We will know from experience that the most challenging physical job on a drilling rig (also check: rig components) is when we are tripping pipe in and out of the hole. We will also know that we count the pipe in and we count the pipe out. The reason for counting the pipe is so the driller knows where the drilling bit & the BHA is in the well (BOP stack, Shoe, Etc.). The pipe count also checks that nothing untoward happens in the well during the trip. In the following sections, we will learn the components of the drilling trip sheet and the associated calculations with simple examples.

Displacement Volumes

We have already seen that mud will be displaced from the hole as we run a pipe into the hole. Furthermore, it will go to the trip tank, and as a result, the trip tank volume will go up.

The driller will calculate how much the volume should go up and will check this against how much the actual increase is.

The pipe displacement for a specific grade of 5″ drill pipe is 0.0076 bbl/ft, and the stand length is 93 ft. What volume of mud will one stand displace into the trip tank?

Volume (bbl) = Capacity Volume (bbl/ft) x Length (ft)

= 0.0076 x 93 = 0.71 bbl

In this example, the trip tank volume will increase by almost 3/4 of a barrel for every stand RIH. This increase could be tricky to check on a stand-by-stand basis, so the driller will usually monitor the displacement volume every five stands when tripping the drill pipe.

= 0.71 x 5 = 3.55 bbl

So, let’s calculate the displacement per stand for the heavy-weight drill pipe and Drill Collars below.

- HWDP Displacement – 0.0179 bbl/ft, stand length 92 ft

- Drill Collar Displacement – 0.0349 bbl/ft, stand length 88 ft

HWDP: = 0.0179 x 92 = 1.65 bbl

DC: = 0.0349 x 88 = 3.07 bbl

Displacement volume is usually monitored every stand for HWDP & Drill Collars due to the much larger volumes displaced per stand.

Trip Tank Volume

The driller will run the above calculations for the drill pipe, Heavy weight drill pipes & Drill Collars that RIH and record them on a drilling trip sheet. During pipe tripping, the driller will then observe the drilling fluids (also check: types of drilling fluids) volume increase into the trip tank – it should be the same as he has calculated. If there are any significant differences, We shall run an investigation as there could be a problem downhole, such as a well kicks or circulation losses.

The actual volume of mud the trip tank holds will depend on the type of rig we are working on but will be relatively small compared to our primary mud circulating system. The trip tank will fill up as we displace mud from the hole. It will be almost complete at some point, and we will need to transfer some to the active system. Therefore, we record such amounts on the drilling trip sheet so the count can continue accurately.

