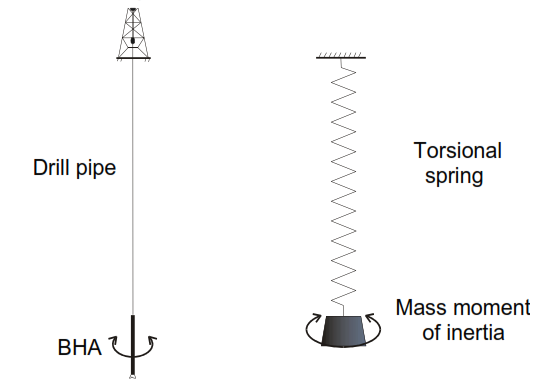

Stick-slip torsional drill string vibrations manifest in low-frequency torque fluctuations of significant amplitude during drilling or coring operations. It is often seen as a groaning noise emanating from the top drive or rotary table. The period of oscillation is typical of the order of 2-10 seconds. This period corresponds to the first eigenfrequency of the drill string/BHA combination, the so-called ‘torsional pendulum mode’. In this mode, the drill pipe behaves as a spring, and the BHA as rigid body inertia. This is depicted in Figure 4.

The period related to the drill string winding and unwinding is a function of the drill pipe’s length and diameter and the BHA’s inertia. Lighter BHAs and shorter drill pipe sections cause shorter periods.

Drilling Stick Slip Mechanism

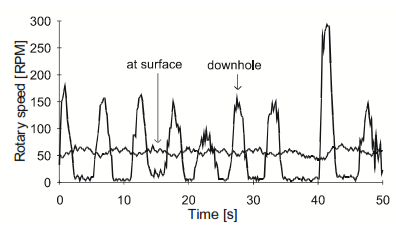

During a fully developed stick-slip, the drilling bit tends to come to a complete standstill periodically. Torque builds up and is then released, resulting in a rotational motion. Bit and BHA alternately rotate faster and slower than the drill pipe at the surface (see Figure ). If the difference between the static and dynamic friction coefficients is significant enough, the BHA can ‘over’ rotate and build up reverse torque, causing the bit/BHA to rotate backward. This can destroy the cutters on PDC bits.

Consequences Of Drilling Stick Slip

Stick-slip oscillations are especially damaging to the bit and drill string. Broken teeth and damaged PDC cutters are often the results of uneven loading at the bit/formation interface. Fatigue cracks in drill string components, as a result of torsional vibrations, are no exception and sometimes lead to drillstring twist-off. Moreover, stick-slip oscillations have been observed to occur during 50% of normal drilling time and lead to an average overall ROP reduction of 35 % for a wide range of bits and formations ].

Torsional Vibration Damping System

Systems to suppress torsional drillstring oscillations were developed during the late eighties by Rogaland Research (marketed by Hitec), Shell (KSEPL), and Sedco Forex. Most systems are based on the principle of drilling stick-slip or torsional vibration damping from the surface. This is realized as a hardware addition to the electric motor and a tuning procedure to achieve maximum damping.

Principle of operation

The hardware addition mentioned above is an electronic feedback loop that imposes a correction signal onto the drive’s speed input. This signal is derived from the torque demanded by the rotary table. The concept emerged from analyzing a mathematical model, which mimicked the interaction between BHA, drillstring, and rotary drive.

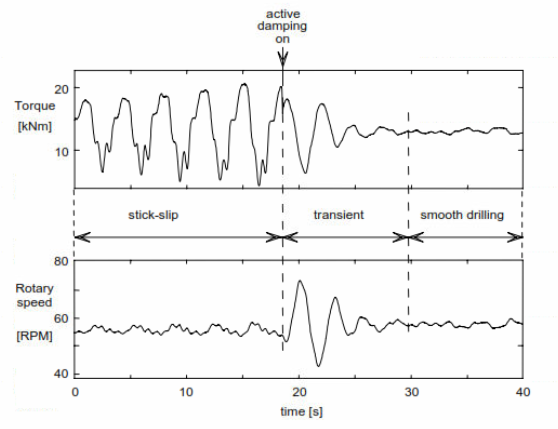

The effect of the feedback loop on the drive is equivalent to that of a spring with a parallel viscous damper attached at the drive side of the rotary table or top drive. The dimensioning of these two components depends on the geometry and material properties of the drill string. The effect of electronically mimicked damping is illustrated in the Figure below.

Upon activating the STRS, the rotary velocity undergoes a few hefty rotary speed cycles to absorb drilling stick-slip energy. The torque and the velocity decay to a low-level, noisy-type signal super-imposed on the static (nominal) level.

These systems include a controller that computes the proper parameters for the feedback system and subsequently adjusts the system automatically to these settings. Basic data relating to the drillstring, viz., diameters and lengths of the major components in the system, are entered via a keypad located in the doghouse.

Conclusion

Torsional vibrations are normally not seen from the rig floor since the rotary table drive tends to fix the vibrational angular motion at the surface. Still, however, under torsional vibration conditions, ample dynamic torque can be generated at the rotary table. The possible sources of torsional vibrations are time-varying axial forces and torsional loads, which can be applied to the drill collars from various sources such as pump pressure, side wall friction, drill bit/ formation interaction, and junk in the hole.