The principal factors governing the selection of type (or types) of drilling fluids (mud) to be used on a particular well are:

- The characteristics and properties of the formation to be drilled

- The quality and source of the water to be used in building the fluid

- The ecological and environmental considerations

- Well Blowout

- Jar Intensifier

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

Continuous-Phase Classification.

Drilling fluids are categorized according to their continuous phase so that there are:

- Water-based fluids

- Oil Based Drilling Mud

- Pneumatic (gas) fluids

Consider a drop of a drilling fluid. If one could go from a point in one phase to any other point in that same phase, then it is said to be continuous. If one had to cross one phase to get back to the previous phase, then that phase is discontinuous. Solids are always a discontinuous phase. Therefore, drilling fluids are designated by their continuous phase.

Water-based drilling mud types are the most commonly used fluids, while oil-based muds are more expensive and require more environmental considerations (Benefits Of OBM over WBM). The use of pneumatic drilling fluids (i.e., air, gas, and foam) is limited to depleted zones or areas where the formations are low pressured (although with underbalanced-drilling equipment, higher pressured zones can now be drilled without the need for pneumatic drilling fluids). In water-based fluids, the solid particles are suspended in water or brine, while in oil-based muds the particles are suspended in oil. When pneumatic drilling fluids are used, the rock fragments or drill cuttings are removed by a high-velocity stream of air or natural gas. Foaming agents are added to remove minor inflows of water (Darley and Gray 1988).

Water-Based Fluids.

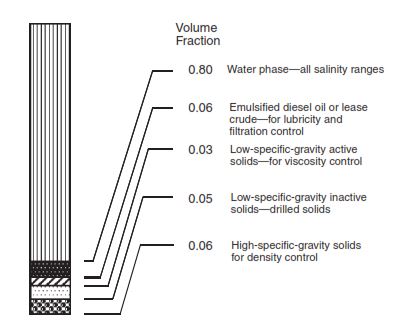

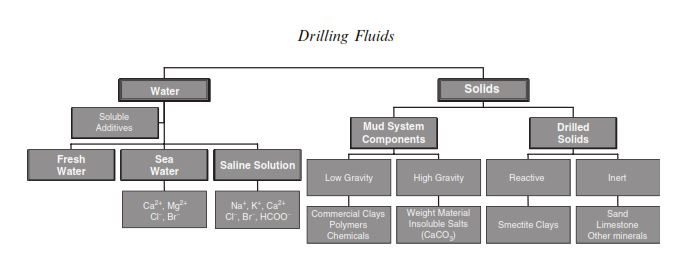

The majority of wells are drilled with water-based drilling fluids. The base fluid may be freshwater, saltwater, brine, or saturated brine. A typical water-based mud composition is illustrated in Fig. 1. Water-based drilling fluids range from native muds to lightly treated fluids to the more heavily treated, inhibitive fluids. They are divided into three major subclassifications:

- Inhibitive

- Noninhibitive

- Polymer

Inhibitive drilling fluids type retard clay swelling (i.e., the ability of active clays to hydrate is greatly reduced). For this reason, inhibitive fluids are used for drilling hydratable-clay zones. The ability of the formation to absorb water is not inhibited when noninhibitive fluids are used. The term noninhibitive refers to the lack or absence of those specific ions (sodium, calcium, and potassium) that are present in inhibitive fluids. Inhibitive fluid systems do not use chemical dispersants (thinners) or inhibitive ions, but native waters. Polymer fluids may be inhibitive or noninhibitive depending upon whether an inhibitive cation is used.

The Dispersed Bentonitic

These are fluids that are required for drilling deeper weels and there is a need of controlling its properties, i.e., weight, rheology and fluid loss. This type of water-based mud requires more attention for its properties & PH so using chemical thinners, such as lignosulfonate, lignite, or tannins & alkalinity control chemicals such as caustic soda will help in such a job.

Bentonite does not yield when the chloride content is above about 5000 mg/L. It becomes inert and acts like a drill solid.

Saltwater Drilling Fluids.

Saltwater drilling fluids are used for shale inhibition and for drilling salt formations. They are also known to inhibit hydrates (ice-like formations of gas and water) from forming, which can accumulate around subsea wellheads and well-control equipment, blocking lines and impeding critical operations.

