Unexplained changes in the readings on the Flow Show and PVT recorders should be investigated promptly. This usually takes the form of a flow check. In other words, They are implemented to guarantee that the well is stable. it should be carried out with the mud pumps off to check the well with Drilling ECD effects removed. They are also regularly done when there is a need for tripping pipe at the following minimum places:

- on bottom

- at the casing shoe

- before the BHA is pulled into the BOP Stack‘s

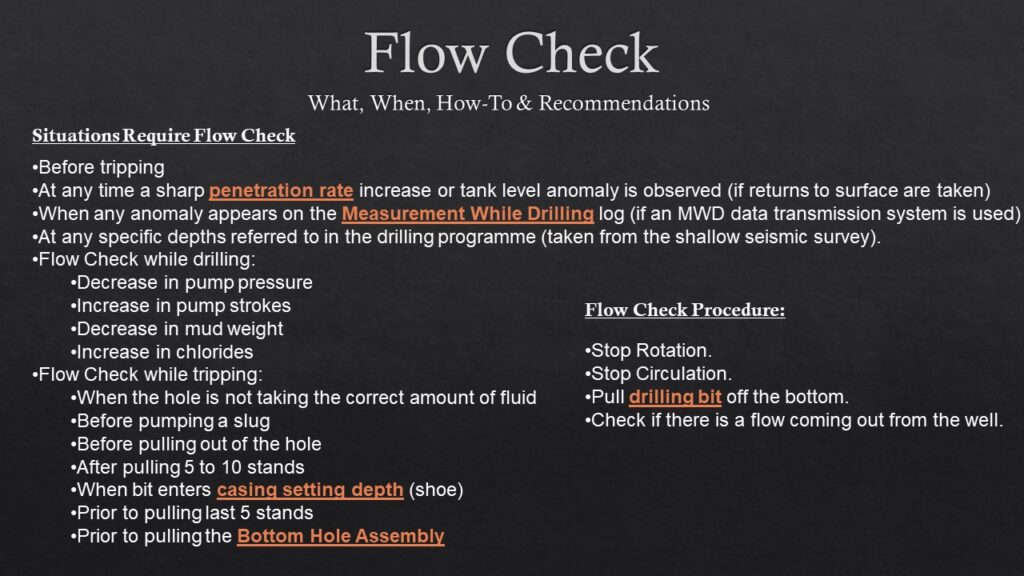

Flow Check Procedure:

The procedure is simply the following:

- Stop Rotation.

- Stop Circulation.

- Pull drilling bit off the bottom.

- Check if there is a return coming out from the well.

If the flow continues after the circulation has been stopped then Secondary Pressure Control measures are initiated. Sometimes flow check may be replaced by shutting in the well immediately, particularly where kick tolerance (the maximum size of influx that can be safely circulated out without breaking down the previous casing shoe) is low, or the PVT or Flowshow indications are dramatic.

In Floating Rigs, It may be difficult to obtain an accurate flow check by observing the flowline on the rig floor or flowline at the shaker due to rig movement. To obtain an accurate check:

- Stop rotating, pick up and space out for hang-off BOP rams.

- Shut down rig pumps.

- Line up drilling trip tank.

- Close the shaker valve.

- Half fill the trip tank with mud and check for a return.

The duration of the flow check depends on several factors and should be defined locally. Following a negative check (no return observed), normal drilling may be resumed. If it is not conclusive, the hole should be circulated bottom up before deciding to drill ahead.

All flow checks shall be at least 15 minutes.

Aramco Manual For Well Control

Situations Require Flow Checks

It should be made as a minimum, before pulling out, in the last casing shoe, and before starting to pull the drill collars. For exploration wells, it is recommended to make a short check trip prior to pulling out completely to verify that the overbalance is sufficient to prevent swabbing the well. After the check trip – of perhaps ten stands – the well is circulated “bottoms-up” to check for gas cut drilling fluid or other signs of near balance.

In general, flow checks should be made in the following situations:

- Before tripping

- At any time a sharp penetration rate increase or tank level anomaly is observed (if returns to the surface are taken)

- When any anomaly appears on the Measurement While Drilling log (if an MWD data transmission system is used)

- At any specific depths referred to in the drilling program (taken from the shallow seismic survey).

- While drilling:

- Decrease in pump pressure

- Increase in pump strokes

- Decrease in mud weight

- Increase in chlorides

- Flow Check while tripping:

- When the hole is not taking the correct amount of fluid

- Before pumping a slug

- Before pulling out of the hole

- After pulling 5 to 10 stands

- When bit enters casing setting depth (shoe)

- Prior to pulling last 5 stands

- Prior to pulling the Bottom Hole Assembly

When There Are A Swabbing

If swabbing has been detected and the well is not flowing a non-return valve should be installed and the drilling bit returned to the bottom. Flow check each stand.

Improper Hole Fill While Drilling

Flow into the wellbore while drilling will cause improper hole fill-up, if this is detected a flow check should be done.

Increase In Penetration Rate

A gradual or sudden increase in penetration rate (although this may be due to various factors, it could indicate that an overpressured formation has been penetrated. When a drilling break occurs, a flow check should be made as quickly as possible)

A drilling break is a distinct change in penetration rate which does not always appear as a sharp change but may be a gradual increase over a fairly long interval. A decrease in penetration rate can also be seen as a drilling break, depending on the type of formation which is being drilled ( e.g. drilling from salt into carbonate). When a drilling break is encountered, a flow check should be made to confirm that formation fluids are not entering the wellbore.

Entering Reservoir Formations During Fast Drilling

During fast drilling, the effective density of the drilling fluid in the annulus may increase considerably due to being heavily loaded with cuttings. Drilling with such heavier drilling fluid returns could wrap an indication of entering a more highly pressured formation. Primary well control will then only be lost and an influx will only occur while circulating the hole clean. If it is seen from the cuttings that a reservoir formation has been penetrated during a period of fast drilling then the situation should be checked by circulating bottoms up from time to time and making flow checks as the clean, lighter, mud rises in the annulus.

While Tripping

Except for specific reasons (e.g. when retrieving long and tight formation cores), circulation should preferably not be carried out at intermediate stages when tripping drill pipe or running casing into the hole. A flow check is preferred.

Surface Shallow Gas Areas

It is recommended to flow check each connection while drilling the pilot hole in potential shallow gas areas. Measuring drilling fluid density in and out, and checking for seepage mud losses are all important practices that must be applied continuously.

Flow Check Recommendations

Rig movement with a floating drilling rig makes it more difficult to recognize kick indicators while drilling or tripping. For this reason, additional fluid volume detection equipment is installed in the mud pits to compensate for rig motion. It is recommended for floating drilling units that flow checks be performed on the trip tank with the hole fill pump circulating across the bell nipple to eliminate rig motion as much as possible.

When any positive indication of a kick is observed such as a sudden increase in return or an increase in pit level, then the well should be shut in immediately without doing a check for return. If the increase in return or pit gain is hard to detect when a flow check can be done to confirm the well is flowing.

References:

- Shell Well Control – Principles & Practices Manual

- Well Control For Rig Site Drilling Team