Drilling rigs (check also: drilling rig components) In oil and gas are classified according to field operations into two major types (land rigs and offshore rigs) which in turn are reclassified into other types depending on each rig capability and working environment. Accordingly, rig type can be one of the followings:

- Land/onshore Rigs

- Offshore Rigs

Land rigs

Land rigs are generally either wheel-mounted portable types or a component system that must be moved by trucks and cranes. The drilling floor generally sits on top of a steel substructure that could be 30 feet high or more. A drilling mast (derrick) is attached to and raised above the floor. In general, the deeper wells need a larger, taller rig. The mast must be capable of supporting the vertical load and weight of the stacked drill pipe. It must also withstand wind loads of 100 to 130 miles per hour. Shallow wells and wells being completed or repaired will probably use a portable rig. This rig can be driven to the well site, raised up hydraulically and guy wired in place. When the well is completed, the mast is hydraulically lowered and the rig is driven off.

Offshore rigs

One of the Oil Rig Hazards types is the hostile environment. The effects of greater water depths, storms, wave action, and uncertain exploratory data all greatly increase the financial risks (check Oil Well Drilling Cost Per Foot Formula & Limitations). The exploratory wells must be drilled and a reserve potential established that could justify these costs. These exploratory wells seek to establish new reservoir locations and sizes. Once drilled and evaluated, the exploratory well is most often plugged and abandoned. This results in the use of marine rigs for offshore drilling. The development wells are usually drilled from fixed platforms specially designed to exploit the reserves of the reservoir. The platform (platform rig) is also used for production facilities after all drilling operations are complete.

The environment also determines which type of marine rig will be used. Each rig has advantages and disadvantages when used in different water depths and weather conditions. The type of marine rig also can depend on problems involved in getting the rig on location and keeping it stationed in the desired position. The choices include

- The jackup rig,

- Semi-submersible rig,

- The submersible rig,

- Drilling ship rigs type,

- Platform rig,

- The inland barge rig, and

- Tension leg platform.

Jackup Drilling rigs Type:

The jack-up rig has replaced the submersible rig as a fixed drilling platform. It is less costly to build and can operate in up to 600 feet of water. It is ideal for soft ocean sediments found in river deltas.

The jack-up rig consists of a watertight hull and three or more mobile legs. The legs are raised up to allow the vessel to be towed to a location. Then the legs are carefully jacked down until each rests on the seabed. The hull is then jacked up on the legs until it is above the predicted height of storm waves. This height depends on the area and the season. It varies in the Gulf of Mexico from 25 to 35 feet and in the North Sea up to about 95 feet for the worst storm conditions to be expected. Because the jackup is also set on the seabed, it does not have heave problems. It can have vessel motion problems during bad weather if jacked to the top of the legs. This eliminates the need for most motion compensation equipment and special mooring and anchoring equipment.

To move the rig between close locations the platform is lowered down the legs until it floats then the legs are jacked up to the maximum height. The whole rig can then be towed by means of two boats. In long rig moves of this type (check also: Rig Audit, Acceptance & Commissioning Procedures) or across oceans the whole drilling rig is normally carried on a huge oil and gas carrier type.

Disadvantages include its difficulty in towing, especially in rough seas; the legs must be removed during long moves.

Semi-submersible Type Of Drilling rigs:

Semi-submersible rigs are floating rigs supported on pontoons. A common design consists of four, five, or six legs. Older semi-submersibles are kept on location by means of anchors and chains, whereas some of the newer ones are kept on location by means of thrusters. The pontoons can be re-floated to change locations. They can be towed easily or even self-propelled to the new location.

The semi-submersible rig evolved from the older submersible rigs. It can provide a relatively stable drilling platform. It can operate under more serve weather and sea conditions and in water depths from 600 to 4,000 feet.

The semi-submersible rig contains a normal working deck plus columns and pontoons under the deck. These pontoons are ballasted to a water depth that causes the upper deck to remain high above the water. Semi-submersible rigs are the elephants of the offshore rigs, capable to continue operation in bad weather. Semi-submersible rigs move with the tide the drilling penetration rate must be corrected for the influence of the tidal heave.

The disadvantages of semi-submersible: rig types are that they require marine drilling risers and a subsea stack, have limited cargo capacity, and require support vessels.

Drill ship

Drill ships are ships specially built and modified to drill in deep water or in operations that are not suitable for semi-submersible rigs. Drill ships are self-propelled and can carry larger loads of drilling supplies. This makes them more mobile and self-supporting in remote ocean areas. The drill ship is capable of drilling in waters up to 9,000 feet. It also offers advantages of faster travel times, are self-propelled, and can use dynamic positioning systems.