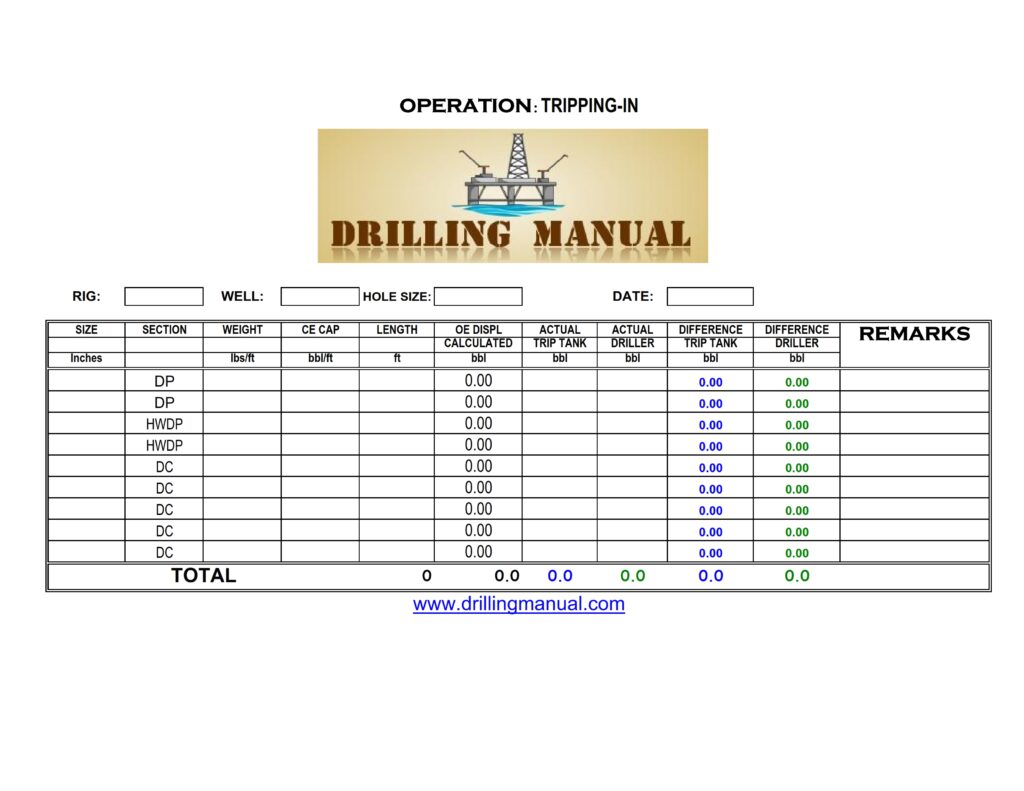

Trip Sheet Form

Trip sheets form may differ between oil and gas companies, but in the end, it will look like this:

| Stand No | Length Run/Pulled | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 0 | 0 | 0 | 0 | 4 | 0 | 0 | – |

| 5 | 467 | 467 | 4 | 9 | 4 | 4 | 0 |

| 10 | 467 | 934 | 4 | 13 | 4 | 8 | 0 |

| 15 | 463 | 1397 | 4 | 17 | 4 | 12 | 0 |

| 20 | 460 | 1857 | 4 | 21 | 4 | 16 | 0 |

In this example, note how the length per 5 stands and how we recorded the whole (or accumulated) length RIH. We calculate the total length by adding the length just to run to the previous tally.

Also, we recorded the actual displacement per 5 STDs and the total displacement. Drillers can calculate the actual displacement by subtracting the previous trip tank reading from the current one. Displacement is to one decimal place – as precise as we get on a trip tank. Also, we should investigate whether there is a difference between calculated and actual values.

If we had a 25-barrel trip tank, we would now need to consider transferring some mud to the active pit. So, we shall accurately count how much you transferred and record this as a note on the sheet.

| Stand No | Length Run/Pulled | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 0 | 0 | 0 | 0 | 5 | 0 | 0 | – |

| 5 | 465 | 465 | 3.5 | 8.5 | 3.5 | 3.5 | 0 |

| 10 | 465 | 930 | 3.5 | 12 | 3.5 | 7 | 0 |

| 15 | 460 | 1,390 | 3.5 | 15.5 | 3.5 | 10.5 | 0 |

| 20 | 463 | 1,853 | 3.5 | 19 | 3.5 | 14 | 0 |

| 15 bbl transferred to Active | – | – | – | 4 | – | 14 | 0 |

| 25 | 468 | 2,321 | 3.6 | 7.6 | 3.6 | 17.6 | 0 |

Example of Drilling Trip Sheet Calculations

RIH Trip Sheet

Now, let’s finalize the trip sheet for RIH with the below drill string. And assume that all actual displacements are as calculated.

- The trip tank holds 20 barrels.

- The trip tank start volume is 4 barrels.

- We should transfer drilling fluid out of the trip tank if we cannot displace the following amount into it—transfer 15 bbl out each time.

Drillers should monitor drill pipe displacement every five stands. Also, we recommend monitoring HWDP and drill collar displacement every STD.

