When it comes to oil and gas drilling, one of the most critical pieces of equipment is the wear bushing or the bore protector. This small, yet essential component helps to protect the drill string from wear and tear and ultimately helps to keep the entire operation running smoothly. But what exactly is a wear bushing, and how does it work? In this article, we’ll take a closer look at this crucial piece of equipment and explain how it helps to keep drill rig types running smoothly.

Application

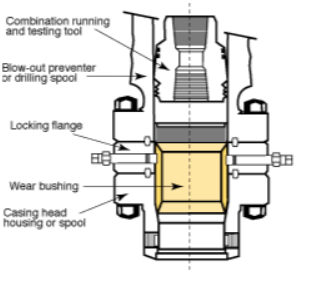

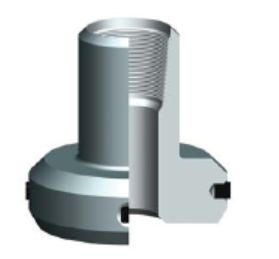

A wear bushing, or sleeve, is installed in the casing head housing, or indeed in any compact or casing head spool, to protect the hanger landing preparations from damage while the drill string, tools, or other tubulars are run through, or rotated in, the wellhead.

Installation Of Wear Bushing

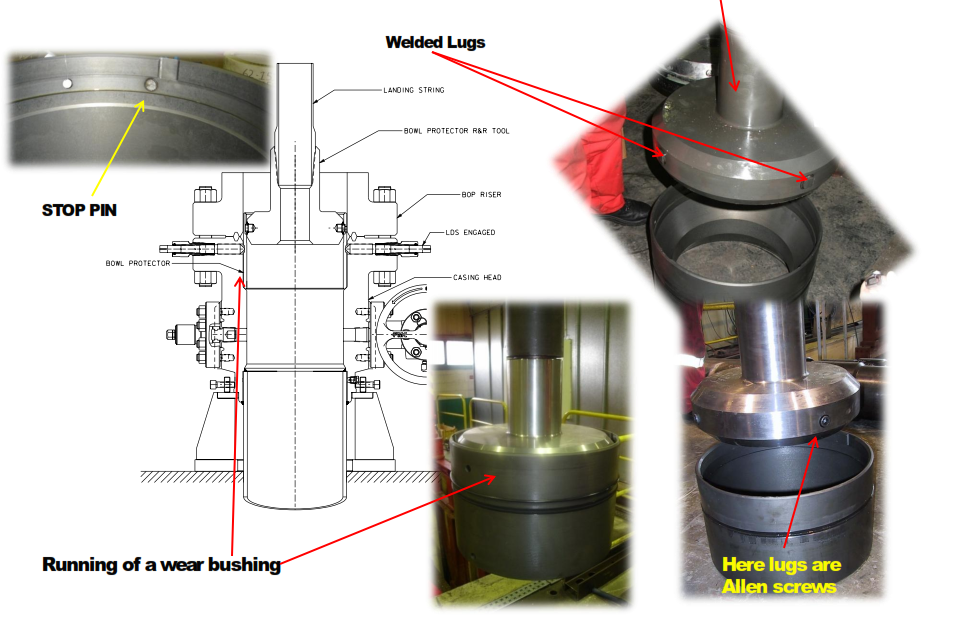

In some systems, the sleeve is held in place by a set of tie-down bolts contained either in the top flange of the housing or in a separate hold-down flange installed between the housing and the BOP drilling spool – see Figure 1. In other systems, it is held in place by a snap ring.

As the wean bushing occupies the same profile as the casing hanger, it is exceedingly important to remember that it must be removed before running the next casing string type; otherwise, the hanger cannot be landed. A memory prompt is usually provided as a notice hung from the BOP panel with the following note – ‘WEAR BUSHING INSTALLED’.

It is usually installed or retrieved by the hanger running tool or by a combination running/test tool, which also allows pressure testing of the BOP/wellhead connection during one run.

Conclusion:

- Run and set into the top bowl to protect the wellhead from wear during the drilling operation.

- Lock screws tightened to contact bore protectors can be used if the casing head has this feature.

- Most wellheads from major manufacturers incorporate the wear bushing lock assembly into the body of the spool using a “J” slot system.

- We shall remove them before the casing running.