Drilling bits cut rock by five basic mechanisms

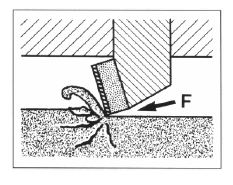

- Wedging.

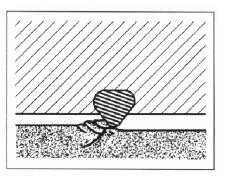

- Scraping and Grinding.

- Erosion by fluid jet action.

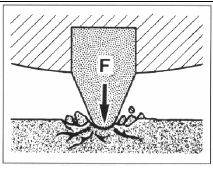

- Crushing.

- Torsion or Twisting.

While one mechanism may be dominant for a given bit design, more than one mechanism is usually present.

PDC Bits

- PDC bits cut rock primarily by wedging, which is more efficient than crushing and grinding.

- In the right formations, the wedging action makes it possible for PDC bits to maintain high penetration rates with less weight on bit.

- This reduces wear a bit while yielding high ROP.

Natural diamond bits

- Natural diamond bits are designed to drill with very small penetration into the formation.

- The diameter of sandstone grains may not be much smaller than the depth of penetration of the diamonds.

- The drilling action of diamond bits is primarily a grinding action in which the cementing material holding the individual sand grains together is broken by the diamonds

Rolling cutter bits

- Roller cutter bits designed with small or zero offset angle for drilling hard formations employ the crushing mechanism for rock removal.

- This cutting action is inefficient and requires high weight on bit to deliver enough energy to the formation to achieve fast penetration.

- The drilling action of rolling cone bits designed with a large offset angle for drilling soft formations is more complex than the simple crushing action.

- Since each cone alternately rolls and drags, considerable wedging and twisting action is present in addition to the crushing action.