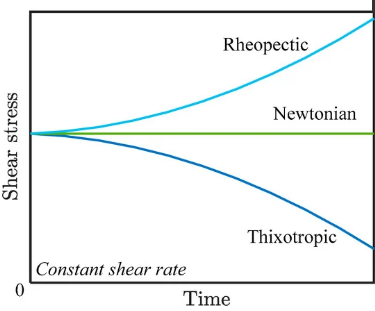

Thixotropic cement slurry in oil and gas is a system that has the capability to develop a self-supporting gel structure. This structure carries part of the hydrostatic pressure of the cement column, thereby reducing the pressure against the formation. This is significant in a low gradient situation where heavy fluid losses would otherwise be experienced and/or fractures induced due to the high overbalance. Shear breaks the (fragile) gel structure, making it possible to pump a thixotropic cement formulation. Before we delve deeper, you might be interested in learning about cementing in drilling.

White, F.M. Fluid Mechanics fourth edition; McGraw and Hill: Singapore, 1994. [Google Scholar]

Conversely, in the absence of shear forces, a high gel strength develops rapidly, countering or completely stopping fluid loss or loss of circulation. Contrary to ordinary cement properties (rheology), which largely follow the Power Law relation between shear stress and shear rate, thixotropic cement behaves more like a Bingham plastic fluid. They exhibit a ‘yield value,’ i.e., minimum stress has to be applied to initiate movement.

Chemicals Of Thixotropic Cement Slurry In Oil & Gas

Thixotropic properties can be induced by adding one of the following cement additives to regular Portland cement formulations:

- Hydrateable clays such as bentonite in concentrations between 0.5% and 2% bwoc.

- Calcium sulfate is a calcium sulfate hernia-hydrate (CaSO4.1/2H2O, also known as plaster of Paris). This material forms the mineral ettringite through hydration to gypsum and reaction with Portland cement’s tri-calcium Aluminate (Ca3A) component. Ettringite deposits onto the cement grains and promotes a physical association into a network. Concentrations range from 5% to 12% bwoc.

- In thixotropic cement slurry, aluminum/Iron(II) sulfate also generates ettringite, but in this case, through Al2(SO4)3 reaction with lime liberated when cement hydrates. The ferrous sulfate acts as a retarder to compensate for the powerful acceleration of cement setting by the aluminum sulfate and to render a slurry that remains pumpable for a requisite time. Because this system does not rely on the Ca3A, it can be applied to Portland cement low in this component.

- Cross-linked cellulose polymer. Cross-linking cellulose polymers such as hydroxy ethyl cellulose (HEC) or carboxy methyl hexa ethyl cellulose (CMHEC) with a suitable agent generate a strong progressive gel.

Oil & gas thixotropic cement also offers the possibility of adjusting the slurry gradient by varying the water/cement ratio. The addition of 10% bwoc of calcium sulfate hemihydrate permits increasing the water requirement to 0.65 m3/tonne (7.9 USG/sack) dry cement to yield a slurry with a gradient of 16.7 kPa (0.738 psi/ft) from 0.43 m3/tonne at a gradient of 18.3 kPa/m (0.809 psi/ft).