The purpose of the drilling bottom hole assembly BHA is to drill a useful vertical hole with full gauge, smooth bore and free of doglegs and ledges.

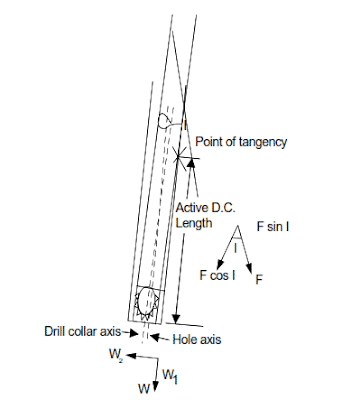

From the below drawing which shows the simplest bottom hole assembly (slick assembly) which consists of a bit and drill collars and no stabilizers, you will notice the following:

- In the vicinity of the bit, the string does not contact the wall of the hole.

- At some distance above the bit, the string contacts the wall.

- Above the point of contact the string lies on the low side of the hole.

Drilling Bottom Hole Assembly BHA Tendency

With no weight on the drilling bit, the only force acting on the bit is the force F which is the weight of the portion of the string between the bit and the point of contact. This force can be resolved into two components:

- F cost I along the center line of the hole

- F sin I perpendicular to the hole axis: The force is a beneficial force because it tends to bring the hole toward vertical.

The second force acting on the drilling Bottom Hole Assembly BHA is the weight on bit W, which can be resolved into components

The force component W2 is responsible for hole deviation and its magnitude increases with increasing clearance between drill collars and hole and with increases in weight on bit. The magnitude and direction of the resultant hole deviation is dependent on the difference between W2 and F sin I.

The major source of natural hole deviation is formation characteristics. Laminated structures composed of alternating soft and hard bands can cause hole deviation. Practical experience has shown that laminated dipping formations cause hole deviation. When the dip angle is less than 45 degree, the drilling bit tends to drill up dip. When the dip angle is greater than 45 degree, the drilling bit tends to drill down dip.