This type of drilling mud is also applicable when drilling salt formations (no fresh water is available or selected for one of the mud systems listed below). The most common workover system is saturated sodium chloride, using attapulgite or sepiolite clay augmented by polymers to maintain the mud properties.

Usually, while drilling offshore wells, oil & gas companies utilize seawater for the top hole water-based system, before switching to another mud type.

Inhibitive Drilling Fluids.

This type of mud is designed to reduce chemical reactions between the drilling fluid and the formation. Fluid formulations containing sodium, calcium, and/or potassium ions minimize shale hydration and swelling. Gypsum (“gyp”) drilling fluids are used for drilling anhydrite and gypsum formations. In known H2S environments, a high pH water-based fluid treated with scavengers, or an OBF with 4–6 ppb of excess lime, usually is the recommended drilling-fluid system.

Incorporating up to 10% oil in a water-based fluid to improve lubricity and inhibition was a long-standing drilling practice; however, the availability of glycol additives and high-performance SBFs makes oil additions unnecessary. Furthermore, the disposal of water-based fluids containing a measurable percentage of oil is closely regulated.

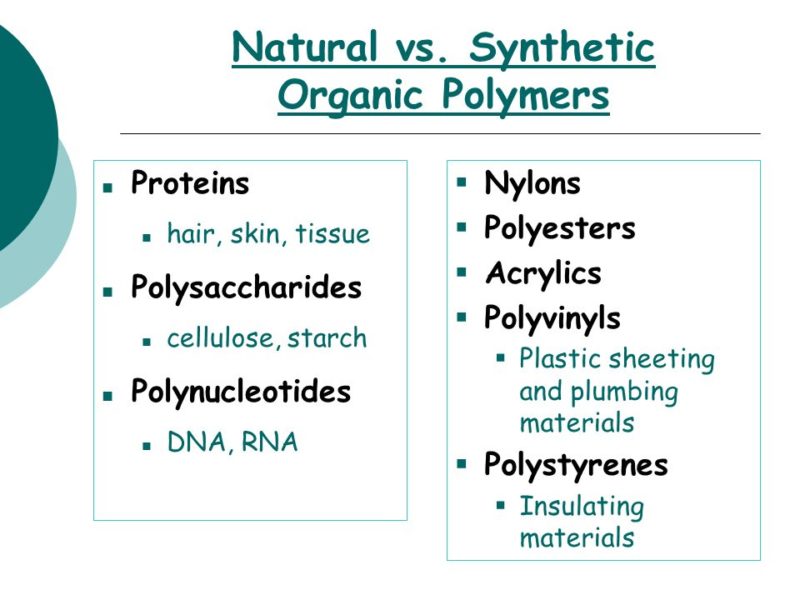

Organic and Synthetic Polymers.

Organic and synthetic polymers types are used to provide viscosity, fluid-loss control, shale inhibition, and prevention of clay dispersion in freshwater or saltwater-based drilling fluids. Most polymers are very effective even at low concentrations and can be run by themselves or added in small quantities to enhance or extend bentonite performance. Specially developed high-temperature polymers are available to help overcome gelation issues. Polymers function in several ways. Some polymers actually hydrate and swell in much the same manner as conventional clay materials. By doing this they thicken the water phase, making the escape of this water into the formation or into the clay structure more difficult, thereby preventing swelling. Large, high molecular-weight polymers will bond onto clay surfaces and literally surround and isolate the clay/shale particle. This is referred to as encapsulation.

Smaller polymers with low molecular weight will attach to exposed broken-edge bond sites and block the intrusion of hydrating water from the continuous phase. Free water can still bond to exposed surfaces, but the interior regions of the clays will not be wetted or expanded.

A recently developed inhibitive polymer system relies on nonionic materials that behave in much the same way as inhibitive water-based muds, because of hydrogen bonding. The advantage of this system is the ability to maintain a moderate concentration without raising the viscosity to undesirable levels. Excess polymeric material remains available to handle freshly drilled solids.

Membrane-Efficient Water-Based Drilling Fluids.

Wellbore instability predominantly occurs in shales that overlay reservoirs and is an industry-wide problem that affects exploration through to development drilling. Shales are fine-grained with high clay content, low permeability, and are chemically reactive with incompatible drilling fluids. The significant drilling fluid/shale interaction mechanisms are hydraulic or mud-pressure penetration, chemical potential, and swelling/hydration stresses.

