Conventionally, one will drill a well and use heavy drilling fluids to control the well pressures and to control the flow of cuttings from the well. Sometimes, using air or gas as the circulating medium or using light mud to drill in an underbalanced condition is beneficial. You must use a rotating drilling head when drilling with air or gas or underbalanced drilling.

The rotating head can be defined as a rotating, low-pressure sealing device used in drilling operations to seal around the drill stem above the top of the blowout preventer stack.

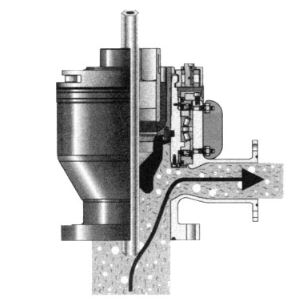

Rotating drilling heads are used to safely divert air, gas, dust, or drilling mud away from the rig floor. The head has a rubber device called a stripper rubber that provides a continuous seal around the drill stem components, thus directing the drilling medium through a side outlet on the body and away from the rig floor. They are also used for closed-loop circulating systems in environmentally sensitive areas.

Note: You should always remember that rotating drilling heads are diverter Systems and that you must never use them as a blowout preventer.

Applications Of Rotating Drilling Heads in Oil & Gas Wells

Air and Gas Drilling

Air and gas drilling were the first applications for rotating drilling heads. Typically, air and gas drilling is used in very hard formations and extremely fractured formations. Benefits of air and gas drilling include:

- Faster penetration rates, sometimes threefold to fourfold, compared to mud drilling.

- Reduced formation damage.

- Fewer wellbore problems, such as lost circulation and sloughing of sensitive shales.

- Immediate indication of zone productivity.

- Reduced mud cost.

Underbalanced Drilling

Underbalanced drilling is where the hydrostatic pressure created by the drilling fluid column is less than drilling, include:

- Reduced formation damage.

- Accurate and immediate evaluation of well potential.

- Improved production rates.

- Increased Drilling penetration rates.

- Reduction in drilling problems associated with pressure-depleted zones, such as Pipe Sticking and lost circulation.

- Reduced drilling time and costs.

Role of Rotating Head in Flow Drilling

Flow drilling is the process of producing the well while drilling. You drill the producing zone underbalanced to allow flow from the formation into

- Horizontal wells with fractured formations.

- Preventing damage to producing formation(s).

- Preventing plugging of fractures while drilling and well completion.

- Reducing drilling time and costs (check also oil well drilling well cost per foot).

Geothermal Drilling

Geothermal drilling is where you drill into steam-producing formations, thus allowing steam to flow up the wellbore to the surface. The steam must be diverted from the rig floor for safety. Rotating drilling heads specifically designed for geothermal drilling typically have two sealing elements (stripper rubbers). The upper stripper rubber seals around the kelly while drilling and the drill pipe and tool joints when tripping in and out of the hole. The lower stripper rubber has a larger ID to allow sealing around the larger drill stem components, such as drill collars.

