The alertness in determining Kick early warning signs in well control is of the uppermost importance to wellbore safety. Careful observance and positive reaction to these signs will keep the well under control and prevent the occurrence of a good flow situation. This article will also discuss the positive indicators for oil well kicks.

The major kick warning signs include the following:

- Kick Early Warning Signs

- Drilling Break ( Increase in drilling penetration rate)

- Increase in drilling torque & drag.

- Decrease in shale density

- Increase in cutting size and shape

- Mud properties changes

- Increase in trip, connection & background gases

- Change in temperature of the return drilling mud

- Decrease in d-exponent

- Kick Positive Indicators

- The gain in mud pit level

- Increase in the return mud flow rate

- The well is flowing while the pumps are off.

- Improper hole fill-up.

The various signs that have been recorded as kick-early warning indicators are not consistent in all situations. The signs, however, may have to be used collectively as one indicator may not accurately provide the warning of getting into an unbalanced situation. Even though the series of signs may change between wells, early warning indications can be found in the following list.

Kick Early Warning Signs

Why do we consider a drilling break as An early warning sign?

When drilling ahead and using consistent drilling parameters, as the bit wears, a normal trend of decreased penetration rate (Check the factors that affect drilling penetration rate) should occur. Suppose the differential pressure between the hydrostatic pressure of the drilling fluid and formation pore pressure decreases. In that case, the drilling rate increases as the chip hold-down effect is reduced.

A general and consistent increase in penetration rate is often a fairly good indicator that a transition zone may have been penetrated. A rapid increase in penetration rate may indicate that an abnormal pressure formation has entered and an under-balance situation has occurred.

Increased Torque & Drag

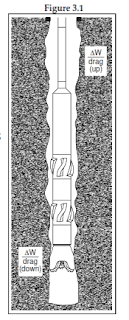

Increased drilling torque and drag are often noted when drilling into overpressured shale formations due to the underbalanced mud density‘s inability to hold back the formation’s physical encroachment into the wellbore. Drag and rotating torque are both indirect and qualitative indicators of overpressure. They are also indicators of borehole instability problems and other mechanical problems. Torque and drag trend increases often indicate to the driller that a transition zone has been drilled, and it may be considered an early kick warning sign. Each connection should record up and down drag and average torque figures. These trends are valuable when comparing other trend changes.

How can a decrease in shale density Be one of the kick warning signs?

The density of shale normally increases with depth but decreases as abnormal pressure zones are drilled. The density of the cuttings can be determined at the surface and plotted against depth. A normal trend line will be established, and deviations can indicate changes in pore pressure.

Increase In Cutting Size and shape

In transition zones or in abnormally pressured shales (sandy shales and bedding sand streaks) the shales break off and fall into hole because of underbalanced conditions (pore pressure greater than mud hydrostatic pressure). Water wetting may further aggravate this problem.

Changes in the Shape of Shale Cuttings can occur as an underbalanced situation develops (check also underbalanced drilling). The particles are often larger and may be sharp and angular in the transition zone. Extra fill on the bottom may coincide with the trend change. Severe sloughing will often cause changes in pressure and stroke relationship.

Normally, high-pressure shales produce small cuttings with rounded edges and are generally flat, while cuttings from an overpressured shale are often long and splintery with angular edges. As a reduction of the hydrostatic differential between the pore pressure and bottom hole pressure occurs, the hole cuttings will have a greater tendency to come off the bottom. This can also lead to shale expansion, causing cracking and sloughing of the shales into the wellbore. Changes in cutting shape and cutting load over the shale shakers need monitoring at the surface as it is one of the major early warning signs of kick.

Changes In Mud Properties

Water-cut mud, or a chloride (and sometimes calcium) increase circulated from the bottom, indicates that formation fluid has entered the wellbore. It could be created by swabbing or indicate a well flow is underway. A small increase of chlorides in drilling mud or calcium increases could indicate tight (non-permeable) zones with high pressure.

