After taking an influx, closing the BOP stack & shutting in the well, pressure will build up on the standpipe and casing gauges. This is because of the hydrostatic under balance (drilling fluid weight too low to balance formation pressure). The pressure on the standpipe manifold is “Shut In Drill pipe Pressure” SIDPP, and what appears on the casing gauges is called “Shut In Casing Pressure” SICP.

As long as the drill string contains the original weight drilling fluid, SIDPP will always exist as an extra pressure registered at the surface required to balance formation pressure. Usually, we use SIDPP & SICP in kill sheet calculations to determine the kill mud weight.

Reading Shut In Drill Pipe (SIDPP) & Casing Pressure (SICP)

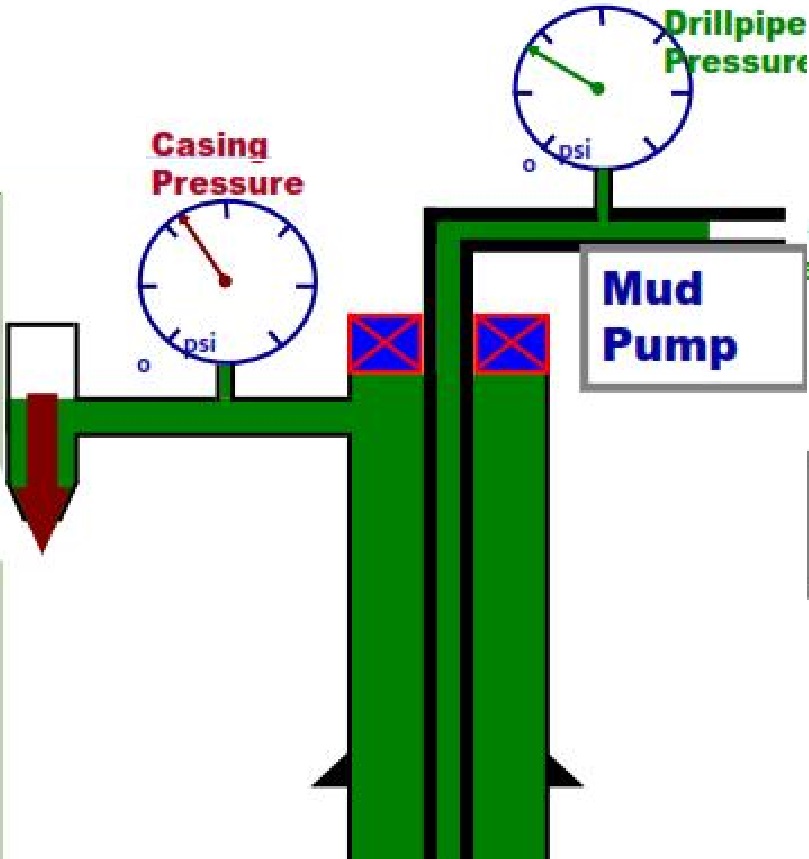

SICP: We will need to line up valves on the drilling spool and choke manifold. This lineup is to transmit wellbore pressure to the closed drilling choke. In addition, reading the shut-in casing pressure should be from a gauge upstream of the closed choke.

SIDP: If no float is in the bottom hole assembly, we can read SIDPP from a pressure tap on the standpipe. Actually, most drill strings should have floats installed, which will require bumping to determine the SIDP.

