A hydraulic Jar is one of the drilling jar types used in drilling operations to free stuck pipe problems. This article will introduce the hydraulic drilling jar operation and mechanism. We also recommend visiting Drilling Jar Placement, Types, and Calculations. Operation & working principle article

Hydraulic Drilling Jar Mechanism

The tripping (check also: Tripping pipe procedures) action of a hydraulic jar depends on energy stored in the stretch of the string. When an overpull is applied, the stored energy is released, and the jar fires.

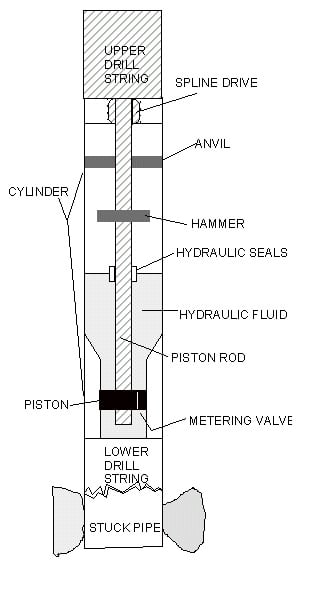

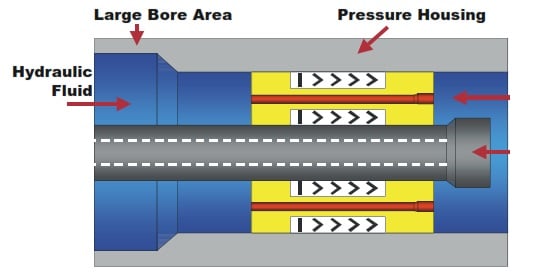

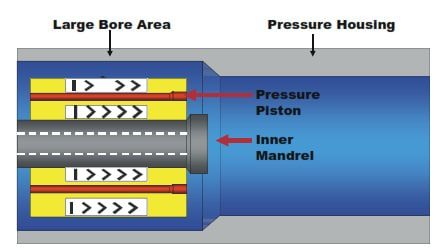

A fluid metering system is used to delay the tripping of the hydraulic jar. As overpull is applied to the work string, the string is stretched. The hydraulic fluid in the jar chamber is forced through a series of small jets (Figure 1), slowing the upward movement of the inner mandrel. The mandrel then reaches an enlarged ID area, dumping the fluid rapidly to the other side. This hydraulic pressure release allows the jar to fire, delivering a high-impact blow to the fish (Figure 2).

Hydraulic jar blow intensity is determined by the magnitude of the pull or push on the string. No torque or other manipulation of the string is required. The jar trigger setting is directly proportional to the amount of overpull or set down weight applied.

As mentioned above, with all hydraulic jars, there is a waiting time between cocking and tripping ranging from 1½ to 2 minutes. This time usually shortens after they heat up. However, hydraulic jars can generate heat buildup, which, if unchecked, can affect performance. Therefore, jars that have some form of heat compensation are better suited to prolonged jarring. Pumps used with this type of jar increase the upward hitting force and decrease the downward hitting force. Hydraulic jars are more versatile than mechanical jars – allowing full downhole adjustment.

Hydraulic Jar Operation

The following is a simplified description of how an up jar functions:

- As overpull is applied, the piston rod, which is attached to the top side of the drill string, is pulled through a cylinder connected to the downhole side of the drill string.

- The piston on the rod acts as a hydraulic damper, with a small amount of fluid allowed to leak through the metering valve.

- However, when the piston reaches the increased area of the cylinder, all the hydraulic pressure is suddenly released. Then, with the damping effect gone, the piston flies forward unrestricted, allowing the hammer to strike the anvil.

- To reset, overpull is released, and the weight of the drill string above the jar forces the piston back into the cylinder.

Advantages

- Impact force is variable and is determined by the overpull or set down weight.

- Not affected by torque.

- Circulation enhances impact force.

Disadvantages

- The hydraulic drilling jar is inoperable after a seal failure.

- Performance can be affected by overheating.

- Recommended overpull can be exceeded.

- Longer cycling times.

- Jar can be cocked inadvertently. Surface precautions are required.

- The time delay can result in loss of energy.

Dailey Hydraulic Jar

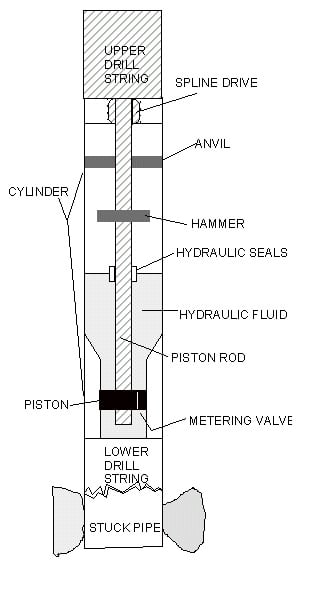

The Dailey hydraulic jar (Figure 4) consists of an inner and outer mandrel. The inner mandrel has two pistons that seal on the outer mandrel. Between the two pistons is a hydraulic valve that is closed when the jar is cocked and in its central position.

The Dailey Hydraulic Applications:

- In vertical, directional, and extended reach wells with elevated torque and

drag - As the lower tool when running tandem jars

- In any case, with limited over-pull capacity.

Advantages Of The Dailey Jar:

- Hydraulic time delay with a mechanical triggering device

- Straight push/pull operation

- Variable tripping loads

- Consistent time delay

- No bleed-off

- Protected seals and impact shoulders

- Increased over-pull limits.

Dailey Jar Operations:

- Close the jar mandrel and mark the pipe for reference.

- Pick up 20,000 lbs. of overpull and let the jars bleed open.

- Take a significant overpull and mark the pipe for reference.

- Close the jar mandrel again (the previous mark should be at the rotary).

- Pull up approximately one-half of the jar manufacturer’s maximum jarring load and wait for the jar to fire.

- Slack off slowly to start cocking the jars. Note: Slacking off slowly saves the seal integrity.

- Check to see if any progress has been made by the position of the referenced mark on the pipe.

- Continue jarring while raising the overpull in 10,000 lb. increments every 10 minutes until the maximum jarring load is reached.

- Continue jarring at the maximum jar capacity until the fish is freed, the jar wears out, or a decision is made to do something else because of a lack of progress.