A tool joint is a heavy coupling element for drill pipe. Tool joints have coarse, tapered threads and seating shoulders designed to:

- Suspend the weight of the drill string.

- Withstand the strain of frequent makeup and breakout.

- Provide a leakproof seal.

The tool joint is attached to the pipe by welding during the manufacture of the drill pipe joint (API drill pipe specifications). It has two parts, a pin and a box.

Tool Joint Strength

The strength of tool joints depends on several factors: the material used to make the tool joint, the dimensions of the joint, and the type of thread used. The strength of the pin may be different from that of the box.

Material Strength

For API tool joints, the material yield strength is the same, regardless of the tube grade to which it is fitted. All API tool joints have a minimum yield strength of 120,000 psi.

Considering the above, one may think fitting a tool joint with a minimum yield strength of 120,000 psi to a grade S tube with a minimum yield strength of 135,000 psi may be ridiculous. However, the minimum tensile yield of the new 5″, S grade, 19.5 lbs/ft nominal wt tube is 712 k.lbs. The minimum tensile yield of an NC50 connector is 1,390 k.lbs (2.75″ ID, pin weak). The weakest part of the tool joint has a larger cross-sectional area than the tube and is, therefore, stronger.

Pin Weak Or Box

“Pin weak” means that the pin is weaker than the box. This can mean a tensile or torsional weakness relative to the box. “Box weak” is the other way around. The box is weaker than the pin.

Drill Pipe Tool Joint Torsional Strength

The main factors that control tool joint torsional strength are the pin or box metal cross-sectional area and the minimum yield strength of the metal. Tool joint OD affects the box cross-sectional area, and tool joint ID controls the pin cross-sectional area.

It is usual for the tool joint OD to wear down during service. If the box cross-sectional area becomes less than the pin cross-sectional area, that joint’s torsional strength will be reduced (box weak).

The API sets the joint torsional strength at an arbitrary value of about 80% of the tube torsional strength. This 0·8 design factor is used to establish the tool joint IDs and ODs for all three classes of drill pipe.

Conclusion:

- Most standard API tool joints are weaker in torsion than the Drill Pipe tubes to which they are welded.

- API arbitrarily sets tool joint torsional strength at 80 percent of tube torsional strength. This tool joint torsional strength ratio (TSR) of 0.8 is the basis for establishing tool joint ID and OD.

- As the drill pipe tool joint OD wears, the torsional strength decreases. Tool joints with TSRs less than 0.8 are used successfully in low torsion drilling, and some high for torsion drilling applications require tool joint torsional ratings higher than the standard TSR of 0.8.

Drill Pipe Make-Up Torque

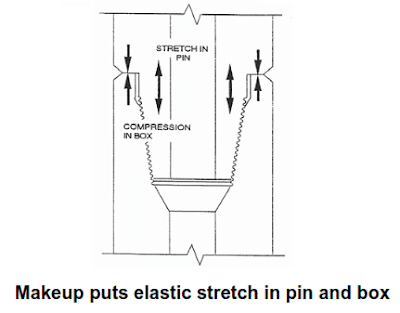

- Tool joints are made up by applying sufficient makeup torque to force the pin and box shoulder tightly together and make a seal. This is accomplished when makeup stretches the pin and compresses the box shoulder.

- Makeup torque is determined by the tool joint OD and ID and not by the properties and dimensions of the drill pipe tube. For a given pin ID, the makeup torque increases as the tool joint OD increases. Similarly, the makeup torque decreases as the pin ID increases for a tool joint OD.

- The standard makeup torque is the torque that would stress the weaker pin or box to 60% of its minimum yield strength of 72,000 psi. (Minimum yield strength of all tool joints is 120,000 psi regardless of the drill pipe grade).

Selection Of Drill Pipe Tool Joints

The major factors to be considered while the selection of tool joints are as follows:

- Outside diameter

- Inside diameter

- Tensile

- Torsional ratings

- Cost

Simple Tips To Be Considered While Tool Joint Selection:

- Tool joints with large OD and small ID will result in high-pressure losses inside and outside the Drill Pipe.

- Large OD tool joints have better wear characteristics.

- The OD of the tool joint should be small enough to facilitate fishing the tool joint with standard fishing tools.

- One rule of thumb in selecting tool joints is that when all other factors are equal the larger the tool joint, the better it will perform.