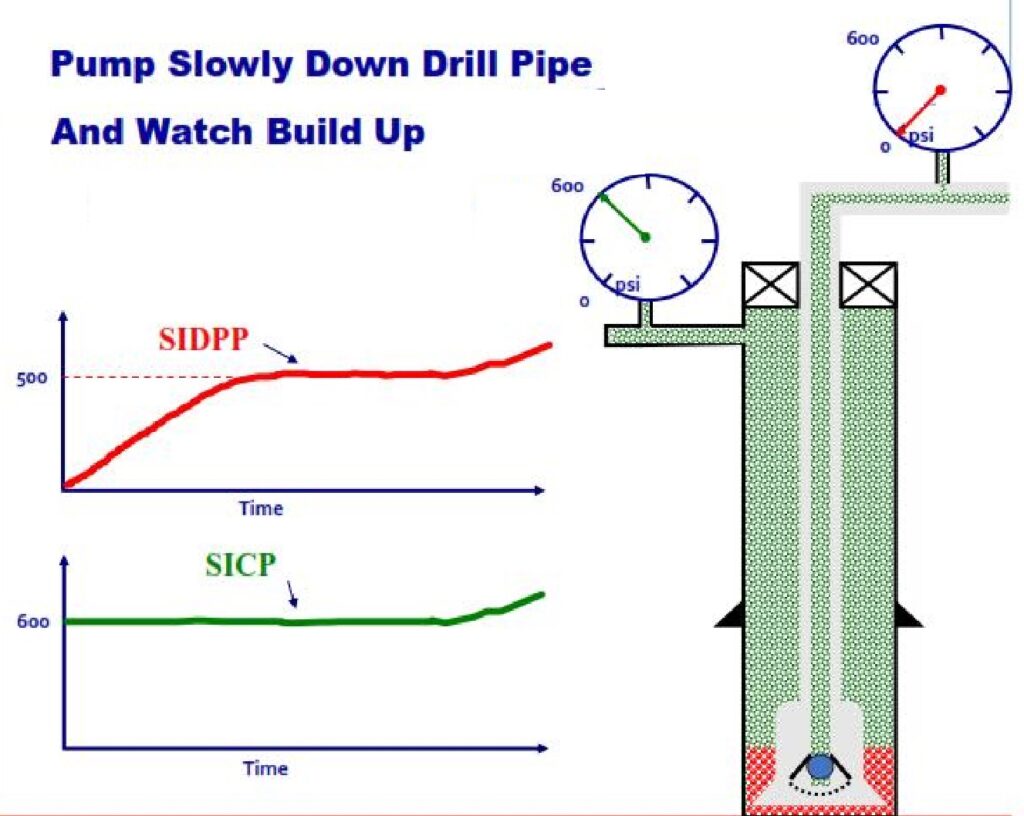

Float Bumping Procedure:

- Start the mud pump at a low speed while keeping the casing pressure constant.

- The drill pipe pressure will keep increasing till it starts hesitating.

- Once there is a simple drop in drill pipe pressure, record the reading.

Understanding Of SIDPP & SICP.

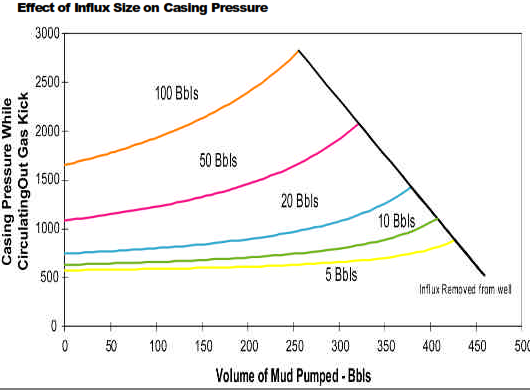

Shut-in surface pressures depend primarily on the amount of underbalanced and the amount & density of the influx. Shut-in drill pipe and casing pressure indicate the difference between formation pressure and the hydrostatic pressures in & out of the drill pipe. In fact, the amount of the under balance equally affects both shut-in pressures. More specifically, the more significant the difference between formation and hydrostatic pressure, the larger the shut-in pressures. Higher shut-in casing pressures can cause formation breakdown in this instance. Early detection and quick closure of the preventers are essential to decrease influx volume. Also, this will decrease the likelihood of excessive downhole pressures. In addition, the resultant breakdown at the casing seat (also check: MAASP).

Shut in Drill Pipe & Casing Presures Comparison

Usually, the shut-in casing pressure is greater than the shut-in drill pipe pressure because of the low-density formation fluids in the annulus. In this case, the total hydrostatic pressure in the annulus is less than that in the drill pipe, so it requires a higher shut-in casing pressure to balance the formation pressure. The difference in hydrostatic pressures between the annulus and drill pipe depends on the volume (height) of the influx and its density. The shut-in casing pressure for a gas kick is much higher than for a saltwater and/or oil kick of equal volume.

SIDPP = SICP Situation

Often, the shut-in drill pipe and casing pressures will read the same when shutting in with the drilling bit off the bottom. In other words, when all or most of the formation fluids are below the bit. In this case, the reduction of hydrostatic pressure caused by the low-density influx affects the drill pipe and casing pressures equally. A similar condition will occur with a hole in the drill pipe (washout) and with all of the influx trapped below the hole.

Final Thoughts

When considering the effects of the under balance and size of influx on downhole pressure, we must consider the position of the influx fluid in relation to the depth of interest. If the depth of interest is above the kick, the total amount of the shut-in casing pressure must be added to the mud hydrostatic pressure to that depth. If, however, the depth of interest is within the interval of the kick or below, then the total effect of surface pressure on the depth of interest is less. This also applies when the kick fluid is circulated out of the hole. For example, the shoe pressure at a shallow casing seat will typically increase while circulating a gas kick until the gas reaches the casing seat. At this point, the shoe pressure will drop until the gas is in the casing. Until all the gas is removed from the annulus, the shoe pressure at the casing seat will be constant. The location of the kick fluid in the annulus concerning the depth of interest will determine the effect of excessive casing pressure on the shoe pressure.