Definition of Oil Rig and its Uses

Oil rigs are large structures that play a crucial role in the oil and gas industry by allowing for drilling exploratory wells and extracting hydrocarbons from beneath the Earth’s surface. This article will delve into the uses of oil onshore & offshore rigs and the safety regulations and practices that govern their operations. In addition, we will focus on the importance of environmental protection in the oil and gas industry.

Exploration and Drilling Operations

Oil rigs are primarily utilized for exploratory drilling operations. Geologists and engineers analyze seismic data to identify potential oil and gas reservoirs. Once a promising location is identified, an oil rig is positioned to drill a well. These wells can extend thousands of feet below the surface. In addition, they are equipped with various systems to extract and transport the oil and gas to production facilities. Exploration and drilling operations require adherence to strict safety procedures and regulations to ensure the well-being of rig personnel and the environment.

Production Operations

In addition to exploration and drilling, offshore platforms (Platform Rig) are responsible for production operations. Once oil and gas are successfully extracted from the reservoir, they are processed and transported via pipelines or vessels for further refining or distribution. Production facilities on the platform are equipped with various equipment and systems to separate impurities and stabilize the extracted hydrocarbons. These operations also require strict safety measures to prevent accidents and maintain the integrity of the production process.

Oil Rig Safety Regulations and Environmental Protection

Safety is a top priority in the oil and gas industry, and oil rigs are subject to numerous safety regulations and standards. USA Federal agencies, such as the Bureau of Safety and Environmental Enforcement (BSEE) in the United States, enforce safety requirements and conduct inspections to ensure compliance. Oil rig workers must follow safe practices, wear protective equipment such as safety glasses, and undergo training to prevent accidents and injuries. Additionally, environmental protection is of utmost importance in offshore drilling operations. Stringent regulations are in place to prevent oil spills, minimize the impact on marine ecosystems, and promote sustainable practices.

In conclusion, oil rigs are integral to the oil and gas industry; they may serve as platforms for exploration, drilling, and production operations. These structures adhere to strict safety regulations and procedures to ensure the well-being of workers and prevent environmental damage. The importance of safety and environmental protection cannot be overstated in the industry, as both human lives and the ecosystem rely on the safe operation of oil rigs.

Purpose of Oil Rig Safety Regulations

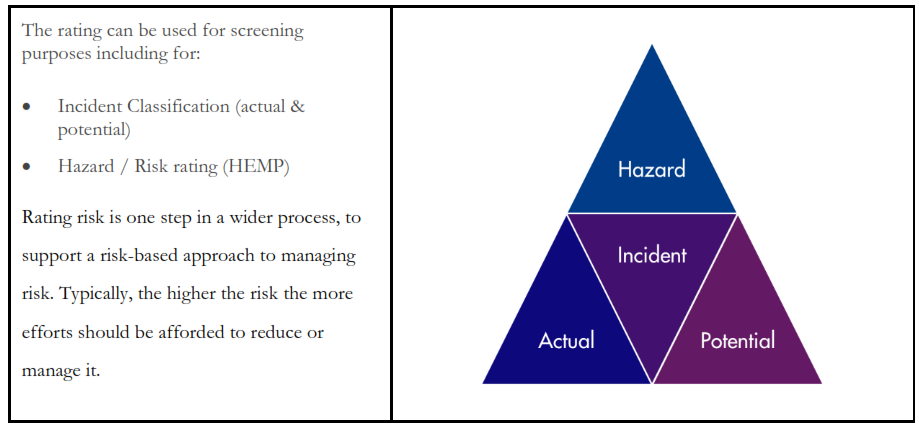

Safety regulations for oil rig operations serve two critical purposes: worker protection and environmental preservation.

- First and foremost, these regulations are in place to ensure the safety and well-being of oil rig workers. Oil rig operations can be dangerous, with potential rig hazards such as heavy machinery, high-pressure systems, and harsh weather conditions. Compliance with safety regulations helps minimize the risk of accidents and injuries. Also, it will ensure that workers can perform their tasks in a safe environment. By implementing safety measures, providing workers with proper training, and enforcing procedures, the industry aims to protect its workforce.

- Secondly, safety regulations aim to prevent environmental damage and preserve ecosystems. Offshore drilling activities have the potential to harm marine life and cause oil spills, which can have devastating consequences for the environment. Stringent regulations require oil rig operators to employ safe work practices. Furthermore, implementing spill prevention measures and adhering to standards minimize their impact on surrounding ecosystems.

Enforcing safety procedures is crucial for maintaining a safe work environment. Regular rig inspections and audits ensure that safety measures are correctly implemented and followed. Training programs enable workers to understand and adhere to safety protocols effectively, reducing the risk of accidents and injuries.

Violating safety regulations can lead to severe consequences. Accidents may result in injuries, loss of life, and property damage. Environmental damage from oil spills can be catastrophic and have long-lasting effects on marine life and ecosystems. In addition to these immediate consequences, violating safety regulations can lead to legal penalties and fines for oil rig operators.