Drill ships rigs are differentiated from other offshore drilling units types by their easy mobility. While semi-submersible rigs can also drill in deep waters, drill ships are able to propel themselves from well to well and location to location, unlike semi-submersible, which must rely on an outside transport vessel to transfer them from place to place.

The disadvantages of oil and gas drilling ships types include high salaries for the ship’s crew who are not directly involved in the drilling operations. In addition, the drill ship is greatly affected by wave motion (heave) and drifting. This requires a motion compensation system, a marine riser system, and/or a mooring and anchoring system or thrusters for dynamic positioning.

Transocean, Pride, Seadrill Oil, Frontier Drilling, and Noble are a few of the companies that own and operate this type of rigs globally.

Platform rigs

If the exploration drilling program is successful in finding a commercial reservoir, a development program must be planned. All facilities needed to drill, produce, store and transport the hydrocarbons must be designed, fabricated, and installed on the site.

All fixed platforms must be able to withstand the environmental forces of their region. This could include wind, waves, currents, ice, earthquakes, and soil conditions.

The platform generally consists of four to eight piles or legs resting or driven into the seabed. Drilling slots on the platform are arranged in a grid system. The actual drilling rig will be skidded from slot to slot for each well. The individual wells will be drilled at an angle to allow for efficient production of the reservoir. A fixed drive pipe extends from a subsea template to the substructure of the platform. The BOP stack is connected to the fixed drive pipe for each well slot as it is drilled. Because of its location, the stack is easier to install, repair or change sizes.

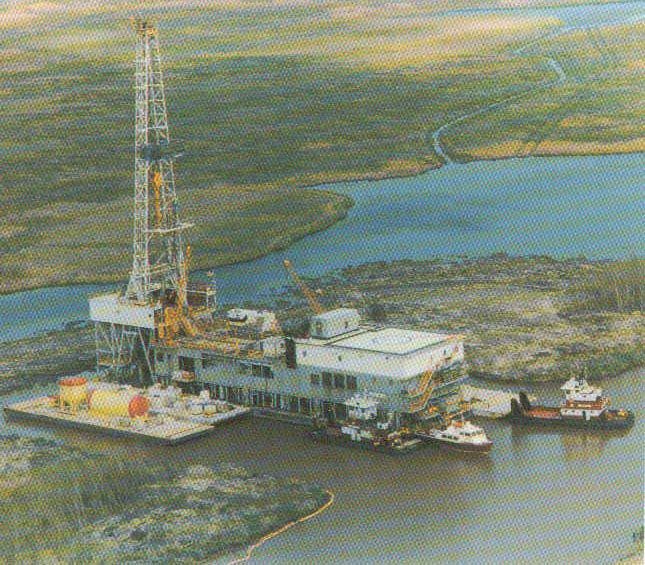

Inland barge Drilling rig Type:

A drilling structure consists of a barge upon which the drilling equipment is constructed. When moved from one location to another, the barge floats. When stationed on the drill site, the barge can be anchored in the floating mode or submerged to rest on the bottom. Typically, inland barge rigs are used to drill wells in marshes, shallow inland bays, and areas where the water covering the drill site in not too deep. Also called swamp barge.

The inland barge rig is the oldest form of the marine rig. It consists of two hulls, which are connected by legs. The upper hull is air-tight and provides the buoyancy necessary to float the rig to each site. The rig is positioned over the site and the lower hull is flooded. This causes the rig to sink until it rests on the seafloor.

After drilling the well, the rig is re-floated and moved to a new location. The inland barge rig is limited to working in relatively shallow water, less than 50 feet normally. They are also hard to move to new locations.

Tension leg platforms:

The Tension Leg Platform is one of the newest types of rig available. This type is a combination of a drilling semi-submersible rig and a platform rig. It is used strictly for production drilling. Normally, some of the wells in the field have already been drilled, and then the TLP is positioned over the pre-drilled wells and the production lines run to the existing wellheads.

They are set up with drilling equipment in the event other wells need to be drilled, or any existing wells must be worked over. The current technology allows the TLPs to work in up to 5,000 feet of water.

The platform is permanently moored by means of tethers or tendons grouped at each of the structure’s corners. A group of tethers is called a tension leg. A feature of the design of the tethers is that they have relatively high axial stiffness (low elasticity), such that virtually all vertical motion of the platform is eliminated. This allows the platform to have the production wellhead on deck (connected directly to the subsea wells by rigid risers), instead of on the seafloor. This allows a simpler well completion and gives better control over the production from the oil or gas reservoir, and easier access for downhole intervention operations.

TLP’s have been in use since the early 1980s. The first Tension Leg Platform was built for Conoco’s Hutton field in the North Sea in the early 1980s. Larger TLP’s will normally have a full drilling rig on the platform with which to drill and intervene on the wells. The smaller TLPs may have a workover rig, or in a few cases, no production wellheads located on the platform at all.