When drilling with the improperly designed types of drilling fluids, shales without effective osmotic membranes progressively imbibe water, which leads to mud-pressure penetration. Consequently, the net radial mud support changes over a period of time, and near-wellbore formation pore pressure increases. This reduces formation strength and leads to borehole instability.

In most cases, the two most relevant mechanisms for water transport into and out of shale are the hydraulic pressure difference between the wellbore pressure (drilling-fluid density) and the shale pore pressure; and the chemical potential difference (i.e., the water activity) between the drilling fluid and the shale.

The fine pore size and negative charge of clay on pore surfaces cause argillaceous materials to exhibit membrane behavior. The efficiency is a measure of the capacity of the membrane to sustain osmotic pressure between the drilling fluid and shale formation.

If the water activity of the drilling fluid is lower than the formation water activity, an osmotic outflow of pore fluid from the formation, because of the chemical potential mechanism, will lessen the increase in pore pressure resulting from mud-pressure penetration. If the osmotic outflow is greater than the inflow as a result of mud pressure penetration, there will be a net flow of water out of the formation into the wellbore. This will result in the lowering of the pore fluid pressure below the in-situ value. The associated increase in the effective mud support will lead to an improvement in the stability of the wellbore.

One of the key parameters that can be manipulated to increase the osmotic outflow is membrane efficiency. The osmotic outflow increases with increasing membrane efficiency. In most conventional water-based fluids, the membrane efficiency is low. Therefore, even if the water activity of the drilling fluid is maintained significantly lower (with a high salt concentration) than the shale-water activity, the osmotic outflow may be negligible because of the low membrane efficiency.

As a result of extensive testing, three new generations of water-based drilling fluid systems with high membrane efficiencies (greater than 80%) have been developed, including a 12% NaCl system that generated a membrane efficiency of approximately 85%. Such systems hold promise for operations where OBFs and SBFs are unsuitable or prohibited because of drilling conditions and/or regulations.

Oil Based Drilling Fluids (Mud) Types

Normally, the high salinity water phase of an invert emulsion or SBF helps stabilize reactive shale and prevent swelling. However, drilling fluids formulated with diesel or synthetic-based oil and no water phase are used to drill long shale intervals where the salinity of the formation water is highly variable. By eliminating the water phase altogether, the all-oil drilling fluid preserves shale stability throughout the interval. These drilling fluid systems are commonly used in eastern Venezuela to drill the Caripita shale, which may be up to 10,000 ft thick.

The current base oils in use are:

- Paraffin (alkanes). These oils have carbon-hydrogen single bonds and are either linear (normal), branched (iso), or cyclic (ring) with carbon chain link of C10 to C22.

- Olephins (alkenes). These oils have carbon-hydrogen double bonds, either alpha olephins with the double bond between the number 1 and number 2 carbon or internal olephins with the double bond moved internally and carbon chain lengths of C15 to C18.

- Esters. These oils are modified vegetable oils, primarily from palm oil.

