Wireline conveyed perforating is an established, proven technique of unquestionable reliability. It is often the cheapest perforating method technique and more reliable than the alternatives. The consequences of a misfire are minimized by the ease with which guns can be pulled from the hole and re-run. Due to the gun’s weight, only a limited interval can be perforated during each run in the hole.

Long intervals must be perforated in several runs, of which only the first can be conducted under ideal conditions of underbalance. Depending on the depth and other considerations, such as delays in obtaining radio silence or statutory restrictions on using explosives at night, the operating time required per run can vary from less than an hour to several hours.

Therefore, perforating long intervals with wireline guns can take several days, which may be prohibitively expensive if a rig is on site. The use of wireline guns is the safest perforating technique available, with few reported incidents of unintentional detonation either at the surface or downhole. Wireline conveyed perforating does not require a rig on-site and is frequently used for perforating additional zones of producing wells.

The Perforating Gun Assembly & Mechanism

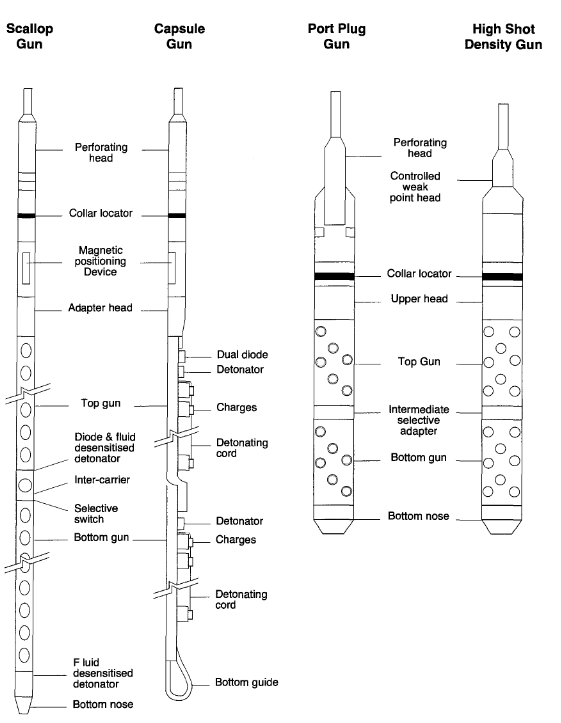

The wireline perforating gun assembly consists of a cable head, a collar locator or gamma ray tool, and spring or magnetic devices to position the gun in the borehole and the gun itself. Four main types of wireline perforating guns can be distinguished and are depicted in Fig. 1 . All are essentially similar in operation and differ only in how the components are assembled.

Cable Head

The cable head provides mechanical and electrical connections between the cable and the gun. The mechanical connection between the cable and head is weaker than the cable itself to allow the cable to be pulled free should the gun become stuck in the hole. It is commonly referred to as the weak point. The cable head is designed with a profiled neck to allow standard fishing equipment to recover tool strings should the weak point be broken. For casing guns run using a large cable, this neck has a smooth profile to allow engagement by an overshot/grapple assembly. In contrast, a standard wireline fishing neck is provided for small-diameter guns.

Collar Locator In Wireline Conveyed Perforating

The collar locator or gamma ray tool positions the gun at a precisely determined depth relative to open-hole log measurements or completion hardware. Gamma-ray tools are little used due to their fragile nature and the relative ease with which a collar log can be used for depth correlation. Typically, a gamma ray tool and collar locator (GR-CCL) are run in combination before the perforating run to allow the precise depth of casing pipe collars relative to the open hole evaluation logs to be determined.

The need for an additional GR-CCL run can be avoided by ensuring that a gamma ray tool is combined with the cement bond log of the production casing type. The collar depths are used to correct errors in in-depth measurements made while running the perforating gun into the hole. Suppose the open-hole gamma ray log does not have enough character to allow correlation with the casing collar log.

In that case, it may be necessary to run a neutron log with a casing collar log to determine the depths of the casing collars. Difficulties correlating different casing collar log runs can lead to errors in identifying individual collars when all casing joints are very similar in length. It is, therefore, customary to run a short joint (pup joint) in the casing string at the top of the reservoir interval. This ensures that casing collars are readily and rapidly identifiable, reducing the risk of perforating off-depth.

