Wellbore strengthening can be achieved by utilizing stress cage pill theory through drilling mud types in the wellbore using bridging particles (marble and graphite) and an ultra-low fluid loss mud system. This theory is considered as a solution for the Lost Circulation Problem.

Wellbore strengthening is designed to strengthen the wellbore so that depleted reservoirs can be drilled with higher mud weights without inducing downhole losses due to formation breakdown (i.e. the fracture resistance of the formation is increased).

Application Of Wellbore Strengthening

- Drilling depleted reservoirs adjacent to formations with higher pore pressures.

- Deep water drilling with a narrow window between pore pressure and fracture gradient.

- Minimizing losses when running or cementing casing.

- Providing improved well control.

- Reducing the number of casing strings in a well.

For Example, in depleted reservoirs, the pore pressure gradually declines as the reserves decline, weakening hydrocarbon-bearing rocks. However, adjacent and inter-bedded low permeability shales may maintain their pore pressure, making drilling extremely difficult because the mud weight to support these shales exceeds the fracture resistance of the depleted sands and silts.

How To Achieve Wellbore Strengthen By Stress Cage Theory ?

Below steps will explain how this mechanism go:

- Short fractures are deliberately allowed to form at the wellbore wall.

- The bridging particles and a mud filter cake rapidly form at the fracture mouths.

- The fractures are then propped open by the bridging particles (marble) and ultra low fluid loss filter cake prevents fluid invasion across the mouths of the bridged fractures.

- Adjacent rock is put into compression by the fractures to form a “stress cage”, which effectively strengthens the wellbore.

Stress Cage Theory

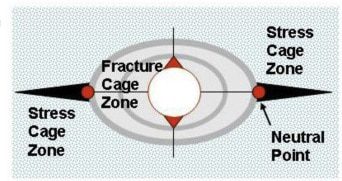

The theory behind stress cage wellbore strengthening associated with drilling mud is depending on the following points:

- Allow small fractures to form in the wellbore wall.

- Hold them open using bridging particles near the fracture opening.

- The bridge must have low permeability to provide pressure isolation.

- This will create an increased hoop stress around the wellbore (a “stress cage” effect), provided the induced fracture is bridged at, or close to, the wellbore wall.

The aim is to be able to achieve this continuously while drilling, by adding appropriate materials to the any Water-Based or Oil-Based mud system, producing in effect a “designer mud”.

Theory suggests that increases in effective wellbore strength of around 1,000 psi can be achieved with fracture widths as small as 1 mm. Particle size distribution (PSD) in the fluid would need to range from colloidal clays up to values approaching 1mm, to give a smooth PSD profile and produce a low permeability bridge. PSD would then need to be maintained while drilling.

Theory also suggests that short fractures are best, so it is necessary to arrest fracture growth very quickly as the fracture starts to grow (long fractures are easier to re-open and propagate). This means high concentrations of bridging additives are preferable. The drilling mud additives need to be physically strong enough to resist the closure stresses, and sized to bridge near the fracture mouth to produce a stress cage near the wellbore.

Permeable Formations

In stress cage theory, the particle bridge does not need to be perfect when drilling permeable formations because fluid passing through the bridge will leak away from the fracture into the rock matrix, so there will be no build-up in pressure in the fracture to initiate fracture propagation. Even if a filter cake forms initially on the walls of the fracture, the fracture would grow by a small amount to expose new surface and this would relieve the pressure.

If the mud contains particles that are too small to bridge near the fracture mouth, the fracture could still become sealed as filter cake built up inside the fracture. However, the sealing/bridging will be slower and the fracture length might extend too far to form a useful stress cage effect while drilling. This can be seen in the mud losses observed using ordinary mud systems. However, one advantage of running ultra-low fluid loss muds in permeable formations is the reduced risk of differential pipe sticking.

Low Permeability Formations

The particle bridge needs to have extremely low permeability when drilling low permeability formations because this will prevent pressure transfer into the fracture, which would otherwise initiate fracture propagation. This explains the need for fluids that produce filter cakes with an extremely low fluid loss. The initial rush of mud fluid into the fracture when it forms will deposit the bridging solids at the fracture mouth, but a differential pressure is then required to hold this bridge in place to achieve stress cage theory while drilling.

A slow pressure leak-off into the shale may maintain this pressure differential, but ultra-low fluid loss is required so that the bridge at the fracture mouth has sufficiently low permeability to maintain differential pressure across the bridge. With a low permeability bridge, flow rate of fluid into the fracture is extremely small once the bridge has formed. If pressure builds in the fracture, then the fracture would only need to grow by a small amount to relieve this pressure. Therefore, it may suffice to achieve a bridge with very low permeability rather than “zero” permeability.

The ideal scenario for the stress cage drilling theory would be the formation of many narrow localized fractures around the wellbore to produce the stress cage, which would then require very small bridging particles from the mud system to seal them. This never happens in reality, which is why larger bridging particles are also required. An important factor is to form a stable bridge that is flexible enough to withstand the fluctuations in pressure and rock movements, which explains why graphite is included in the bridging particles.

Operational Considerations For WellBore Strengthening By Stress Cage

Running designer muds requires non-standard drilling practices. The circulating system must be loaded with larger bridging solids and the PSD must be maintained with continuous additions of these larger materials. Optimally, around 40 ppb bridging solids must be kept in the system. Coarser Shaker screens must be used to avoid stripping out bridging particles while circulating, which means that the mud weight and rheology will gradually increase due to the build-up of drilled solids. As a result, more dilutions may be required while drilling.

A lot of service companies uses stress cage theory solutions for wellbore strengthening:

- BaraECD® fluid system and WellSET® wellbore strengthening treatment

- Integrated Borehole Strengthening Solutions (I-BOSS)