In certain types of mud, the viscosity will increase when saltwater enters the wellbore and is mixed with the mud. This is called flocculation because the little molecules of mud solids, which are normally dispersed, form a little “group” called flocs. These flocs cause viscosity and gel increases.

In other drilling fluids types, you might see a viscosity decrease caused by water cutting (weight decrease). This is true when operating with low-pH salt-saturated water-based drilling muds.

In oil-based muds, any water contamination would act as a “solid” and cause viscosity to increase. Gas-cut mud would be fluffy and would have higher viscosities (and lower mud weight).

It Is Essential To Know That Trend Changes Are More Important Than Actual Value Of The Change As A Warning Sign For Oil Well Kicks.

Increase In Trip, Connection, and Background Gas.

It is necessary to monitor return mud for contamination with formation fluids. Doing this will be done by constantly recording the flowline mud density and accurately monitoring gas levels in the returned mud.

Gas-cut mud does not in itself indicate that the well is flowing (gas may be entrained in the cuttings). However, we must treat it as an early warning sign of a possible kick. Therefore, closely monitoring pit levels is necessary if significant gas levels are detected in the mud.

An essential part of interpreting the gas level in the mud is understanding the conditions in which the gas entered the mud in the first place. In general, gas can enter the mud for one or more of the following reasons:

- Drilling a formation that contains gas even with a suitable overbalance.

- Temporary reduction in hydrostatic pressure results from swabbing as pipe moved in the hole.

- Pore pressure in a formation is greater than the hydrostatic pressure of the mud column.

Gas due to one or a combination of the above, can be classified as one of the following groups:

Drilled Gas

When porous formations containing gas are drilled, a certain quantity of the gas contained in the cuttings will enter the mud. Gas that enters the mud, unless in solution with oil base mud and kept at a pressure higher than its bubble point, will expand as it is circulated up the hole, causing gas cutting at the flowline. Gas cutting due to this mechanism will occur even if the formation is overbalanced. Raising the mud weight will not prevent it.

Note that drilled gas will only be evident when it takes to circulate the cuttings from the porous formation.

Connection Gas

Measuring Connection gases at the surface as a distinct increase above background gas as bottoms-up occurs after a connection. They result in a temporary reduction in the effective total pressure of the mud column during a connection. This is due to the pump shut down and the swabbing action of the drill pipe (API Drill Pipe Specifications) .

In all cases, connection gases indicate a condition of near balance. When an increased trend of connection gases is identified, consideration should be given to weighting up the mud before drilling operations continue, and particularly before any tripping operations.

Trip Gas

Trip gas is any gas that enters the mud while tripping the pipe with the hole appearing static. Detecting trip gas will occur when circulating bottoms up after a round trip. If the static mud column is sufficient to balance the formation pressure, the trip gas will result from swabbing and gas diffusion.

Significant trip gas may indicate that a close to balance situation exists in the hole.

Gas Due to Inadequate Mud Density

The surface indication of an underbalanced formation depends on the degree of under balance and the formation permeability. Drilling of a permeable formation that is significantly overbalanced will cause an immediate flow increase followed by a pit gain.

Change In The Temperature Of The Return Drilling Mud

The temperature will normally take a sharp increase in transition zones. The circulating rate, elapsed time since tripping, and mud volume will influence flowline temperature trends.

The temperature gradient in abnormally pressured formations is generally higher than normal. The temperature gradient decreases before penetrating the interface and, therefore, marked differences can give an early indication of abnormal pressures. This is usually a surface measurement that tends to be influenced by operating factors.

Decrease In D-Exponent

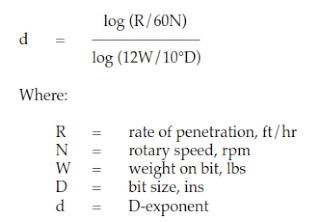

Plotting the D-Exponent will be by the well loggers and always maintained current. This value was introduced in the mid-sixties to calculate a normalized penetration rate concerning certain drilling parameters.