Positioning Device

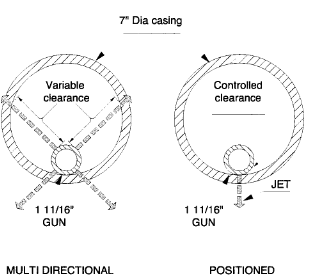

For smaller diameter guns, which do not perforate through 360°, positioning devices are placed below the collar locator to ensure that the gun is oriented in the correct azimuthal direction in the wellbore. When fired, the azimuthal position of the gun in the wellbore will determine the distance through the wellbore fluids that the shaped charge jet must travel before penetrating the casing Fig. 2.

In general, this distance should be minimized to achieve the maximum formation penetration and the optimum perforation performance. A spring or magnetic device is used to ensure that the gun is held against the casing, which minimizes the standoff between the gun body and the casing in the direction of the shots. Through tubing, perforation of the upper zones of a multiple completion requires that the shots are fired with an orientation that avoids damage to the long completion string.

The Wireline Conveyed Perforating Gun

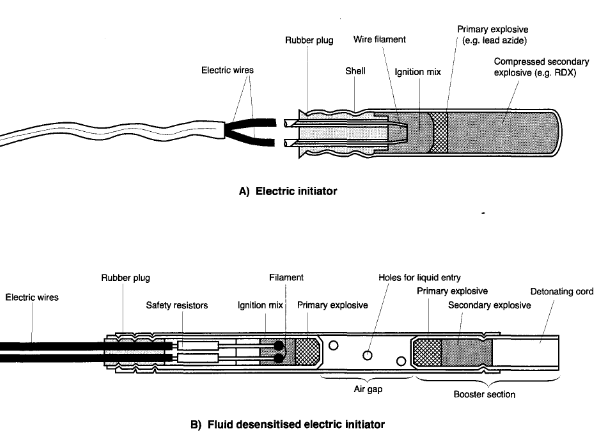

The gun is positioned at the bottom of the perforating assembly. The gun consists of an electrically actuated detonator, or blasting cap, connected to the end of a tube of explosives known as a detonating cord or prima cord Fig. 24 . The detonating cord travels the length of the gun. It is in physical contact with each of the shaped charges.

When the gun is fired, the blasting cap initiates the detonation of the prima cord, which in turn activates each of the shaped charges. In hollow carrier guns, the blasting cap is placed at the gun bottom, and the gun is fired from the bottom up. The detonator will not initiate the primacord if fluid is present due to leakage, preventing the low-order detonation and splitting of the gun that would result. Expendable and semi-expendable capsule-type guns have a blasting cap at the top and are fired from the top down. Suppose a continuous interval is to be perforated.

In that case, gun sections are usually connected together ballistically (when the detonation shock wave of one gun section directly initiates the detonation of the next) and fired as a single gun. Where multiple short intervals are to be perforated, guns can be combined and run together and then fired individually at the required depths. The design of the gun to be fired is achieved by using diodes and mechanical switches in the downhole gun.

Detonators In Wireline Conveyed Perforating

A conventional electric detonator typically contains a bridge wire in an ignition mix, plus a primer charge and a base charge. The primer charge is usually a sensitive explosive (e.g., lead azide). Such detonators are very sensitive and must be protected from any source that could provide power accidentally, such as radio transmissions.

To eliminate the requirement for radio silence, two perforating companies have developed detonators that contain no primary explosives. Both systems use the energy released when a capacitor charged to a high voltage is discharged through a thin conductor or foil to directly initiate high-order detonation of secondary explosives.

The design of these detonators is very similar to conventional detonators, except that no primary explosive is used. These systems require a minimum voltage of 150-200 volts DC at the cable head to operate the tool and to produce the 2500-3000 volts to which the capacitor will be charged. This compares with 10 volts AC or DC required for standard detonators and 1 volt for high-temperature detonators which do not contain internal safety resistors.

Testing the systems has shown them to be incapable of unintentional initiation even when exposed to powerful electrical and magnetic fields.

EBW system

With the EBW system, a downhole capacitor dumps stored electrical energy into the bridge wire of the detonator. This occurs so rapidly that the inertia of the bridge wire prevents it from blowing apart until after it has absorbed a large amount of energy. The shock wave released is powerful enough to initiate the secondary explosive contained in the detonator. In effect, the electrical energy dumped from the capacitor replaces the chemical energy released, which is the primary explosive in a conventional detonation.

SAFE system

This system consists of an exploding foil initiator (EFI) and an electronic cartridge (ESIC). When a high voltage is applied via the ESIC, the bridge section forms a plasma inflating the central sections of overlying plastic foil. The foil pushes through the center of a washer and slaps against a secondary explosive pellet with sufficient energy to detonate it.