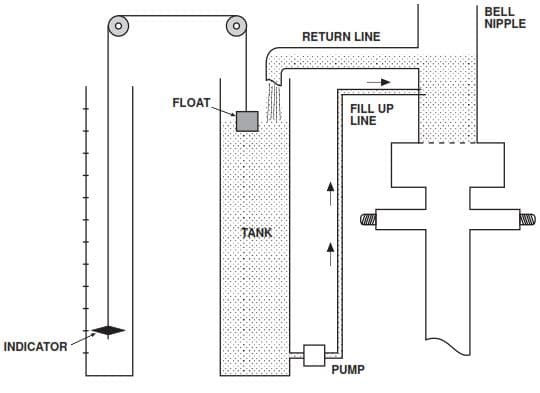

We usually use a calibrated trip tank in drilling to measure mud volumes accurately and change mud volumes while tripping. It must be available on all rigs & must have a level indicator easily readable from the driller’s position. Such an indicator must be accurate to within one-half barrel volume.

It is unsafe to trip without a trip tank, so we should keep spare parts for the hole-fill pump/motor at the rig site.

A TRIP TANK is any pit or tank in which the mud volume can be measured accurately to within +/- 1.0 bbls. As the pipe is pulled from the hole, the mud from the tank is allowed to fill the hole as needed, which at the same time denotes the amount of mud being used.

ENI Rig Book

Drilling Trip Tank Definition

A trip tank is a low-volume, calibrated tank that can be isolated from the remainder of the surface drilling fluid system and used to accurately monitor the amount of fluid going into or coming from the well. A trip tank may be of any shape provided it is calibrated accurately and a means is provided for reading the volume contained in the tank at any liquid level.

The readout may be direct or remote, preferably both. The tank size and readout arrangement should be such that volume changes in the order of one-half barrel can be easily detected. Tanks containing two compartments with monitoring arrangements in each compartment are preferred as this facilitates removing or adding drilling fluid without interrupting rig operations.

Trip Tank Application In Drilling

The primary use of the trip tank is to measure the amount of drilling fluid required to fill the hole while pulling the pipe to determine if the drilling fluid volume matches pipe displacement. Other uses of the trip tank include measuring drilling fluid or water volume into the annulus when there is lost circulation & returns are lost, monitoring the hole while logging or following casing cement job, calibrating drilling fluid pumps, etc. The trip tank is also used to measure the volume of drilling fluid bled from or pumped into the well as the pipe is stripped into or out of the well.

