Die Collars (box taps) and taper taps fishing tools are two types of attachments that are used in fishing operations to screw into a fish. Die Collars have threads on the ID, which cut threads into the OD of the fish, externally engaging the pipe. Taper types are used to engage the inside of a fish where conventional releasing spears would not be feasible. They can be ordered with right-hand or left-hand wickers and the normal taper is ¾” per foot.

Box Taps Or Die Collars Fishing Tools Operations

Like taper tap, box tap or die collar tools are sometimes used to retrieve an irregularly sized fish or a fish with an unknown OD. You do not need to know what kind of threads the fish has because the box tap cuts its own threads. However, the fish needs to be stationary for the box tap to be successful. Box taps are not typically recommended because they are not releasable. For that reason, a safety joint should always be run immediately above a die collar fishing tool.

Running procedure for a box tap Fishing Tool

- Trip-in-hole (Tripping Pipe Procedure) to the top of the fish, turn mud pump and circulate any cuttings off the fish.

- Tag the fish lightly and rock the rotary to thread the tap onto the fish.

- As the tap cuts threads onto the fish, slack off while watching the weight indicator to accommodate for thread makeup.

Note: It is difficult to gauge the correct amount of torque to apply while making up a tap. However, when made up properly, a box and taper tap can hold up to 100,000 pounds.

- Use straight pick up to pull the fish.

Caution: Tripping the drilling jar might free the tap from the fish.

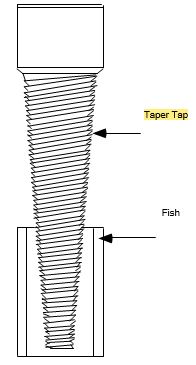

Taper Tap Fishing Tool

Taper tap fishing tools have threads on the OD, which cut threads into the ID of the fish. They internally engage the fish, inhibiting circulation through the fish. They are usually only considered as a last resort.

This tool screws into the fish and cuts threads as it goes. Cutting new threads is a more positive engagement than attempting simply to screw on or into existing threads on a fish that may be damaged, misaligned, or incomplete. New threads can also be cut on the blank pipes. Frequently, the Taper Tap is used to retrieve a production packer after the slip segments and packer element have been milled with conventional mills.

Their Disadvantages include that they:

- First, they do not allow wireline instruments to pass-through

- Second, they can be brittle and may break

- Third, they are non-releasable.

To avoid breaking it, do not bump down on it. Also, because taper tap fishing tools are non-releasable, run a safety joint and a bumper sub.

Running Procedure For The Taper Tap Fishing Tool

- Run Taper Tap into the hole and lightly tag the top of the fish.

- Pick up and begin to rotate slowly. Note the free torque of the work string.

- While rotating, slowly lower the Taper Tap into the fish until the torque begins to build up rapidly.

- Increase the set-down weight as the torque increases.

- Once the Taper Tap is firmly seated in the fish, attempt to retrieve the fish with a straight pull (dependent upon the fishing scenario).

Caution: Again, Taps are non-releasable and should be run with bumper jars and safety joints. Taps should only be used when releasable engagement-type tools are not an option.