Invert Emulsion Drilling Muds Type

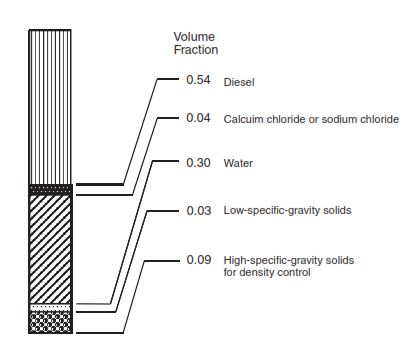

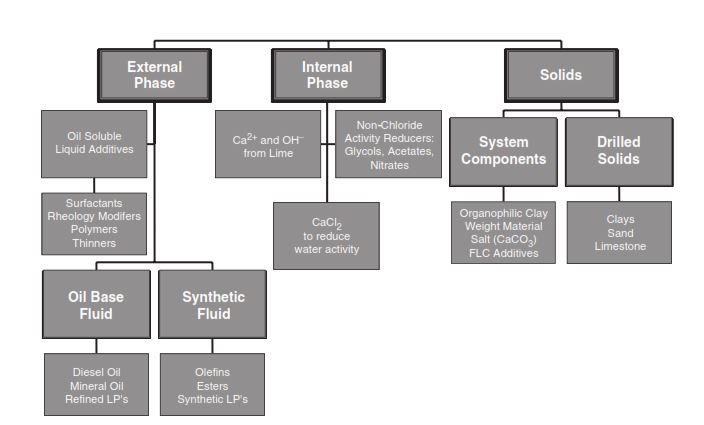

Diesel and mineral oil OBFs—also called “invert emulsions”—are inhibitive, resistant to contaminants, stable at high temperatures and pressures, lubricious, and noncorrosive. A typical oil-based mud composition is illustrated in Fig. 2. Onshore, they are the fluids of choice for drilling troublesome shale sections, extended-reach wells that would be otherwise prone to pipe-sticking problems, and dangerous HP/HT H2S wells. The drilling efficiency of an OBF system can save days, perhaps weeks, on the time required to drill the well.

These drilling fluid systems types are also subject to stringent disposal regulations because of their toxicity. Mineral oil formulations are considered less toxic than diesel-based fluids, but not a suitable alternative where “greener” SBFs are available. The use of diesel or mineral-oil-based fluids is absolutely prohibited in some areas.

The oil/water ratios typically range from 90:10 to 60:40, though both oil and water percentages can be increased beyond these ranges. Generally, the higher the percentage of water, the thicker the drilling fluid. High salinity levels in the water phase dehydrate and harden reactive shales by imposing osmotic pressures.

The basic components of an invert-emulsion drilling fluid type include diesel or mineral oil, brine (usually calcium chloride), emulsifiers, oil-wetting agents, organophilic clay, filtration-control additives, and slaked lime. Relaxed OBFs are formulated without filtration-control additives and have a loose emulsion.

The primary emulsifiers are calcium-based soaps. Secondary emulsifiers enhance temperature stability and are tall oils. In order to make the clays and lignites oil-soluble, a tallow derivative is grafted onto them. The tallow derivative is primarily responsible for extremely high viscosities at low temperatures, making traditional invert emulsion muds unsuitable for deepwater applications.

Synthetic-Based Drilling Fluids

Synthetic-based drilling fluids types were developed to provide the highly regarded drilling-performance characteristics of conventional OBFs while significantly reducing the toxicity of the base fluid. Consequently, SBFs are used almost universally offshore and they continue to meet the increasingly rigorous toxicity standards imposed by regulatory agencies.

The cost-per-barrel for an SBF is considerably higher than that of an equivalent-density water-based fluid, but because synthetics facilitate high ROPs and minimize wellbore-instability problems, the overall well-construction costs are generally less, unless there is a catastrophic lost-circulation occurrence.

Emulsion-Based Drilling Fluids (EBFs).

In early 2002, an SBF formulated with an ester/IO blend became widely used, especially in deepwater operations where temperatures range from 40 to 350°F on a given well. The fluid contains no commercial clays or treated lignites; rheological and fluid-loss-control properties are maintained with specially designed fatty acids and surfactants. The system provides stable viscosity and flat rheological properties over a wide range of temperatures.

Drilling Fluid gel strengths develop quickly but are extremely shear-sensitive. As a result, pressures related to breaking circulation, pipe tripping or running casing, cementing, and drilling ECD are significantly lower than pressures that occur with conventional invert emulsion fluids. Lost circulation incidents appear to occur less frequently and with a lesser degree of severity where EBFs are used.

The EBF performs well from an environmental perspective and has met or surpassed stringent oil-retained-on cuttings regulations governing cuttings discharge in the GOM. The EBF is highly water and solids-tolerant and responds rapidly to treatment.

Pneumatic Drilling Fluid Types.

Pneumatic drilling fluids are most commonly used in dry, hard formations such as limestone or dolomite. In pneumatic drilling-fluid systems, air compressors circulate air through the drill string and up the annulus to a rotating head. The return “fluid” is then diverted by the rotating head to a flowline leading some distance from the rig to protect personnel from the risk of explosion. Gas from a pressured natural gas source nearby may be substituted for air. Both air and gas drilling is subject to downhole ignition and explosion risks. Sometimes, nitrogen — either from cryogenic sources or generated using membrane systems — is substituted for the pneumatic fluid. Pneumatic drilling fluids are considered to be nondamaging to productive formations.

