Well Planning is perhaps the most demanding aspect of drilling engineering. It requires the integration of engineering principles, corporate or personal philosophies, and experience factors. Although well-planning methods and practices may vary within the drilling industry, the result should be a safely drilled, minimum-cost hole that satisfies the reservoir engineer’s oil/gas production requirements.

Objective

- Safe

- Minimum cost

- Usable

Unfortunately, it is not always possible to accomplish these objectives on each well because of constraints based on:

- Geology

- Drilling equipment

- Temperature

- Casing limitations

- Hole sizing

- Budget

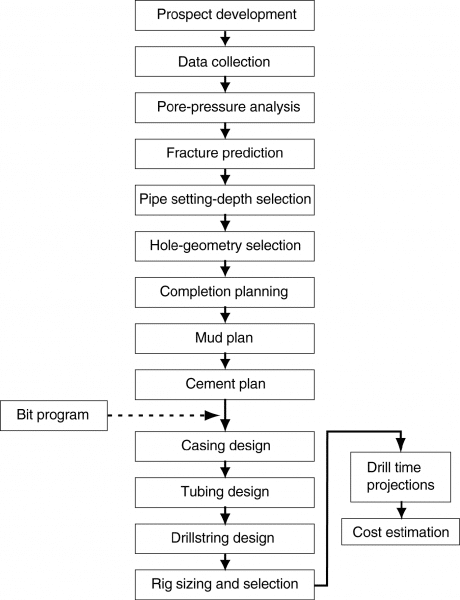

Well Planning Steps

Location

The first thing to do is to define a local coordinate system originating at the structure reference point. In many land wells, this will be the surface location. The target location is then converted to this local coordinate system if necessary.

Target Size -Cost versus Accuracy

- In many cases, operator companies adopt an arbitrary in-house target size

- As the target size gets smaller due to certain limitations ( geological or political), you need to be more accurate, and costs will increase.

Good Communication

The first step of any plan to correct the azimuth of a well should always be consultation with the Geology Department.

Wellbore Profile

Knowing the position of the surface location and given the location of the Target, its TVD, and rectangular coordinates. Wells can be either:

- Straight

- Slant type

- “S” type

- Horizontal

The type of well profile selected will depend upon the well’s Geological objective and production mechanism.

Determining the Kick-off Point

The Kick-off point is selected by considering the geometrical well path and the geological characteristics. The optimum inclination of the well is a function of the maximum permissible build rate (and drop rate if applicable) and the location of the target

Build and Drop Rate

It will be determined by one or more of the following:

- The total depth of the well.

- Maximum Torque and Drag limitations.

- High dogleg severity in the build section of the well results in high torque and drag while drilling the remainder of the well. This can be a severe limiting factor in deeper wells.

- The formations through which the build section must pass. Higher build rates are often not possible to achieve in soft formations.

- Mechanical limitations of the drill string or casing pipe.

- Mechanical limitations of logging tools and production strings.

- Formation of “Keyseats” in the Kick-off arc.

Commonly in the range of 1.5° to 3° per 100 ft. Once the desired build rate and inclination have been established, the kick-off point can be determined.