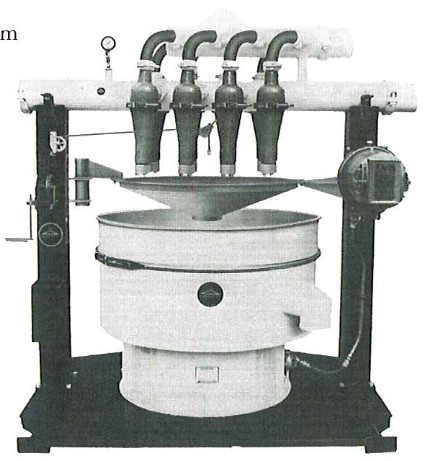

The mud cleaner has a battery of 101.6 mm (4″) desilters mounted over a fine screen shaker. The original reason for its introduction was to separate and save barytes in weighted muds. However, they are now used for low solids mud and oil mud. By accelerating mud through a curved vessel, there will be a separation of solids and mud (Read more about Stokes Law to understand the separation means). These solids will pass over a screen to recover excess fluid.

With weighted muds, picking the correct screen (200 mesh) plays a big role in removing the drilled solids. However, this screen can never remove the silt, which has the same particle size range as the barytes.

With low solids drilling fluids, especially in areas where fluid and cutting removal present a problem, the mud cleaner is useful in combination with a centrifuge for lowering the volume of liquid waste.

With oil-based fluids, desanders and desilters alone are generally inefficient. This is because, the liquid lost via the underflow has often resulted in pollution and disposal problems. That’s the reason for using mud cleaner to remove drilled solids. The liquid will either return to the mainstream or pass through a centrifuge if necessary. So that we will be able to save the oil and dispose of the material will be in dry form.

Mud Cleaner Mechanism & Application

The separation means of mud cleaner depends mainly on a desilter with a screen device. in other words, it is a two-stage process. Firstly, the desilter will process any drilling fluid type. Secondly, a high-energy, fine mesh shaker screen will process the discharge from the desilter. A lot of oil and gas companies will use this mechanism when there are a significant amount of weighting materials or having expensive fluid phases.

While using mud cleaner to recover weight material, any fine solids that pass through the mud cleaner will still be in the mud. This action may lead to the accumulation of fine solids in the drilling fluid.

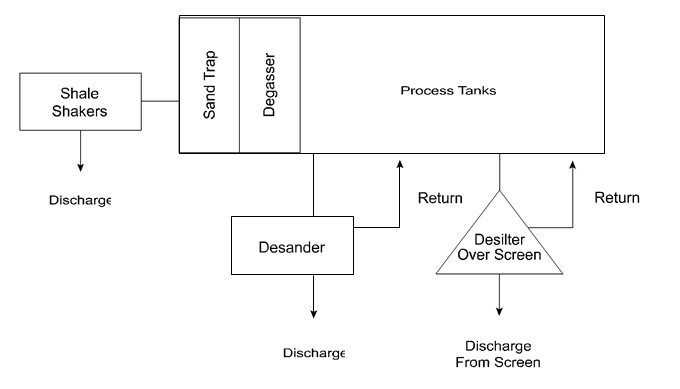

Mud Cleaner Position in the system

As we noted, the common is to position the desilter over a screen as a mud cleaner.

Line Up Mud Cleaner In The Circulating System

The drilling fluid had to pass through many hydrocyclones fixed on a vibrating screen (mud cleaner). At the same time, the return of free solids liquid and particles smaller than the screen openings will be to the circulating system. This process will surely discard solids removed by the screen. We generally use screen sizes from 100 – 325 mesh. As mentioned before, mud cleaners were initially used in weighted fluids for the solid removal of barytes (<74 microns). Noting that shakers could only run 149 microns (100 mesh) screens at best. The development of linear motion shakers limits mud cleaners’ applications.

Many experts recommend installing a good number of fine screen shakers for weighted mud instead of a mud cleaner where possible. The reason is the fine mesh screens of the shakers, which will guarantee to process of all the circulation rates. In addition, mud cleaners will not treat the whole circulation rate. Shale shakers are more dependable, and their screens are more durable.

Mud cleaners have high underflow viscosity of the cone and the small screening area. This feature is the main cause of the increasing barite losses over cleaner screens than that over shaker screens with the same mesh size. Many manufacturers mounted desilter cones over a full-size shaker deck to manage such problems. The special design of Derick High-G shaker improved the cutting’s dryness.

Adding a shaker rather than a mud cleaner at the flowline will increase system efficiency.

Scomi Experts

Mud Cleaners Troubleshooting

Since the mud cleaner is both a hydrocyclone and a shaker, many operating guidelines for these devices apply to mud cleaners.

| Problem | Troubleshooting & Solution |

| Plugged cones or large solids coming off the screen | Check upstream shale shakers For: 1- bypassed screens 2- torn screens 3- dumping the shaker box into the active system |

| Reduction in solids coming off the screen | Change the torn screen |

The desilter cones on the mud cleaner should be the six-inch diameter or smaller. The median cuts of more giant cones are too coarse to be helpful.

