Sand Content Kit

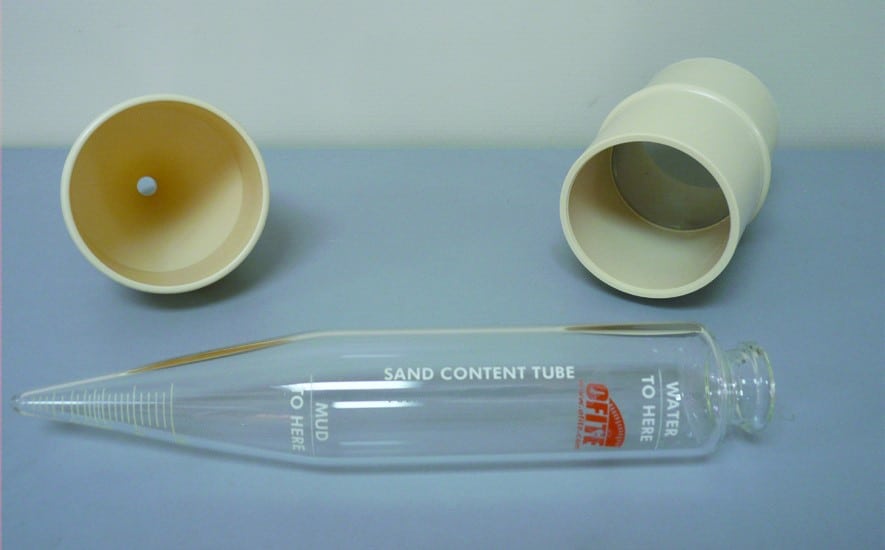

A sand content kit is used for measuring the sand content in water-based drilling mud or oil-based drilling mud, comprising a 200-mesh sieve, a plastic funnel, and a graduated glass tube that is calibrated to measure the sand content as a percentage. The 200-mesh sieve is designed to trap particles that are larger than 74 microns, which is much coarser than barite particles. However, the sieve will also trap other coarse particles (e.g. coarse Calcium Carbonate LCM particles), which could distort results if ignored. Every effort must be made to keep sand content as low as possible because it is extremely abrasive and can damage mud pumps and tubular, as well as cause an undesirable increase in mud density.

- Well Blowout

- Jar Intensifier

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

Testing Procedure For Sand Content

The following procedure is used for measuring sand content by its previously discussed kit:

1. Fill the graduated glass tube with a sample of mud to the line marked, “Mud to Here”.

2. Fill the rest of the graduated glass tube with clean water to the line marked, “Water to Here”.

3. Place a thumb over the mouth of the glass tube and shake vigorously.

4. Pour the contents of the graduated glass tube onto the 200-mesh sieve, tapping the side of the sieve to improve flow and discarding everything that passes through the screen.

5. Refill the graduated glass tube with clean water and repeat the process until all residual solids have been removed from the glass tube.

6. Wash the sand particles trapped in the sieve under running water, gently rubbing the sand particles with the tip of a finger to break up and flush away any clay particles.

7. Place the funnel over the sieve and then place the tip of the funnel in the mouth of the clean, empty graduated glass tube.

8. Use gentle running water on the reverse side of the sieve to flush all the sand particles into the graduated glass tube without over-filling.

9. Allow time for the sand to settle at the bottom of the graduated glass tube and record the sand content as a percentage of the mud volume; along with the mud sampling location (e.g. flow line, active tank, etc.).

10. Wash the components of the sand content kit and leave to drain.

The graduated glass tube may contain other coarse solids, such as LCM and Calcium Carbonate, but these should be easy to identify because the heavier sand will settle first. If the “sand” at the bottom of the graduated glass tube contains a significant amount of Calcium Carbonate, then the water should be poured away without disturbing the “sand”, and acid should be added to dissolve the Calcium Carbonate. The real sand content (% by volume) can then be recorded.