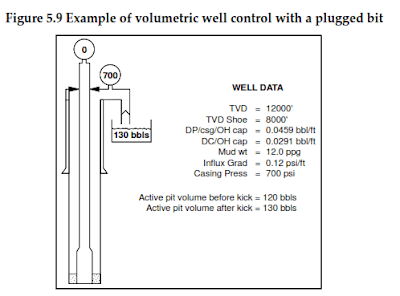

The volumetric method is mostly used in workover and production well control operations. It allows the gas to migrate (gas kick behavior) to the surface under control. The gas needs to migrate at over (approx.) 1000′ per hour.

To allow the bubble to expand the casing pressure is held constant for a given volume of mud bled off. This operation is repeated, holding an ever-increasing casing pressure until the gas reaches the surface (Holding Bottom Hole Pressure constant).

Applications

- A gas kick (well kicks)+ migration + plugged drill string (only casing pressure can be read).

- No drill string in the well

- production packer leaking

- wireline logging

- swabbed gas migrating.

Procedures & Calculations

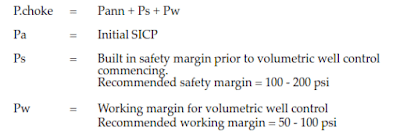

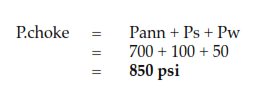

The first step in volumetric well control method is to calculate safety margins and working margins

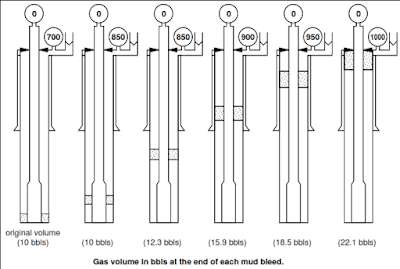

Secondly, allow the casing pressure to increase to 850 psi.

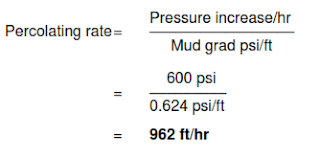

Note the time taken for this pressure increase then estimate the percolating rate in ft/hr. If Pressure increased by 150 psi in 15 minutes it means 600 psi/hr

So it will take approximately 12 hours to get the influx to the surface and it should also be noted percolating rate may increase when gas is close to the surface.

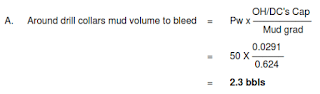

Thirdly, When casing pressure is at 850 psi

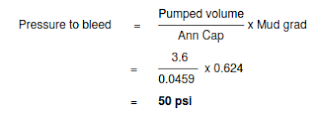

- Bleed off at choke a volume of mud equal to the working pressure (50 psi).

- Hold Casing pressure constant at 850 psi during this operation.

- After 50 psi of mud equivalent has been bled off at choke allow the gas to migrate unexpanded until a further 50 psi of overbalance is attained.

- Bleed off 50 psi equivalent mud at choke and repeat procedure until gas is at choke manifold.

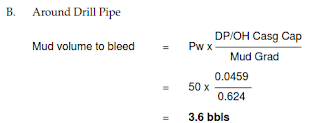

- Four bleeds are shown. Depending upon the size of the volume bled and the well depth more or less

Important Points

1. Bleed mud at constant choke pressure using the manual choke. Ensure crew trained not to bleed off faster than this as more you could induce more influx . A major problem with the method could be boredom, careful records must be kept of pressure and volumes.

2. Gas may not conveniently migrate up the well in one bubble. As soon as gas reached choke, stop bleeding until rest of gas catches up. This may build up an unacceptable overbalance and each situation will have to be judged on the operational merits of the situation.

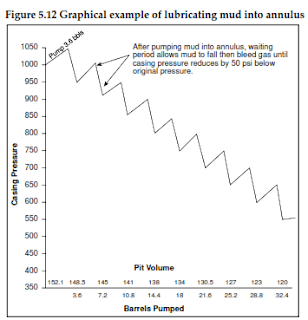

Fourthly, lubrication in volumetric well control method

Once gas is at choke stop the bleed operation and start pumping mud into the well using the kill line. The procedure for lubrication:

- Let kill and choke line pressure equalize

- Open kill line stack valves.

- Pump slowly into the kill line.

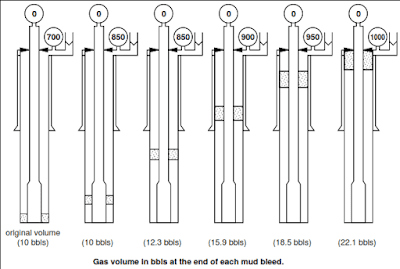

- Pump 3.6 bbls mud into the annulus.

- Allow the mud time to fall through the gas.

- Bleed-off pressure at the choke = the hydrostatic pressure of pumped mud.

- Repeat the above process till all the gas has been replaced with mud (approximately 22.1 bbls).

Note: Pit volume should return to the same volume in the active pit before the kick. Original Pit Volume = 120 bbls – Pit volume after kick and bleed = 152.1 bbls

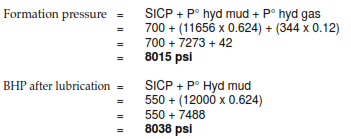

Fifthly, Switch to Kill Mud After Finishing the Volumetric Well Control Method

Now the well must be circulated to kill mud. This can be done by running wireline and perforating drill pipe or drill collars. If all the gas has been bled from the annulus then SICP can be used to calculate the kill mud.