Lengths

- Drill Collars:

- Stand 1 = 90ft;

- Stand 2 = 92ft;

- Stand 3 = 88ft

- HWDP:

- Stand 1 = 94ft;

- Stand 2 = 90ft;

- Stand 3 = 91ft

- Drill pipe Stands:

- 01-05 = 465ft;

- 06-10 = 466ft;

- 11-15 = 460ft;

- 16-20 = 462ft

- 21-25 = 467ft;

- 26-30 = 470ft;

- 31-35 = 466ft;

- 36-40 = 461ft

- 41-45 = 462ft;

- 46-50 = 452ft;

- 51-55 = 462ft;

Mud Loggers (Mud logger job description) always remember that drill collars go in first, HWDP, then drill pipe!

| Displacement Figures | Drill Pipe 0.0076 bbl/ft | HWDP 0.0179 bbl/ft | Drill Collars 0.0349 bbl/ft | ||||

| Stand No | Length Run/ | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

Calculated Sheet

| Displacement Figures | Drill Pipe 0.0076 bbl/ft | HWDP 0.0179 bbl/ft | Drill Collars 0.0349 bbl/ft | ||||

| Stand No | Length Run/ | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 0 | – | – | – | 4 | – | – | – |

| DC1 | 90 | 90 | 3.1 | 7.1 | 3.1 | 3.1 | 0 |

| DC2 | 92 | 182 | 3.2 | 10.3 | 3.2 | 6.3 | 0 |

| DC3 | 88 | 270 | 3.1 | 13.4 | 3.1 | 9.4 | 0 |

| HWDP1 | 94 | 364 | 1.7 | 15.1 | 1.7 | 11.1 | 0 |

| HWDP2 | 90 | 454 | 1.6 | 16.7 | 1.6 | 12.7 | 0 |

| HWDP3 | 91 | 545 | 1.6 | 18.3 | 1.6 | 14.3 | 0 |

15 bbl transferred to an active system

| Stand No | Length Run/ | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 5 | 465 | 1,010 | 3.5 | 6.8 | 3.5 | 17.8 | 0 |

| 10 | 466 | 1,476 | 3.5 | 10.3 | 3.5 | 21.3 | 0 |

| 15 | 460 | 1,936 | 3.5 | 13.8 | 3.5 | 24.8 | 0 |

| 20 | 462 | 2,398 | 3.5 | 17.3 | 3.5 | 28.3 | 0 |

15 bbl transferred to an active system

| Stand No | Length Run/Pulled | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 25 | 467 | 2,865 | 3.5 | 5.8 | 3.5 | 31.8 | 0 |

| 30 | 470 | 3,335 | 3.6 | 9.4 | 3.6 | 35.4 | 0 |

| 35 | 466 | 3,801 | 3.5 | 12.9 | 3.5 | 38.9 | 0 |

| 40 | 461 | 4,262 | 3.5 | 16.4 | 3.5 | 42.4 | 0 |

| 45 | 462 | 4,724 | 3.5 | 19.9 | 3.5 | 45.9 | 0 |

15 bbl transferred to an active system

| Stand No | Length Run/Pulled | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| 50 | 452 | 5,176 | 3.4 | 8.3 | 3.4 | 49.3 | 0 |

| 55 | 462 | 5,638 | 3.5 | 11.8 | 3.5 | 52.8 | 0 |

As we trip into the hole, mud moves out, and drillers must monitor to ensure they are displacing the correct amount.