Unweighted Muds Recommendations

- In unweighted water-based muds, Experts recommend using the mud cleaner as a desilter. All you have to do is to plug in the screens.

- As we operate the mud cleaner as a desilter, we must run other desilters parallel to the mud cleaner (same suction and discharge chambers). As with desilters, the suction should be from the desander discharge chamber and discharge the overflow to a downstream compartment.

- If the centrifuge processes hydrocyclone underflow, use the finest possible screens to reduce solids loading to the centrifuge.

- We should try to dry the discharge by routing the desanders underflow in closed-loop systems onto the mud cleaner screens. However, we should process the mud passing through the screen by a centrifuge.

- We can also improve the solids removal performance by running the mud cleaner hydrocyclones as wet as possible.

Weighted Muds Recommendations

- Use the mud cleaners when we cannot run 150 mesh (100 microns) screens on the shale shakers (WBM).

- At higher MWT, there may be high volumes of solids. If the screen overloads, remove enough cones to decrease lost mud volumes.

- Monitor the composition and rate of mud losses over the screens, especially in oil-based mud.

- For WBM, dilution water added to the mud cleaner screen may reduce baryte losses by lowering the viscosity of the hydrocyclone underflow. However, there will be a reduction in the amount of discarded drilled solids.

Summary

- Initially, the design of Mud cleaners was for use in weighted mud. That is because of the inability of shakers to handle the size of the weighing material. But, the new fine screen shakers limit the cleaner’s applications.

- A mud cleaner is a desilter combined with a vibrating screen. We can equip the desilter underflow with screens. Fluid and solids finer than the screen will return to the active system. Only solids coarser than the screen openings will get removed.

- In unweighted mud, we should use mud cleaner as a desilter. Screening the underflow is unnecessary unless the mud cleaner screens abrasive solids that a centrifuge will process.

- We recommend the utilization of fine screen shakers in place of mud cleaners. As the screen life is longer, the circulation rate is processed, and barite losses are reported to be lower.

- Use the mud cleaner on existing solids control systems when we cannot run 150 mesh (100 microns) screens on the shakers in weighted mud.

Mud Cleaners Performance Operation

Installation

- We should install the unit so that access is adequate for monitoring and maintenance.

- We must correctly match the centrifugal feed pump to whatever type of mud system to guarantee the correct feed pressure.

- Impeller size and condition is critical to operational efficiency. Any found to have seriously washed; we should replace blades at the earliest opportunity.

- We should give the output of the electrical motor concerning impeller size and mud weight serious consideration. An underpowered pump will seriously affect performance by constantly cutting out.

- For the system to be effective, it must have the capacity to process at least 120% of the maximum circulating rate, ideally 150%. We should check cone sizes and processing rates accordingly.

- Ensure that all cones are in place to maintain system capacity.

Mud Cleaners Operations

- If we didn’t use the system for a considerable time, we should remove all cones and conduct a thorough inspection. We should replace any eroded parts and any clamps that may appear loose.

- We should fit a pressure gauge to the cone manifold.

- Under normal conditions, the screen fitted to the mud cleaner should be finer than the finest suited to the shale shakers.

- Unit underflow should be routed to a catch tank to be further processed by the centrifuge system. The catch tank should be fitted with an overflow facility or equalized with adjacent process tanks.

- During operation, We must monitor the mud cleaner regularly.

- Use a welding rod or similar to unplug any blocked cones immediately.

- If necessary, We should shut the unit down and remove & clean any blocked cones. Operating the mud cleaner with several blocked cones will be highly detrimental to the mud system, surface equipment, and downhole tools.

- If screen flooding is apparent, this may indicate either that the free pressure is too low, resulting in poor separation (practically, there will be underflow discharge of all fluid), or the screen is of too fine a mesh. We should take remedial action immediately.

Notes

- If we use an adjustable screening unit, we should exercise extreme caution in using any adjustment to prevent whole mud carryover. The screen life of the less robust finer screens will be seriously diminished, with any damage resulting in the reintroduction to the system of large quantities of concentrated solids.

- Only use where appropriate: Unweighted mud

- Where the primary solids control cannot screen satisfactorily.

- Ensure the cones are operating correctly

- Always ensure correct feed pressure.

- Rule of Thumb

- Oilfield units: 4 x (MW in lb/gal) | e.g. 12 lb/gal = 48 psi required.

- S.I. units: (M.W. in S.G.) / 0.004 |, e.g., 1438 kg/m3= 360 kPa

- Screen appropriately – 230 mesh or finer.

- Avoid use in oil/synthetic-based systems to avoid solids breakdown.

- Be aware of any mud properties change (as viscosity increases, efficiency decreases!)

At last, mud cleaners are very inefficient, and the need for their use has been replaced by the advent of linear motion shakers combined with centrifuges.

Shell Philosophy