As mentioned above, dry gas drilling is best suited for formations that have a minimal amount of water. Once water is experienced while operations, the dry gas system is switched by the addition of a surfactant and called a “mist” system. Increasing amounts of water in the formation require additional amounts of foaming surfactants and polymer foam stabilizers.

Silicate-Based Drilling Mud Type.

Field applications of sodium silicate drilling fluids indicate that they appear to provide a sealing effect within shale pore throats and may also increase membrane efficiency (the mobility of solutes through a shale pore network) (Mody 1993). Contact with calcium or magnesium ions, or the decrease in pH caused by dilution of fluid filtrate with pore fluid, may cause the electrolytes to precipitate (Bland 2002). Shale permeability is therefore reduced. However, the excellent shale inhibition characteristics of silicate drilling-fluid systems may be outweighed by other perceived deficiencies in lubricity, thermal stability, and the necessity for a high pH.

Typically, the silicate-based fluid system creates a physical membrane, which, in conjunction with the soluble sodium silicate or potassium silicate, provides primary shale inhibition. The wellbore becomes pressure-isolated so that filtrate invasion is minimal. Polyglycols may provide secondary inhibition, improve lubricity and filtration control, and stabilize the drilling fluid’s physical properties. Polyglycols can withstand the high pH environment of silicate fluids better than conventional lubricants that may hydrolyze at high pH.

Silicate-based fluids have been used successfully in drilling highly reactive gumbo clays in the top hole interval and as an alternative inhibitive fluid in areas where invert-emulsion fluids are prohibited. They may also be useful for drilling highly dispersible formations such as chalk and have been used to stabilize unconsolidated sands.

Conclusion

Detailed classification schemes for liquid drilling fluids are employed that describe the composition of the fluids more precisely. One such classification scheme is shown in the figures below. An even more precise classification scheme is described in Table below, which includes the mud systems most commonly used today, along with their principal components and general characteristics [adapted from Darley & Gray].

| Mud Type | Principal Components | General Characteristics |

|---|---|---|

| Simple freshwater | Freshwater | Low cost, onshore applications; fast drilling in stable formations; need space for solids settling, flocculants may be used |

| Simple seawater | Seawater | Low cost, offshore applications |

| Spud mud | Bentonite, water | Low cost, surface hole |

| Saltwater | Seawater, brine or saturated saltwater; saltwater clay, starch, cellulosic polymer | Moderate cost, drilling salt and workovers |

| Lime or gyp | Fresh or brackish water; bentonite lime, or gypsum, lignosulfonate | Moderate cost, shale drilling; simple maintenance, high temp, tolerance to salt, anhydrite, cement, drilled solids |

| Lignite or lignosulfonate (chrome or chrome-free) | Fresh or brackish water; bentonite, caustic, lignite or lignosulfonate | Moderate cost, shale drilling; simple maintenance, high temp, tolerance to salt, anhydrite, cement |

| Potassium | Potassium chloride; acrylic, bio or cellulosic polymer, some bentonite | Moderate cost, hole stability; low tolerance to drilled solids, high pH |

| Low solids (‘‘non-dispersed’’ when weighted up) | Fresh to high saltwater; polymer, some bentonite | High cost, hole stability; low tolerance to drilled solids, cement, and divalent salts |

| Oil | Weathered (oxidized) crude oil; asphaltic crude, soap, water 2–5% | Moderate cost, low-press well completions and workovers, low-press shallow reservoirs; water used to increase density and cuttings-carrying capacity; strong environmental restrictions may apply |

| Asphaltic | Diesel oil; asphalt emulsifiers, water 2–5% | Moderate cost, any applications to 600 F; strong environmental restrictions may apply |

| Invert Emulsion | Diesel, mineral, or low-toxicity mineral oil; emulsifiers, organophilic clay, modified resins, and soaps, 5–40% brine | High cost, any applications to at least 450 F; low maintenance, environmental restrictions |

| Synthetic | Synthetic hydrocarbons or esters; other products same as an invert emulsion | Highest cost, any applications to at least 450 F; low maintenance |

The content provided is really of good help and promotes capacity building .I am much grateful.thanks alot.