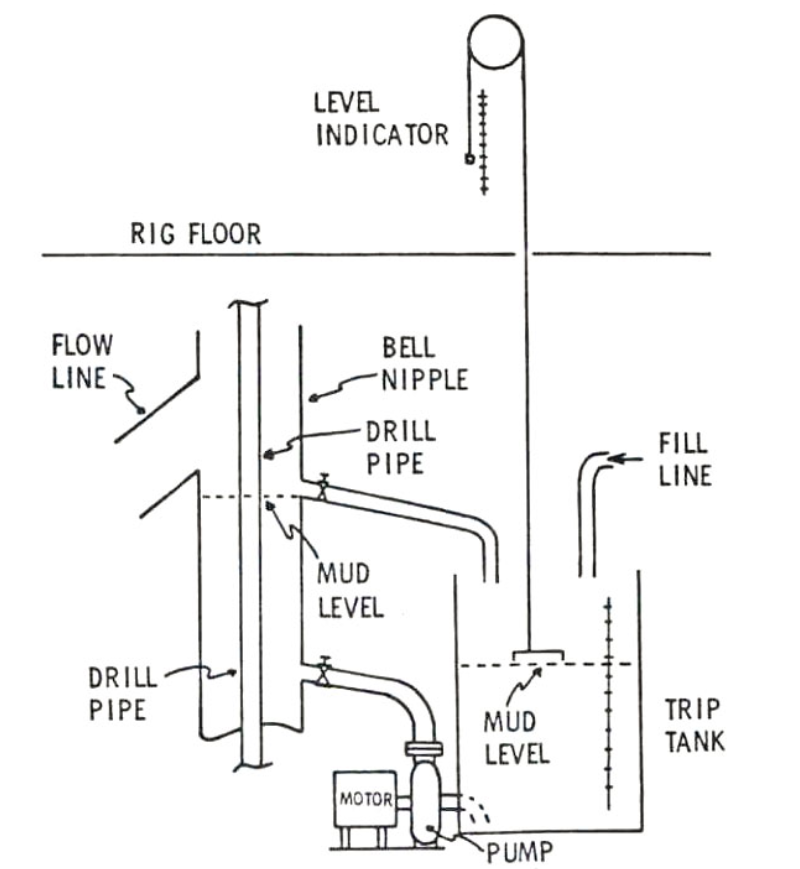

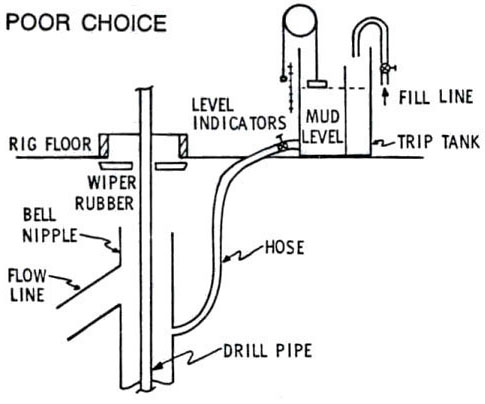

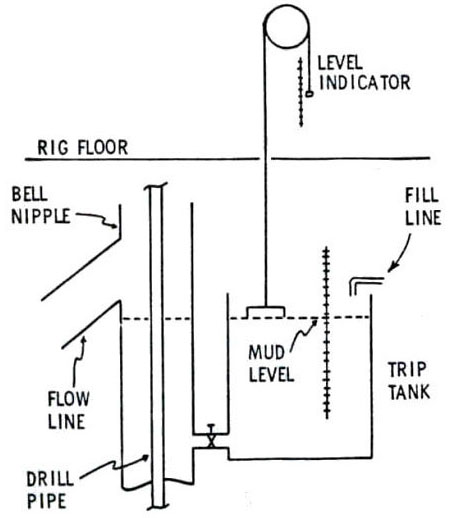

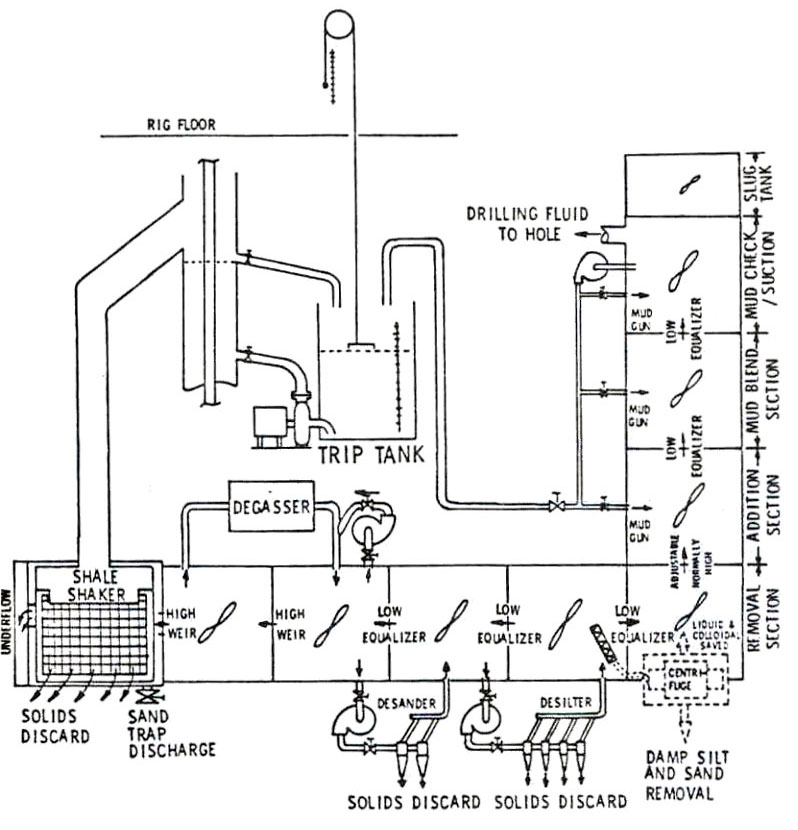

If the fluid level in the hole falls as the pipe is removed, a reduction in bottom hole pressure will occur. If the magnitude of the reduction exceeds the trip margin or safety overbalance factor, a well kick may occur (this is considered one of the major causes of kicks). The hole must be kept full with a lined-up trip tank that can be monitored to ensure that the hole is taking the correct amount of mud. It can be detected if the hole fails to take the correct mud volume. A trip tank lineup is shown in Fig 1.

Dimensions

- Trip tank dimensions are a compromise between reading 100 liters variations and having to fill the tank too often.

- Usually, Drilling Trip Tanks are dimensioned to achieve a 3 inches height variation for a 5 DP stand.

- The Centrifugal pump must have a sufficient flow rate to empty the tank in a few minutes.

- Many oil and gas companies‘ well Control policy stipulates that the minimum capacity of trip tank should be 5 m3 (30 bbls).

Level Indicator

- The Level indicator is a float connected to a graduated gauge stick on the rig floor and visible to the driller.

- Modern systems have the float connected to an electronic gauge or ultrasonic device.

Configuration

Gravity Trip Tank

Trip tank with centrifugal pump

Useful Tips

- While pipe tripping, for the first 5 to 10 stands off the bottom, monitors the hole through the rotary. This checks that the annulus falls as the drill pipe is removed from the hole. The pipe wiper should be installed only after the first stands have been pulled. The trip tank should not be overfilled at this stage to ensure that swabbing is indicated, should it occur. The circulating pump should be switched off at this stage, and the hole filled from the trip tank after each stand.

- At any stage while tripping out of the hole, and if the hole does not take the correct volume of drilling mud, the pipe should be run back to the bottom using the trip tank and bottoms-up circulated.

- In stripping operations, line up choke manifold so that returns are taken to the trip tank allowing accurate measurements to be recorded. Preference is to have a calibrated stripping tank taken off from the trip tank. If this is not installed, the worksheet will reflect any net gain over calculated/predetermined closed-end pipe displacement.

- A trip tank and pit watcher should be considered if vessel movement creates any problem in measuring drilling fluid requirements on trips.

- It is recommended for floating drilling units that flow checks be performed on the trip tank with the hole fill pump circulating across the bell nipple to eliminate rig motion as much as possible.

- In any shut-in procedure, it is prudent to line up the annulus to the trip tank above the annular BOP or preventer rams. This will assist in double-checking to see if they are leaking.

- In Choke Drill, it is desirable to discharge into a trip tank to accurately monitor flow rates for correlation with choke opening, pump rates, and pressure drops in the Drilling circulating system and across the choke. This is particularly important for subsea blowout preventer stacks in deep water, which may have significant circulating pressure losses in the choke lines.

- While drilling, the trip tank should be half full of mud when the pumps are off. During a connection, well should be lined up on the trip tank as the most likely time to swab or take a kick is when APL is lost with pumps off.

References:

- Well control For Drilling Rig Team

- Adco Drilling Manual

- ENI Rig Book