Underbalanced drilling technique involves drilling the formation with drilling fluids having lesser hydrostatic pressure than the formation pressure. The lesser hydrostatic pressure of drilling fluids can occur naturally or it can be formulated by adding certain substances like methane, air, or nitrogen (N2) in the liquid phase. This technique results in the inflow of formation fluids that are circulated in the well and controlled on the surface.

Features of Underbalanced Drilling:

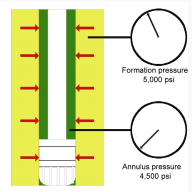

Mainly the pressures that contribute towards the hydrostatic pressure of the drilling fluid or the bottom hole pressure include hydrostatic pressure of fluid column, associated frictional pressures, and the choke pressure as shown in Figure 1. The pressure equation for the underbalanced drilling method is stated below:

P reservoir ˃ P bottom hole = P hydrostatic + P friction + P choke

The well-control mechanism is of great concern in underbalanced drilling as the fluid pressure is not controlling the well in this technique rather following three mechanisms are used for primary well control in underbalanced drilling. However; secondary well control is Blow Out Preventor stack (BOP) which is similar to conventional drilling.

- Passive: Well, is controlled by the density of the drilling mud used plus the density of the cuttings that are drilled.

- Dynamic: Friction pressure is another factor contributing towards well control. It is because of the circulation of fluids inside the well.

- Active: Choke pressure is the main factor contributing towards the well control mechanism. It is the positive pressure at the surface that arises because of the closure of the production string at the surface.

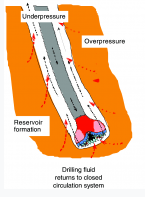

Underbalanced drilling helps control the build-up of filter cake around the formation because of the lesser hydrostatic pressure of the drilling fluids. Additionally; it restricts the movement of mud or drilling solids into the formation that helps improve the productivity of the well and minimize the problems related to drilling. The circulation system of underbalanced drilling is shown in Figure 2.

Underbalanced Drilling – Reasons to Consider:

Underbalanced drilling is an unconventional method of drilling that is used because of its ability to maximize the recovery of hydrocarbons to its potential and decreases the risks related to pressure during the drilling. Both of these reasons make underbalanced drilling more convenient and economical than conventional drilling.

However; there are some specific benefits and drawbacks related to underbalanced drilling as stated:

Benefits of underbalanced drilling include:

- Increased Rate of Penetration (ROP).

- Damage to the formation is reduced.

- Differential sticking can be avoided.

- Increases the life of the bit.

- Losses during circulation of drilling fluids are minimized.

Drawbacks of underbalanced drilling involves:

- Wellbore Stability of the open hole wellbore is at risk.

- Addition of certain substances like nitrogen to make the drill mud light adds up to the cost of drilling (check also oil well drilling well cost per foot).

- Drag and torque increases.

- Potential risk of borehole erosion.

Enhanced Recovery of Hydrocarbons:

Early Hydrocarbon Production:

As we know that, in underbalanced drilling, the hydrostatic pressure of the fluid column is less than the formation pressure so as soon as the reservoir is penetrated, hydrocarbons begin to flow in the production string. If the storage of those hydrocarbons can be handled properly at the surface, then it turns out to be an economical method.

Decreased Stimulation Operations:

As stated above, an underbalanced drilling filter cake or the invasion of drilling fluid solids does not affect the reservoir so the stimulation operations like acidic flooding and hydro fracking of the reservoir can be avoided that reduces the cost of drilling making it more economical.

Increased Recovery of Hydrocarbons:

Underbalanced drilling contributes towards the extension of the life of a well. Recovery of the remaining hydrocarbons is possible because of the ability of underbalanced drilling to drill infill wells in the depleted reservoirs. This enhanced recovery and increased productivity of the well leads towards a lower drawdown that can resolve the issue of water coning as well.

Knowledge of Reservoir Characteristics:

The inflow of reservoir fluids during drilling helps investigate and analyze the fluids producing in real-time which in turn assists to decide the most productive layer of the reservoir. Additionally; well testing results can also be obtained while drilling. All these factors contribute towards a better understanding of the reservoir.

Reduction in Drilling Problems Related to Pressure:

Resolution of Drill String Sticking Problem:

In conventional drilling, often drill string gets stuck because of the higher hydrostatic pressure of the fluid column and the formation of filter cake but this problem is resolved in underbalanced drilling because of the absence of the reasons elaborated above. This differential sticking problem is usually faced when drilling with coiled tubing because coiled tubing lacks connection of the joints that enhances the standoff in the borehole for a longer time.

Reduction in Drilling Fluid Loss:

Because the hydrostatic pressure of the fluid column is less in underbalanced drilling than the formation pressure, the problem of fluid circulation mud losses is controlled in this type of drilling. This also protects the structure of the reservoir by protecting the fractures in the formation.

Increase in Rate of Penetration:

The rate of penetration is considerably improved by maintaining a lower hydrostatic pressure in the annulus and in addition to that bit life is also increased. Bit life is increased because of the factors like enhanced rate of penetration and the removal of drill bit cuttings effectively and in a timely manner. From the field data, it has been analyzed that when drilling underbalanced a whole section of a formation can be drilled using only one drilling bit; however, the same section might use 3 to 5 bits in overbalanced drilling. Furthermore; the rate of penetration nearly doubles in this type of unconventional drilling.

References:

- (Underbalanced drilling (UBD), 2021)

Very nice notes,i will be follow you and read whenever you are post it.contniue such like. This indicate some persons were open minded for the world wide,for sustainable development goals for 2030, while others are narrow minded.

Thank u alot!!!!

Thank you for the article. It’s very interesting for me. I’m a drilling engineer and I like this technology of drilling.