Rotating Drilling Heads Components

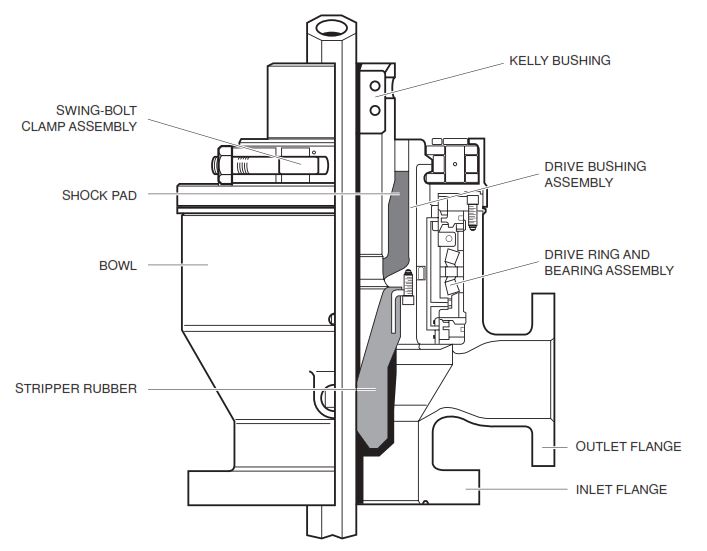

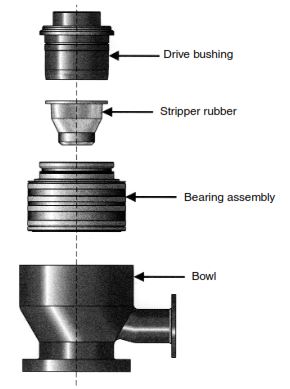

Most rotating drilling heads have five major components (see Figure 2).

- (a) Bowl with integral inlet and outlet flanges or (b) body with separate spool having inlet and outlet flanges.

- Stripper rubber.

- Drive ring and bearing assembly.

- Drive bushing assembly with Kelly drive bushing and clamp.

- Lubricator system (not shown).

Bowl Assembly with Integral Inlet and Outlet Flanges

The bowl assembly is installed on top of the BOP stack and below the rotary table. The bowl is stationary and has a clamp assembly that firmly locks the drive ring and bearing assembly to the body.

Rotating Drilling Head Body Assembly with Separate Spool Having Inlet and Outlet Flanges

The spool is installed on top of the BOP, and the body fits on top of the spool. The two are held together by a clamp assembly or by clamping dogs. Both the spool and the body are stationary.

Stripper Rubber

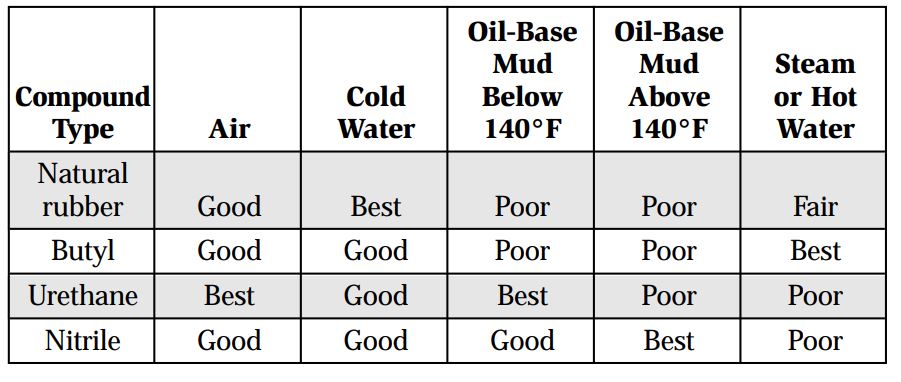

The stripper rubber is either fastened to the bottom of the drive bushing or molded integral with the assembly. The purpose of the stripper rubber is to provide a seal around the kelly as it is rotated and to seal around the drill pipe while tripping in and out of the hole. It is easily changed by opening the clamp and lifting the drive bushing assembly (and stripper rubber) out of the bowl. Stripper rubbers are available in different elastomer compounds for the various drilling environments such as high temperatures and oil-base muds

Rotating Head Drive Ring and Bearing Assembly In Drilling

The drive ring and bearing assembly support the torsional and axial loads on the rotating drilling head and also provide low torque rotation. The bearing assembly consists of two heavy-duty tapered roller bearings, an upper and a lower. The bearing assembly is sealed to keep contaminants out of the bearings while retaining the lubricating oil around the bearings.

Drive Bushing Assembly

The drive bushing engages a lug on the drive ring and is then clamped onto the drive ring. The drive bushing drives the drive ring and bearing assembly. The kelly bush drives the drive bushing itself [1]ing which is fitted onto the kelly. The Kelly bushing automatically engages when the Kelly is lowered into the drive bushing. The drive bushing has a rubber insert to absorb lateral shock loads transmitted from the kelly to the kelly bushing.

Lubricator System

The lubricator system must be used in conjunction with the bearing assembly. The lubricator provides oil under pressure to the bearings for cooling and longer bearing life. Lubricating systems can be circulating or non-circulating. Circulating lubricating systems are recommended for high-temperature operations such as geothermal drilling.

References

BHA Smith Drilling Data Handbook