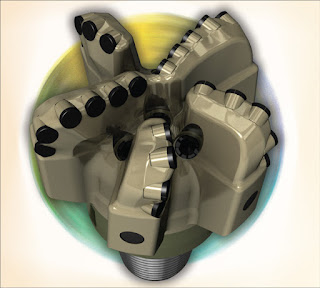

As it is mentioned in Schlumberger Oilfield Glossary, PDC Bit is a drilling tool that uses polycrystalline diamond compact (PDC) cutters to shear rock with a continuous scraping motion. These cutters are synthetic diamond disks about 1/8 in. thick and about 1/2 to 1 in. in diameter. PDC bits are effective at drilling shale formations, especially when combined with Oil Based Mud. It is also essential to understand PDC Bit Design as it will be related to the drilling parameters. PDC bit designs are generally based on high or low RPM applications, i.e., turbine vs. rotary drilling. Turbine applications use more blanks to compensate for friction-related wear considerations. The PDC bit is tapered to allow the placement of the cutters. PDC bits for rotary applications have fewer cutters and a somewhat flat design.

First, What Parameters Affecting Drilling With PDC Bit

Optimum Hydraulic Range

PDC bits do not have the benefit of the self-fluid-cleaning action between rows of teeth like roller cone bits, so they must rely on the bit’s hydraulics to flush the cuttings from under the bit to prevent bit balling. This is accomplished with strategically positioned converging-diverging nozzles, which maximize cleaning while minimizing body erosion near the nozzle area. The optimum hydraulic range is between 2.0 to 4.0 hydraulic horsepower per square inch. The interchangeable jet nozzles come in standard sizes from 8/32s to 14/32’s.

The cutting structure controls bit life. As stated earlier, the PDC cutting elements provide a self-sharpening edge with the wear resistance of diamonds. This combination is very effective in soft to medium formations such as shale, chalks, limestones, clays, salts, and anhydrite. These formations have been drilled at excellent penetration rates with weights between 1000 and 2500 pounds per inch of bit diameter and rotary speeds of 85 to 140 rpm.

PDC Drilling Parameter “PDC Bit Rotary speeds.”

Economic performance has also been achieved with rotary speeds of 750 rpm and weights of 1000 pounds per inch of bit diameter using a Downhole Mud Motor. High rotary speeds provide better drill rates and reduce the chances of deviation. The optimum rotary speed varies with formation hardness. A soft, plastic formation would require a higher rpm; a complex formation a lower rpm. Most applications require rotary speeds of less than 120 rpm.

PDC Drilling Parameter “Weight On Bit”

Lighter weight-on-bit means lower stress on the drill string, with increased string life. There’s less drag in directional holes because fewer drill collars are required, reducing the potential for the stuck pipe.

Oil & Water Base Mud & PDC Bit Parameters

These bits have made economic runs in both oil and Water Based Mud. Oil base muds and adding lubricants to water base muds will enhance PDC bit performance (Also check: Roller cone bit performance) in formations that tend to be somewhat plastic and sticky.

Try To Avoid These Formations While Drilling With PDC Bit

Formations that should be avoided with PDC bits are soft, sticky shales and clays, abrasive sands, and those formations which are very hard. In sticky formations, PDC bits tend to ball up; cutter wear and breakage occur rapidly in abrasive or complex formations.

PDC bits cannot drill as broad a range of formations as roller cone bits but have shown to be competitive with diamond bits. Thus, care must be taken when selecting bits for various applications. When properly applied, most PDC bits can be run in more than one well.

PDC bit cost (check also drilling cost per foot) savings are measured in terms of tripping pipe time saved, longer bit life, improved rates of penetration, and fewer rig hours required to drill a well.

Now, Let’s Move To PDC Bit Drilling Parameters & Precautions

Even though PDC bits have achieved recognition as a viable tool for improved drilling, certain precautions and drilling parameters should be met to make the bit run as efficiently and economically as possible.

- When the last bit is removed, it should be inspected for any damage. If junk was left in the hole, do not run a PDC bit until the hole is cleaned.

- When removing the bit from its box, handle it carefully. Do not roll it out on the rig floor. If the bit is dumped on the floor and some cutters are chipped, the bit’s life will be reduced.

- The interior of the bit should be inspected to ensure no debris is left inside.

- The proper bit breaker should be used to make up the bit.