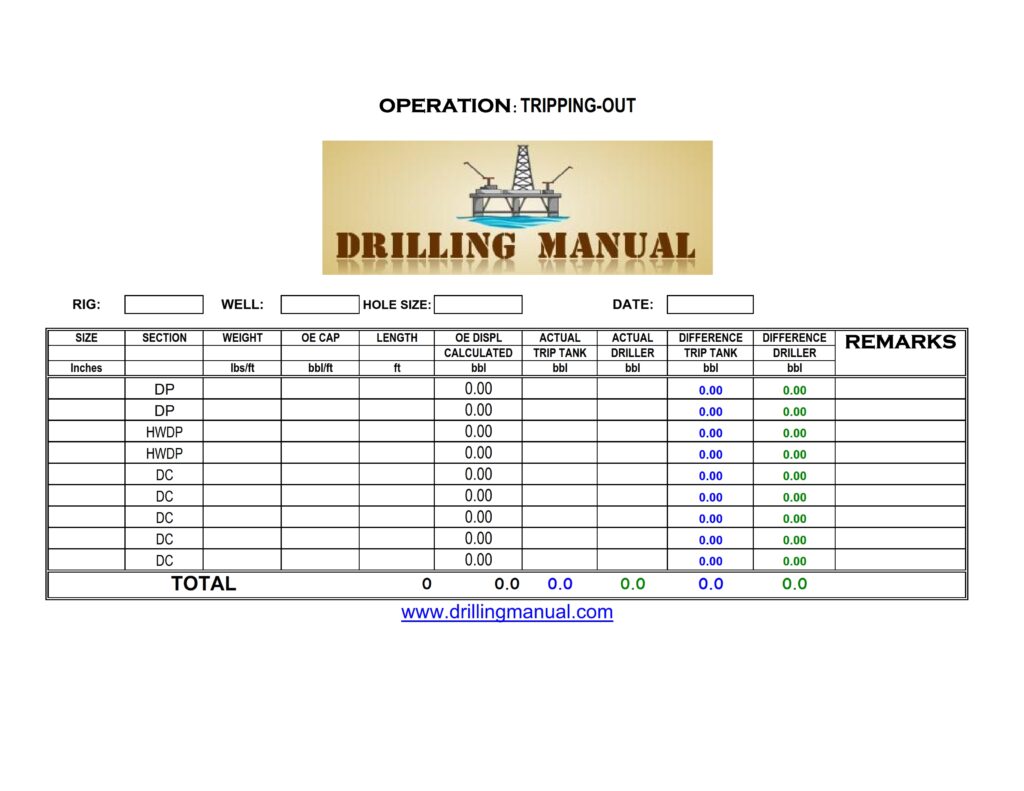

POOH Trip Sheet In Drilling

As we pull the pipe out of the hole, the mud level will drop as we remove the pipe. One rule of thumb for well control is to keep the hole full by circulating the trip tank across the top of the hole. Therefore, circulating the drilling fluid from the trip tank across the top of the hole and back into the trip tank, thus ensuring the hole is always full.

As we trip out the drill string from the hole, we remove a volume from the hole capacity, allowing the mud to replace this volume from the trip tank. This action means that the trip tank volume will decrease. The driller will keep observing the level drop in the trip tank to confirm it is as calculated. As a result, the driller will keep transferring mud into the trip tank as the tank’s level drops.

Complete the trip sheet below for a POOH with a drill string. Assume we transfer 15 bbl when the level of the trip tank drops below 5 bbl. Monitor as before – trip in the order shown.

- DP 1-5 = 465ft;

- DP 6-10 = 466ft;

- HWDP1 = 94ft;

- HWDP2 = 90ft;

- DC1 = 90ft;

- DC2 = 88ft;

- DC3 = 89ft

| Displacement Figures | Drill Pipe 0.0076 bbl/ft | HWDP 0.0179 bbl/ft | Drill Collars 0.0349 bbl/ft | ||||

| Stand No | Length | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| – | – | – | – | 10 | – | – | – |

Answer

| Displacement Figures | Drill Pipe 0.0076 bbl/ft | HWDP 0.0179 bbl/ft | Drill Collars 0.0349 bbl/ft | ||||

| Stand No | Length | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| – | – | – | – | 10 | – | – | – |

| DP5 | 465 | 465 | 3.5 | 6.5 | 3.5 | 3.5 | 0 |

| DP10 | 466 | 931 | 3.5 | 3 | 3.5 | 7 | 0 |

15 bbl transferred from active

| Stand No | Length | Total Length | Calculated Displacement | Trip Tank Volume | Actual Displacement | Total Displacement | Difference |

| HWDP1 | 94 | 1,025 | 1.7 | 16.3 | 1.7 | 8.7 | 0 |

| HWDP2 | 90 | 1,115 | 1.6 | 14.7 | 1.6 | 10.3 | 0 |

| DC1 | 90 | 1,205 | 3.1 | 11.6 | 3.1 | 13.4 | 0 |

| DC2 | 88 | 1,293 | 3.1 | 8.5 | 3.1 | 16.5 | 0 |

| DC3 | 89 | 1,382 | 3.1 | 5.4 | 3.1 | 19.6 | 0 |

Accurate volume monitoring when RIH or POOH is one of the key responsibilities of the driller. The calculations involved are not difficult to do, but accuracy and neatness are important.