Mud balance is one of the devices used for measuring the density of a Water-Based Mud, Oil Based Mud or completion / work-over fluids. In this article, we will handle the good practice of the mud balance test procedure.

Mud Balance

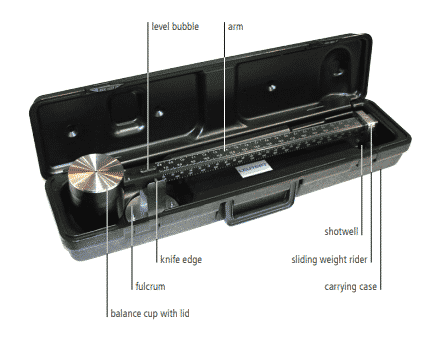

Mud Balance Equipment

- Mud balance

- 1-qt (946 cm) graduated mud cup

- Thermometer: 32 to 220°F (0 to 104°C)

Mud Balance Test Procedure

- Well Blowout

- Jar Intensifier

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

- Place the base stand or carrying case on a flat, level surface.

- Collect a fluid sample.

- Measure and record the temperature of the sample; transfer the sample to the mud balance cup.

- Tap the side of the mud balance cup gently with the cup’s lid to break out any trapped air or gas.

Note: If trapped air or gas is present, use the pressurized fluid density balance to determine mud weight. The procedure for using the pressurized fluid density balance follows this procedure. - Place the lid on the mud balance cup with a twisting motion and make sure some of the test sample is expelled through the lid’s vent hole.

Note: Immersing the lid in the fluid sample helps ensure a better closing. - Seal the vent hole with a finger and clean the balance with water, base oil, or solvent. Wipe off any excess water, base oil, or solvent.

- Fit the knife edge of the balance into the fulcrum and balance the assembly by moving the rider along the arm.

Note: The balance is level when the line on the sight glass is centered across the bubble. - Record the density from the side of the rider nearest the balance cup (the arrow on the rider points to this side). Report the measurement to the nearest 0.1 lb/gal, 1 lb/ft3, 0.01 g/cm3, or 10.0 lb/in2/1,000 ft.

Pressurized Mud Balance

An outstanding advantage of this Mud Balance is that the temperature of the sample does not materially affect the accuracy of readings. A high-impact plastic case protects the balance during transport and provides a secure base in its working position.

Pressurized Mud Balance Equipment

- Fann (convertible density balance)

- 1-qt (946-mL) graduated mud cup

- Thermometer: 32 to 220°F (0 to 104°C)

Pressurized Mud Balance Test Procedure

- Collect a fluid sample.

- Place the base stand or the carrying case on a flat, level surface.

- Measure and record the temperature of the sample, then transfer the sample to the balance cup, filling to between 1/4 and 1/8 inch of the top. Tap the side of the cup several times to break up any entrained air or gases.

- Place the lid on the cup with the check valve in the down or open position.

Note: Some of the test sample may be expelled through the valve. - Rinse the pressurization port and balance with water, base oil, or solvent and dry.

- Slide the cup housing over the balance cup from the bottom, aligning the slot with the balance arm. Screw the closure over the pressure lid and tighten as tight as possible by hand to insure the pressure lid is completely seated.

- Fill the pressurization pump with the test sample.

- Push the nose of the pump onto the pressure port of the lid.

- Pressurize the sample cup by maintaining a downward force on the cylinder housing. At the same time, force the knob down, with 50-70 lbs of force and release cylinder housing. Remove the pump.

Note: The check valve in the lid is pressure actuated. When there is pressure in the cup, the check valve is pushed upward to the closed position. - Clean the mud from the outside of the balance cup and lid. Wipe off any excess water, base oil, or solvent.

- Fit the knife edge of the balance into the fulcrum and balance the assembly by moving the rider along the arm.

Note: The mud balance is level when the line at the sight glass is centered across the bubble. - Record the density from the side of the rider nearest the balance cup. Report the measurement to the nearest 0.1 lb/gal, 1 lb/ft3, 0.01 g/cm3, or 10.0 lb/in2/1,000 ft.

- Reconnect the empty plunger assembly and push downward on the cylinder housing to release the pressure inside the cup.

- Remove the pressure lid being careful not to spill the sample, then pore out the sample. Clean and dry all of the parts of the balance as soon as possible.

Pressurized Mud Balance Tru-Wate Cup

The TRU-WATE Mud Balance is an instrument for measuring the absolute density of a fluid sample. With the TRU-WATE Balance, the density of a fluid sample, such as cement slurry, can be measured in a fixed volume sample under pressure. By pressurizing the sample cup the entrained air or gas can be decreased to a negligible volume, thus providing a slurry density measurement more closely in agreement with the true density which will be realized under down-hole conditions.

Tru-Wate Cup Equipment

- Tru-Wate Cup (fluid density balance)

- 1-qt (946-mL) graduated mud cup

- Thermometer: 32 to 220°F (0 to 104°C)

Pressurized Mud Balance Tru-Wate Cup Test Procedure

- Collect a fluid sample.

- Place the base stand or the carrying case on a flat, level surface.

- Measure and record the temperature of the sample, then transfer the sample to the balance cup.

- Place the lid on the cup with the check valve in the down or open position. Note: Make sure some of the test sample is expelled through the valve.

- Pull the check valve to the closed position.

- Rinse the cap and threads with water, base oil, or solvent and dry.

- Tighten the threaded cap on the cup.

- Fill the plunger assembly with the test sample.

- Push the nose of the plunger onto the mating O-ring surface of the check valve.

- Pressurize the sample cup by maintaining a downward force on the cylinder housing. At the same time, force the piston rod down. Note: The check valve in the lid is pressureactuated. When there is pressure in the cup, the check valve is pushed upward to the closed position.

- Clean the mud from the outside of the balance cup and lid. Wipe off any excess water, base oil, or solvent.

- Fit the knife edge of the balance into the fulcrum and balance the assembly by moving the rider along the arm. Note: The mud balance is level when the line at the sight glass is centered across the bubble.

- Record the density from the side of the rider nearest the balance cup. Report the measurement to the nearest 0.1 lb/gal, 1 lb/ft3, 0.01 g/cm3, or 10.0 lb/in2/1,000 ft.

- Reconnect the empty plunger assembly and push downward on the cylinder housing to release the pressure inside the cup.