Have you ever wondered what keeps the pipes and other oilfield equipment threads tightly sealed? The answer lies in a small but essential product known as thread compound. Thread compounds are used in casing, tubing, line-pipe, or drill string on every threaded connection. For the purposes of this topic, we will deal only with the type used on tubing and casing.

Thread compounds for tubing and casing were initially developed by the Mellon Institute of Industrial Research, funded by an API research project, to satisfy the following objectives:

- Adequate lubricating qualities to prevent galling in threaded connections during makeup.

- Sufficient inert filler must prevent leakage in API casing and tubing joints under up to 68,950 kPa (10,000 psi) pressure.

- There is no tendency to become excessively fluid at temperatures up to 1500C.

- Readily applicable by brush to pipe joints in cold weather.

- The thread compound properties will not change due to instability, dryness, or oxidation.

- Resistance to water absorption.

- No tendency to disintegrate nor undergo radical change in volume at temperatures up to 1500C (3000F).

- Sealing properties to prevent leakage at temperatures as high as 1500C.

Source: https://trenchlesstechnology.com/importance-thread-compound-hdd/

Threads Compound Composition

The two most common types of compound used in tubular make-up are API and API Modified. Both compounds are a mixture of metallic and graphite powders, uniformly dispersed in a grease base, the proportions being 64% solids and 36% grease base.

The solids should be a composition of the following materials:

- Powdered graphite (28%)

- Lead powder (47.5%)

- Zinc dust (19.3%)

- Copper flake (5.2%)

API and API modified have the same percentage and constituents of solids. The difference between the two is the grease base. Whereas the API-modified thread compound has a 36% grease-only base, the API has a base consisting of 20.5% grease, 12.9% silicone compound, and 7.2% silicone fluid.

The silicone inclusion improves low-temperature properties and may improve application to water-wet threads but does not necessarily improve anti-galling or sealing capabilities. These properties are a function of the powdered solids’ specific combination quantities and particle size.

Sealing

The types of solids used in thread compounds are predominantly ductile, relatively weak, low melting point materials, which will deform readily when pressure is applied. When the joint is tightened, the metal powder particles will fill all the minor tool marks, impressions, and imperfections in the joint as they compact together.

Generally, in an API tubing and casing connection, the thread compound will fill the voids left between the pin and box thread crests and roots, or flanks, and together with the bearing pressure affected by the mating of the surfaces, will provide a pressure seal. In an API connection, therefore, the primary function of the thread compound is to provide a sealing capability.

In a premium connection, the role of the thread compound as a sealing agent is secondary, as the primary seal relies on the mating of at least one set of finely machined metal/metal seals. However, the function of the thread compound as a lubricant is still essential. Correct application to the surfaces of mating connections is necessary to prevent galling, ensure smooth running, and assist in break-out.

Thread Compounds Coefficient of Friction

The amount of rotation can be controlled by the coefficient of static and dynamic friction of the compound. Much of the applied torque will be expended in overcoming friction that a highly coefficient compound will produce. Therefore, rotation will be limited. The same torque applied to a low co-efficient compound allows more rotation as less torque is required to overcome friction. In general, lubricating oils, Teflon, lead, graphite, and sulfur, decrease the friction coefficient, and zinc, copper silicates, zinc-oxide, and non-lubricating oils increase the friction coefficient.

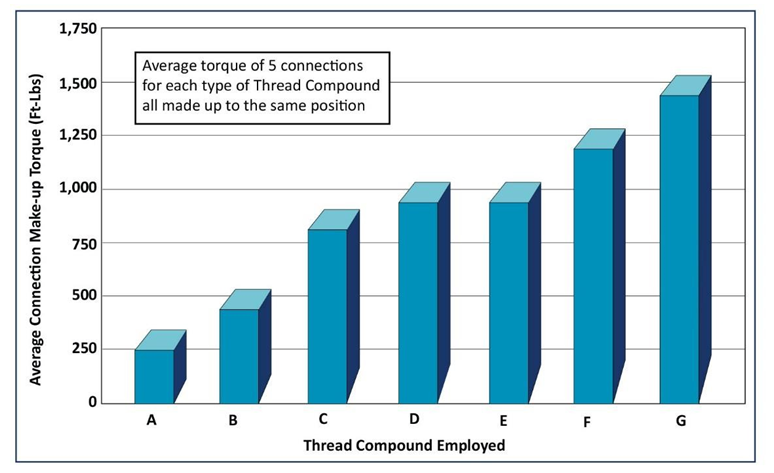

Figure 1 above shows the effect of make-up torque on the amount of angular rotation using A) low friction coefficient and G) high friction coefficient thread compounds. Note that excessive make-up causes high stresses to be set up in the thread roots, and severe damage can occur in the form of stretched pins, cracked threads, or cracks through the joints.

Deformation

Flattening and elongation of the metal powder particles require energy. This energy is supplied in the form of torque. The greater the density of particles, the more torque is required for deformation and crushing. A table of the relative yield strengths of the metal powders is shown in the table below. It can be seen that more torque is required to deform copper or zinc particles than Teflon, graphite, or lead. The deformation rate significantly affects the angular rotation of the connection. The faster the torque is applied, the more stress is required to deform the particles, reducing the angular rotation for a given torque.

| Materials | Yield Strength | |

| kPa | (psi) | |

| Copper | 68,948 | 10,000 |

| Zinc | 20,684 | 3,000 |

| Lead | 4,137 | 600 |

| Graphite | 1,379 | 200 |

| Teflon | 1,379 | 200 |

Work Hardening

Work hardening is the property of a metal to resist deformation as deformation continues. Once yield stress is reached, the additional stress required to deform the particle is significantly higher. In most thread compounds, additives such as lead oxide, zinc oxide, and silicates produce dispersion hardening. These secondary particles become embedded in the metallic powders during crushing, further increasing the deformation resistance.

The above properties relate to the importance of the thread compound as a lubricating, anti-galling, and sealing agent. The rotation limiting characteristics relate to non-shouldered connections, and it must be remembered that the primary function of the use of thread compounds with premium connections is that of lubricating and anti-galling agents.

Thread Compound Practical Use

As we have seen, thread compounds have lubricating properties and reduce friction between pin and box threads during make-up. This directly relates to the torque necessary to properly make up a connection. The greater the friction present, the greater the torque necessary to overcome it. Different thread compounds lubricate to different extents, and we consider the different properties of various thread compounds by using correction factors or thread compound friction coefficients. Published data on torque figures are based on a factor of 1, as with API-modified dope.

The correct torque figure for a different thread compound is then derived by multiplication of the appropriate factor. In practical terms, this means we need to know for sure the connection type and torque figures, and when using other than API-modified thread compound, we need to be sure of the type of thread compound and its correction factor (if it is more or less than 1).

Equally important when using any thread compound is to ensure that it is thoroughly stirred after opening a new can and that it is never mixed or adulterated with any other substance (such as diesel etc.). In cold or Arctic conditions, warming of the thread compound may be necessary to enable it to be brushed onto the threads.

Environmentally Friendly Compounds

New types of thread compounds are coming onto the market to eradicate the use of ‘unfriendly’ ingredients such as lead. Questions to be considered when reviewing a new compound include:

- What is the correct correction factor for the compound?

- Does the compound have good anti-galling properties?

- Will the compound aid in breaking out the connection?

- How does the compound affect the graph profile?