “Full Hole” (FH) lines were obsolete. There are 17 NC connections with pitch diameters ranging from 1.1/16 (NC-10) to 7.3/4 inches (NC-77). NC means “Numbered Connection,” and the number signifies the connection’s Gauge Point Pitch Diameter (GPPD). For example,

- The NC-50 has a GPPD of 5.04170 inches,

- The NC-38 has a GPPD of 3.80800 inches, and so on.

Also, at the time, API took the most popular older connections, gave them a new drill pipe thread and name, and stuck them into the lineup. These included the following:

- NC 26 replaced 2 3/8″ IF NC 40 replaced 4″ FH

- NC 31 replaced 2 7/8″ IF NC 46 replaced 4 1/2″ XH

- NC 38 replaced 3 1/2″ IF NC 50 replaced 4 1/2″ IF

Regular Drill Pipe Connection Thread Type

“Regulars” remain the connections for BHA components, even though they are inferior to NCs of the same bending strength ratio because they have a sharper root radius. The reason for their popularity habit and the belief that changing to NC would cost more than it would be worth.

The number preceding “regular” in the name (for example, 6-5/8 Regular) refers to the pipe size on which the connection was originally to be (but is no longer) used.

Full Hole Connections

API made all Full-hole connections obsolete in 1968, to be superseded by NCs. However, the 5 1/2 FH was officially resurrected about ten years later. Also, the 6-5/8 FH was officially reinstated in 1993 because of its increasing popularity on 6-5/8 inch D/P.

Non-API Drill Pipe Connection Thread Types

However, here we shall mention only API drill pipe Specifications for thread types, but we will give you a simple introduction to other thread types.

H-90 Connections

H-90 thread forms are still common on BHA components. They were initially a Hughes Tool Company proprietary product and are easily recognized by their shallow 90-degree thread angle.

They are about equivalent in performance to Regulars, except that the shallow thread angle can cause high box hoop stress at high makeup torques. There is no apparent reason (except tradition) for their continued use since superior NCs exist for almost all applications.

PAC Connections

PAC connections are prevalent for 2-3/8 inch drill pipe and small diameter drill collars. They offer good clearance but often at the price of alarmingly low tensile and torsional capacity.

PACs are very poor selections for drill collars. Standard makeup torques in PAC drill collars cause pin-neck tensile stress of 87,500 psi, compared to 62,500 psi in a similar-sized NC connection. Since downhole stress can be additive to makeup stress, PAC connections are closer to failure even as they pass through the rotary.

PACs are also the only connections that still use the fatigue-prone V-065 thread form discarded by everyone else in 1968. However, this is not as bad as it seems since, in drill collars, PACs rarely survive tensile and torsional loads long enough to fail by fatigue anyway.

SST Connections

This is a patented design for tool joint pins. It is an NC pin with a rounded-out drill pipe thread flank that gives a root radius of 0.057 inches (compared to the NC’s 0.038 inches). SST boxes are identical to NC boxes of the same size. Tests by the developer show improved fatigue performance for SSTs. Ironically, SSTs are rarely found in BHA components where their larger thread root radius would be most beneficial.

Hi-Torque Connections

This is also a relatively new patented connection. It is simply an NC connection with an additional torque shoulder at the pin tip. This gives torsional capacities 40-60 percent higher than the original NC. This improvement is achieved at a higher cost, reduced availability, and sacrificed field repairability.