Industry Standards and Best Practices

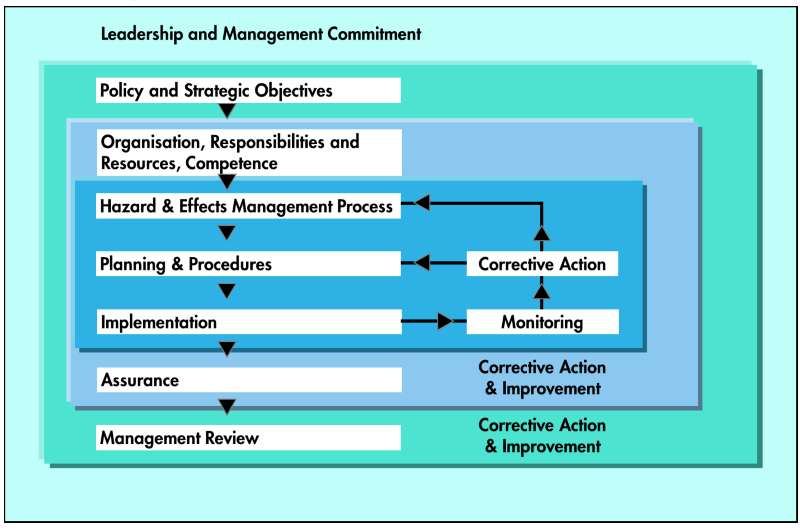

In the oil rig industry, adhering to industry standards and best practices is of utmost importance to ensure the safety and efficiency of operations. Regulatory bodies, industry associations, and experienced professionals develop these standards and practices to establish guidelines and protocols that address common safety concerns and promote responsible environmental management. Following these standards, oil rig operators can mitigate risks, prevent accidents and environmental damage, and maintain a safe and efficient workplace.

These guidelines cover various aspects, including equipment maintenance, well-control procedures, personnel training, emergency response plans, environmental protection, and compliance with federal regulations. Implementing industry standards and best practices is essential for creating a safety culture and continually improving the overall performance of oil rig operations.

Professional Engineer Qualifications for Oil Rig Operations

Working on an oil rig requires a high level of skill and expertise, especially when it comes to ensuring safe and efficient operations. That is where professional engineers play a crucial role. These individuals are highly qualified and possess the necessary certifications to carry out their responsibilities on oil rigs.

Professional engineers working on oil rigs must have a solid educational background in engineering. They typically hold a bachelor’s degree in an engineering discipline such as petroleum, mechanical, or electrical engineering. Additionally, they must have a professional engineer (PE) license obtained through rigorous examination and verification of their engineering experience.

With their qualifications and certifications, professional drilling engineers bring knowledge to oil rig operations. They are well-versed in safety procedures, environmental protection, and industry standards. Their expertise ensures that all safety measures and regulations are adhered to, mitigating risks and protecting workers and the environment.

Moreover, skilled engineers contribute to efficient operations on oil rigs. They use their technical knowledge to optimize processes, streamline production, and address any problems that may arise. This not only enhances productivity but also maximizes the safety and overall performance of the rig.

In conclusion, professional engineers are an essential component of oil rig operations. Their qualifications and certifications demonstrate their expertise in ensuring safe and efficient practices. The oil rig industry benefits from enhanced safety measures, compliance with regulations, and improved operational efficiency by having skilled engineers on board.

Common Sense Guidelines for Safe Operation

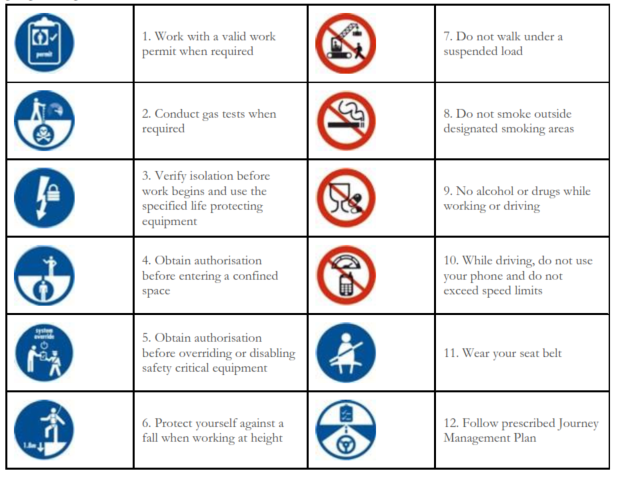

Adhering to safety procedures is of utmost importance when working on an oil rig. These guidelines are in place for a reason – to protect the well-being of workers and minimize potential hazards. Oil rig workers can ensure a safe and secure working environment following safety protocols.

Wearing proper personal protective equipment (PPE) is another essential facet of maintaining safety on oil rigs. PPE includes safety glasses, hard hats, gloves, and protective clothing. These items act as a shield against potential injuries and provide necessary protection in case of accidents or emergencies.

Drilling Rig Supervisors and managers are critical in enforcing safety procedures and ensuring compliance. They are responsible for monitoring and correcting unsafe behaviors or conditions promptly. Supervisors and managers can set the tone for safe operations on the rig by promoting a safety culture.