- The bit is one solid piece and does not have the limited flexibility of roller cone bits. Hitting ledges or running through tight spots can damage the gauge cutters.

PDC Bit Drilling Parameters While Reaming In Hole

If it is necessary to Ream when going into the hole, pick up the kelly and run the maximum flow rate. The rotary speed should be about 60 and slowly go through the tight spot.

PDC Bit Drilling Parameters While near bottom

When Drill String becomes near the bottom, the last joint should be washed down slowly at full flow and 40-50 rpm to avoid plugging the bit with any fill. Observe the Torque and weight indicators to locate the bottom of the hole. Because of the type of cutting structure on PDC bits, it is expected that the first on-bottom drilling parameter is a sudden increase in torque.

After the bottom of the hole has been reached, the bit should be lifted a foot or two off the bottom, then circulate and rotate slowly for about five minutes to ensure the bottom of the hole is cleaned.

PDC Bit Drilling Parameters While Drilling

When ready to start drilling, bring the drilling parameter rotary speed up to 60 and approach the bottom. Lightweight should be used to cut a new hole pattern. At least 1 foot of a new hole should be cut in this manner before looking for optimum weight and rotary speed for drilling.

- In soft formations, the bit will drill quickly with light parameters (lightweight and rotary speed) and then should be increased until the bit is drilling at its fastest rate (usually between 100-150 rpm).

- In hard formations, it will take much longer to drill one foot. Adding weight too quickly will damage the cutters. Once the bottom hole pattern is established and weight is added, watch the Torque indicator for possible problems.

There is no limit to rotary speed; use as much as possible without damaging the rest of the Drill String.

How To Know From PDC Drilling Parameters That PDC Is Not Suitable

The on-bottom torque should approach what is experienced with roller cone bits. If there is no torque buildup, or the penetration rate does not increase with added weight, the formation may not be suitable for PDC bits.

What Precaution To Consider After Making Connection

After making a connection, the bit should be washed back down to bottom. Dropping and then stopping the drill string suddenly can cause the bit to hit bottom and be damaged due to pipe stretch.

PDC Bit Drilling Parameters & Formation Change

PDC bits respond dramatically to changing formations, if the Penetration Rate (ROP) suddenly decreases or the bit starts torquing, a change in the weight-on-bit and rotary speed should help.

How PDC Drilling Parameters Tell You That Your PDC Is Weared

When the cutters wear to a point where they will not drill, the bit should be pulled. If the wear is primarily on the outside, there will be a sudden decrease in two PDC bit drilling parameters which are penetration rate and torque, and an increase in standpipe pressure. If the wear is on the gauge portion, there will be very high on-bottom torque with little weight-on-bit and a decrease in the penetration rate.

Useful Papers Related To PDC Bit Drilling Parameters

Investigation of Various ROP Models and Optimization of Drilling Parameters for PDC and Roller-cone Bits in Shadegan Oil Field

According to the field data, there are several methods to reduce the drilling cost of future wells. One of these methods is the optimization of drilling parameters to obtain the maximum rate of penetration (ROP) in each bit run. Many parameters affect ROP like hole cleaning (including drillstring rotation speed (N), weight on bit (WOB), floundering phenomena, mud rheology), tooth wear, formation hardness (including depth and kind of formation), differential pressure (including mud weight (MW)), etc

Single PDC Bit Run Parametric Evaluation and Optimization Effect on ROP with Considering Bit Wear

The most effective approach to reduce the cost of drilling oil and gas wells is to increase penetration rate. To reduce well construction costs substantially, drilling time must be reduced. Major reductions of time spent in other activities or categories would not have an overall impact as significant as reducing drilling time due to increase in ROP. Several approaches can be considered for reducing total drilling time; however, the most effective way is to improve drilling efficiency. Moreover, an increase in rate of penetration (ROP) must be accompanied by equal (or greater) equipment reliability so that overall trip time is maintained ………

Technology Update: Aggressive Drilling Parameters, PDC-Bit Innovations Cut Run Times in Abrasive Oklahoma Granite Wash

A combination of new drill-bit technology and new operational practices has enabled operator Marathon Oil to use polycrystalline-diamond-compact (PDC) drill bits, and reduce drilling time by 24%, on wells in a part of the Anadarko basin where abrasive conditions at shallow depths previously have required the use of roller-cone bits