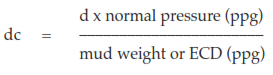

The D-exponent may need correction and normalization for mud weight changes and/ or ECD (equivalent circulating density) by the following:

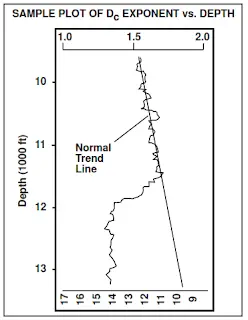

A plot of Dc-Exponent versus depth in shale sections was used with moderate success in predicting abnormal pressure. Trends of the Dc-exponent normally increase with depth, but in transition zones, its value decreases to lower-than-expected values.

Mud logging companies have further variations/models that try to normalize for other parameters (such as bit wear and rock strength) to varying degrees of success. An illustration of a DC plot is in Figure 3.

Positive Kick Indicators

A Kick in drilling occurs when the hydrostatic pressure of the mud column in the well is less than the formation pressure provided that the formation has the ability to produce. A Kick is a positive indicator that formation fluid is entering the wellbore, and Secondary Well Control must be initiated.

Positive Warning Sign For Well Kicks While Drilling

- Flow into the wellbore causes two changes to occur in the mud circulating system:

- Increase of active mud system volume.” gain in pit level”:

The gain in the pit level detected by pit level measuring instruments with the recorder mounted at the driller’s console and supported by the mudlogger

Good communication between crew members is essential on the rig as it will detect any warning signs for a well kick. Drillers should ensure crew hands notify them if they do anything to change the level in the pits. If crew hands add volume to the pits, they should also notify the driller when they stop.

- The mud return flow rate exceeds the mud flow rate into the well. “flow monitoring system.”

- When drilling a formation containing gas, a minor rise in pit level will be noted because of the core volume of gas being drilled. However, this will occur only as the gas nears the surface, and is due to the drilled gas expanding and is not necessarily an indication that the well got under balance.

- The timing of the increase in pit volume is important in distinguishing between a true Kick and gas expansion only. The hole will also take the same volume of fluid it gave up after the gas bubble reaches the surface. However, if there is any question about the cause of the pit gain, stop the pump and check the well for flow.

- On trips, the drill crew should be able to recognize a 5-barrel Kick or less. During drilling, the crews can generally recognize a 10-barrel Kick or less.

5- The size or severity of a Kick depends on the volume of foreign fluid allowed to enter the wellbore, which depends on

- The degree of underbalance.

- The formation permeability.

- The length of time it takes the drilling crew to detect that the well is kicking.

Improper Hole Fill Up | Recognizing a Kick While Tripping

Flow into the wellbore will cause improper hole fill-up; if this is seen, a flow check should be performed.

- If the flow check is positive then the well should be shut-in.

- If the flow check is negative, the drill string should be run back to the bottom to circulate the bottoms up (stripping operation may have to be used here).

Trip tanks

- Trip Tanks are the safest and most reliable method of monitoring mud volumes on trips. It is recommended that a continuous hole fill-up be used when tripping out of the hole. When tripping in the hole, the trip tank should be used to ensure the correct mud displacement.

- Rig movement with a floating drilling rig makes it more difficult to recognize Kick warning signs while drilling or tripping in with Bottom Hole Assembly BHA. For this reason, additional fluid volume detection equipment is installed in the mud pits to compensate for rig motion. It is necessary for floating drilling units that perform flow checks on the trip tank with the hole fill pump circulating across the bell nipple to eliminate rig motion as much as possible.

Situations That Can Mask A Kick

- Mud weight adjustments while drilling.

- Mud transfers while drilling.

- Partially lost circulation.

- Solids control equipment and degassing mud.

- Spills and leaks in surface equipment.

- Drain back.

- Pump start-up and shut down.

Good Kick Warning Signs Resources:

Related Good Papers: Early detection enhancement of the kick and near-balance drilling using mud logging warning sign

Ref: Saudi Aramco Well Control Manual 2006 – (Saudi Arabia Oil History)