Investing in quality PPE is crucial for preventing injuries. Inferior or ill-fitting equipment can be ineffective and compromise worker safety. By providing high-quality PPE, employers can significantly reduce the risk of accidents and injuries.

In conclusion, adherence to safety procedures, proper usage of PPE, diligent oversight by supervisors and managers, and the provision of quality equipment are all common-sense guidelines that contribute to safe operation on oil rigs. By following these guidelines, workers can ensure safety and minimize risks in this challenging and demanding industry.

USA Federal Oil Rig Safety Regulations

Federal regulations play a crucial role in ensuring the safety of oil rig workers and protecting the environment. These regulations are established by government agencies such as the Bureau of Safety and Environmental Enforcement (BSEE) in the United States. They set standards and guidelines for offshore drilling operations, production facilities, and gas industry operations. These regulations cover a wide range of aspects, including safety standards, environmental protection measures, and the use of proper safety equipment.

They also address well-controlled fluids, oil spills, and extreme weather conditions. Adhering to these regulations is essential to maintaining a safe workplace and preventing accidents or incidents that could harm personnel, the environment, and the surrounding communities. Employers in the gas and oil industry must ensure compliance with these federal regulations to create a safe and secure working environment for their employees.

Overview of Regulatory Bodies

Several regulatory bodies oversee and enforce safety regulations in the industry to ensure the safety of oil rig operations. These regulatory bodies play a crucial role in setting and maintaining safety standards, overseeing compliance, and ensuring the safety of oil rig workers and the environment.

One of the key regulatory bodies involved in oil rig safety is the Bureau of Safety and Environmental Enforcement (BSEE). As an agency within the U.S. Department of the Interior, the BSEE regulates and enforces safety and environmental standards for offshore drilling operations. Their primary function is to develop and implement safety guidelines, conduct inspections, and enforce compliance with regulations.

Another significant regulatory body is the Occupational Safety and Health Administration (OSHA). OSHA is a part of the U.S. Department of Labor responsible for ensuring safe and healthy working conditions for employees across various industries, including oil rig workers. OSHA establishes standards, conducts inspections, and provides training to promote workplace safety.

Additionally, the American Petroleum Institute (API) plays a significant role in setting industry standards and guidelines for oil rig safety. API develops recommended practices and certifications widely adopted by the oil and gas industry to ensure safe operations and equipment.

These regulatory bodies, along with others such as the Environmental Protection Agency (EPA) and the Coast Guard, work together to establish and enforce safety regulations, perform inspections, investigate incidents, and ensure compliance with safety standards in the oil rig industry. By fulfilling their roles and responsibilities, these regulatory bodies contribute to preventing accidents, protecting workers, and preserving the environment.

Review of Current Oil Rig Safety Regulations

In response to the Deepwater Horizon tragedy, the oil rig industry has implemented heightened drilling safety standards and containment capabilities to prevent future disasters and protect workers and the environment. These regulations are overseen and enforced by the Bureau of Safety and Environmental Enforcement (BSEE), ensuring compliance and periodically updating rules to reflect technological advancements.

The BSEE plays a vital role in enforcing oil rig safety regulations by conducting inspections, evaluating safety practices, and taking appropriate enforcement actions. They collaborate with industry stakeholders to develop and revise protocols that enhance safety measures and prevent accidents.

To effectively communicate these regulations, the BSEE relies on various channels. They provide comprehensive rules and guidance on their website, which serve as essential references for oil rig operators and workers. They also issue Notices to Lessees and Operators to disseminate important safety information and updates. Moreover, interested parties can participate in rulemaking processes by submitting comments and feedback through Regulations.gov, ensuring transparency and accountability in the regulatory process.

Additionally, the BSEE reviews and approves oil spill response plans. They provide regulatory interpretations to assist operators in understanding and complying with requirements. This ensures that the industry maintains high standards in mitigating and responding to oil spill incidents, further emphasizing the BSEE’s commitment to oil rig safety.

Potential Changes to Existing Regulations

The gas industry constantly evolves, so the oil rig safety regulations must also adapt. Potential changes to existing regulations in the gas industry aim to further enhance safety procedures and environmental protection in gas drilling.

These changes could significantly impact safety procedures by introducing new protocols and requirements that operators must adhere to. This could include implementing stricter safety measures and guidelines, improving training programs for oil rig workers, and ensuring the use of advanced safety equipment and technologies.

Environmental protection is also a priority when it comes to potential changes in regulations. The focus is on minimizing the impact of gas drilling on the environment by implementing more stringent measures for waste disposal, controlling emissions, and monitoring water quality. These changes would safeguard ecosystems and protect the environment from potential harm associated with gas drilling operations.

Specific changes being considered or proposed include stricter regulations on well-controlled fluids, real-time data to monitor environmental conditions, and developing or revising safety and environmental management systems. These changes aim to ensure that the gas drilling industry operates in a safe and environmentally responsible manner.

Overall, potential changes to existing regulations in the gas industry reflect a commitment to continuous improvement in safety procedures and environmental protection. The industry can maintain a safe workplace and minimize its environmental impact by staying current with evolving safety standards and technologies.